Analysis of Torrefied Biomass

Background on Torrefied Biomass

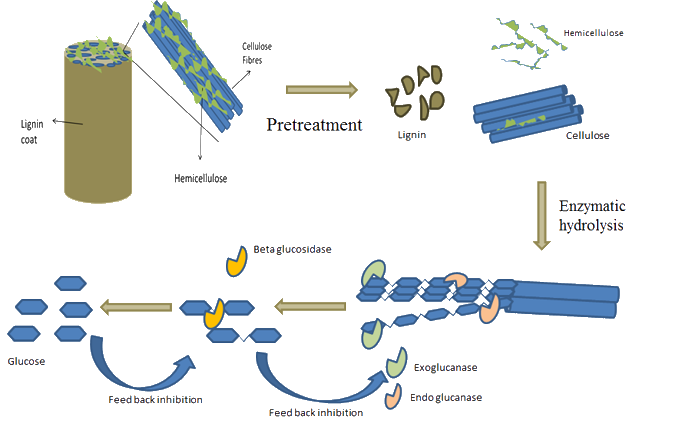

Torrefaction will remove moisture and volatiles from the biomass, with the types of constituents that are removed, and their extent of removal, being dependent on the temperature used and the duration of the process.

Analysis of Torrefied Biomass at Celignis

Celignis Analytical can determine the following properties of Torrefied Biomass samples:

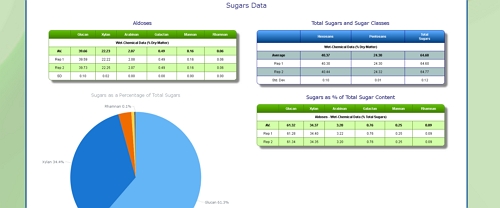

Lignocellulosic Properties of Torrefied Biomass

Cellulose Content of Torrefied Biomass

Click here to see the Celignis Analysis Packages that determine Cellulose Content

Request a QuoteCellulose Content

Hemicellulose Content of Torrefied Biomass

Click here to see the Celignis Analysis Packages that determine Hemicellulose Content

Request a QuoteHemicellulose Content

Lignin Content of Torrefied Biomass

Click here to see the Celignis Analysis Packages that determine Lignin Content

Request a QuoteLignin Content

Starch Content of Torrefied Biomass

Click here to see the Celignis Analysis Packages that determine Starch Content

Request a QuoteStarch Content

Uronic Acid Content of Torrefied Biomass

Click here to see the Celignis Analysis Packages that determine Uronic Acid Content

Request a QuoteUronic Acid Content

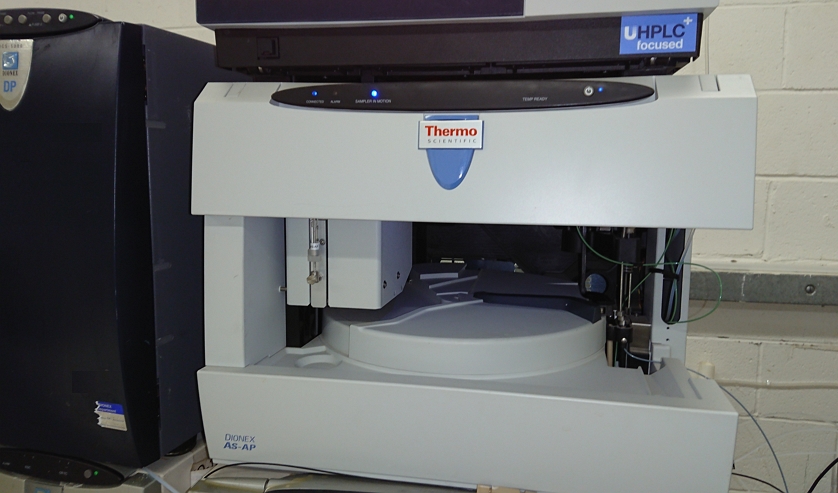

Enzymatic Hydrolysis of Torrefied Biomass

Click here to see the Celignis Analysis Packages that determine Enzymatic Hydrolysis

Request a QuoteEnzymatic Hydrolysis

Bioenergy Properties of Torrefied Biomass

Ash Content of Torrefied Biomass

Click here to see the Celignis Analysis Packages that determine Ash Content

Request a QuoteAsh Content

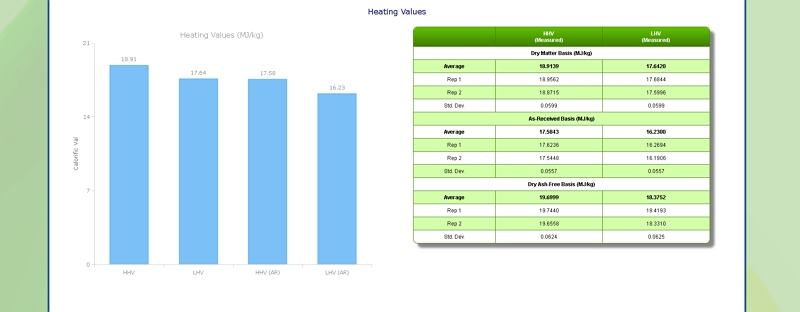

Heating (Calorific) Value of Torrefied Biomass

Click here to see the Celignis Analysis Packages that determine Heating (Calorific) Value

Request a QuoteHeating (Calorific) Value

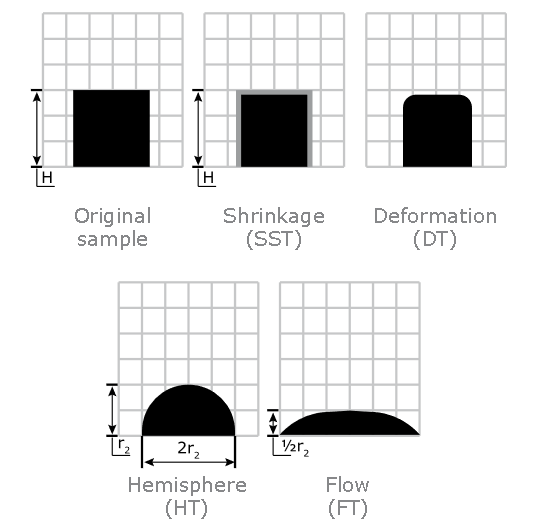

Ash Melting Behaviour of Torrefied Biomass

Ash Shrinkage Starting Temperature (SST) - This occurs when the area of the test piece of Torrefied Biomass ash falls below 95% of the original test piece area.

Ash Deformation Temperature (DT) - The temperature at which the first signs of rounding of the edges of the test piece occurs due to melting.

Ash Hemisphere Temperature (HT) - When the test piece of Torrefied Biomass ash forms a hemisphere (i.e. the height becomes equal to half the base diameter).

Ash Flow Temperature (FT) - The temperature at which the Torrefied Biomass ash is spread out over the supporting tile in a layer, the height of which is half of the test piece at the hemisphere temperature.

Click here to see the Celignis Analysis Packages that determine Ash Melting Behaviour

Request a QuoteAsh Melting Behaviour

Major and Minor Elements in Torrefied Biomass

We can also determine the levels of 13 different minor elements (such as arsenic, copper, and zinc) that may be present in Torrefied Biomass.

Click here to see the Celignis Analysis Packages that determine Major and Minor Elements

Request a QuoteMajor and Minor Elements

Analysis of Torrefied Biomass for Anaerobic Digestion

Biomethane potential (BMP) of Torrefied Biomass

Click here to see the Celignis Analysis Packages that determine BMP

Request a QuoteBMP

Physical Properties of Torrefied Biomass

