Analysis of Hydrolysis Residues

Background on Hydrolysis Residues

Our Recommendations for Evaluating Hydrolysis Processes

We have a lot of experience in analysing many products (both liquid and solid) from biomass hydrolysis processes. These samples have covered a wide variety of starting feedstocks and hydrolysis processes and conditions. Below we recommend a set of Celignis analysis packages for getting the most detailed data about the whole conversion process:

(1) The Starting Feedstock

We recommend that analysis package P10 - Sugars, Lignin, Extractives, and Ash is used as this will fully remove the extractives prior to the hydrolysis stage meaning that you can be confident that the sugars reported in this package come from lignocellulose.

We would also recommend analysis package P12 - Sugars in Solvent Extract as this will report the amount of water-soluble carbohydrates in the sample. It is likely that water-soluble carbohydrates will be present in the liquid output of many hydrolysis processes and, if their concentrations are not known, it may be incorrectly inferred that such sugars present in the liquid must come from lignocellulose. However, if the water-soluble carbohydrate composition is known then these values can be substracted from the amounts of sugars in the hydrolysis liquid to determine the amount of true lignocellulosic sugars that are present.

Similarly, if you expect that there will be some starch in your sample then we also recommend that analysis package P14 - Starch Content is also undertaken as starch may also be removed and hydrolysed in many hydrolysis processes.

Additionally, if you are interested in the uronic acid composition of the biomass then we recommend analysis package P15 - Uronic Acids is also undertaken.

(2) The Liquid Product from Hydrolysis

For the most detailed results, we would recommend that the liquid output is analysed using analysis packages P13 - Sugars and Oligosaccharides in Solution, P22 - Organic Acids and Furans, and P15 - Uronic Acids. However, if uronic acids are expected to be very low in your original biomass sample then that analysis package may not need to be undertaken.

(3) The Solid Residue from Hydrolysis

As it is likely that most of the extractives will have been removed in the hydrolysis, it may not be necessary to remove or characterise these. Instead, we recommend that analysis package P9 - Lignocelullosic Sugars and Lignin is undertaken to determine the lignocellulosic composition of the residue. We would also recommend that analysis package P3 - Ash Content is also undertaken to see whether the hydrolysis process significantly changes the ash content of the sample. Also, if the fate of the uronic acids is of interest then analysis package P15 - Uronic Acids could be undertaken.

Celignis founder Daniel Hayes has considerable experience in the chemical and near-infrared analysis of residues from hydrolysis processes, in large part due to his participation in the DIBANET research project, funded by the European Union's 7th Framework Programme. That project involved the development of advanced technologies for the production of biofuels and valuable chemicals (including levuinic acid, formic acid, and furfural) from biomass.

Analysis of Hydrolysis Residues at Celignis

Celignis Analytical can determine the following properties of Hydrolysis Residues samples:

Lignocellulosic Properties of Hydrolysis Residues

Cellulose Content of Hydrolysis Residues

Click here to see the Celignis Analysis Packages that determine Cellulose Content

Request a QuoteCellulose Content

Hemicellulose Content of Hydrolysis Residues

Click here to see the Celignis Analysis Packages that determine Hemicellulose Content

Request a QuoteHemicellulose Content

Lignin Content of Hydrolysis Residues

Click here to see the Celignis Analysis Packages that determine Lignin Content

Request a QuoteLignin Content

Starch Content of Hydrolysis Residues

Click here to see the Celignis Analysis Packages that determine Starch Content

Request a QuoteStarch Content

Uronic Acid Content of Hydrolysis Residues

Click here to see the Celignis Analysis Packages that determine Uronic Acid Content

Request a QuoteUronic Acid Content

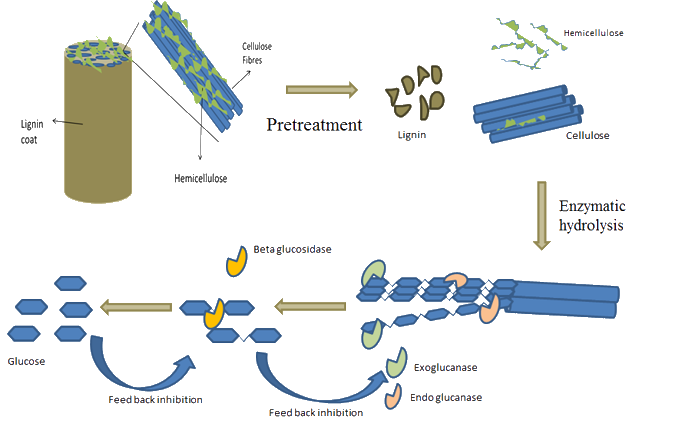

Enzymatic Hydrolysis of Hydrolysis Residues

Click here to see the Celignis Analysis Packages that determine Enzymatic Hydrolysis

Request a QuoteEnzymatic Hydrolysis

Bioenergy Properties of Hydrolysis Residues

Ash Content of Hydrolysis Residues

Click here to see the Celignis Analysis Packages that determine Ash Content

Request a QuoteAsh Content

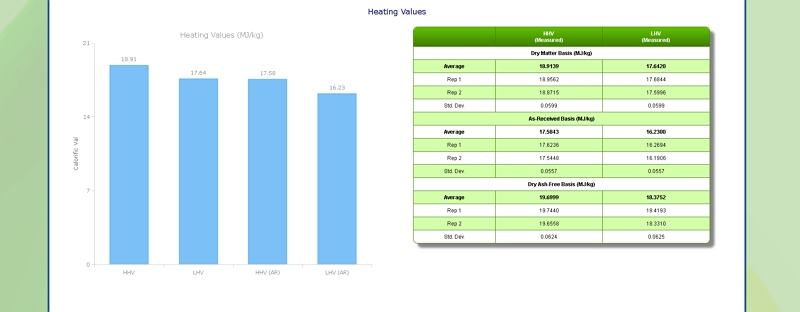

Heating (Calorific) Value of Hydrolysis Residues

However, the moisture content of the residue will be of key importance in determining the effective heating value of the sample.

Click here to see the Celignis Analysis Packages that determine Heating (Calorific) Value

Request a QuoteHeating (Calorific) Value

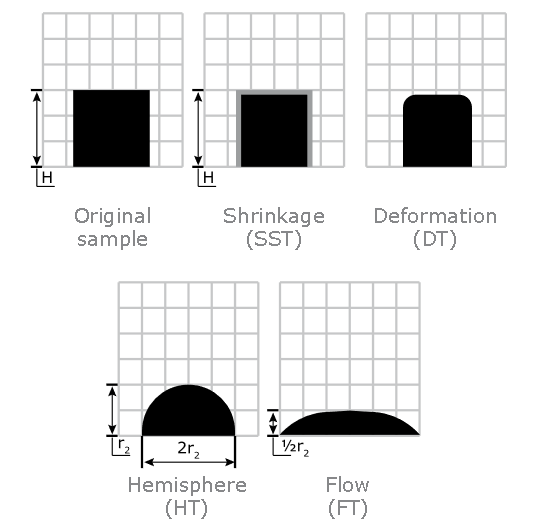

Ash Melting Behaviour of Hydrolysis Residues

Ash Shrinkage Starting Temperature (SST) - This occurs when the area of the test piece of Hydrolysis Residues ash falls below 95% of the original test piece area.

Ash Deformation Temperature (DT) - The temperature at which the first signs of rounding of the edges of the test piece occurs due to melting.

Ash Hemisphere Temperature (HT) - When the test piece of Hydrolysis Residues ash forms a hemisphere (i.e. the height becomes equal to half the base diameter).

Ash Flow Temperature (FT) - The temperature at which the Hydrolysis Residues ash is spread out over the supporting tile in a layer, the height of which is half of the test piece at the hemisphere temperature.

Click here to see the Celignis Analysis Packages that determine Ash Melting Behaviour

Request a QuoteAsh Melting Behaviour

Major and Minor Elements in Hydrolysis Residues

We can also determine the levels of 13 different minor elements (such as arsenic, copper, and zinc) that may be present in Hydrolysis Residues.

Click here to see the Celignis Analysis Packages that determine Major and Minor Elements

Request a QuoteMajor and Minor Elements

Analysis of Hydrolysis Residues for Anaerobic Digestion

Biomethane potential (BMP) of Hydrolysis Residues

Click here to see the Celignis Analysis Packages that determine BMP

Request a QuoteBMP

Physical Properties of Hydrolysis Residues

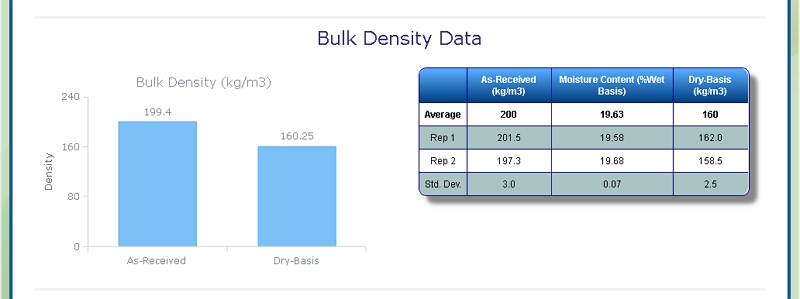

Bulk Density of Hydrolysis Residues

At Celignis we can determine the bulk density of biomass samples, including Hydrolysis Residues, according to ISO standard 17828 (2015). This method requires the biomass to be in an appropriate form (chips or powder) for density determination.

Click here to see the Celignis Analysis Packages that determine Bulk Density

Request a QuoteBulk Density

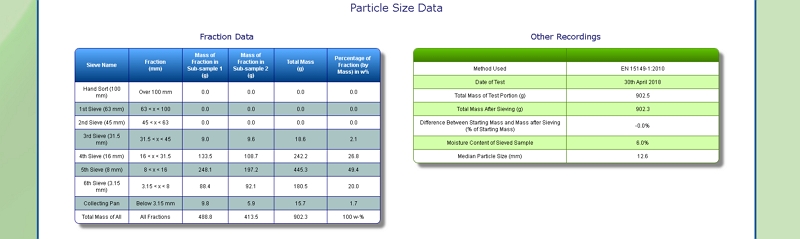

Particle Size of Hydrolysis Residues

Click here to see the Celignis Analysis Packages that determine Particle Size

Request a QuoteParticle Size

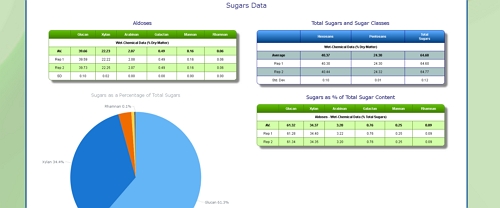

The processing of lignocellulosic materials in modern biorefineries will allow for the

production of transport fuels and platform chemicals that could replace petroleum-derived

products. However, there is a critical lack of relevant detailed compositional information

regarding feedstocks relevant to Ireland and Irish conditions. This research has involved the

collection, preparation, and the analysis, with a high level of precision and accuracy, of a

large number of biomass samples from the waste and agricultural sectors. Not all of the

waste materials analysed are considered suitable for biorefining; for example the total sugar

contents of spent mushroom composts are too low. However, the waste paper/cardboard

that is currently exported from Ireland has a chemical composition that could result in high

biorefinery yields and so could make a significant contribution to Irelandís biofuel demands. | ||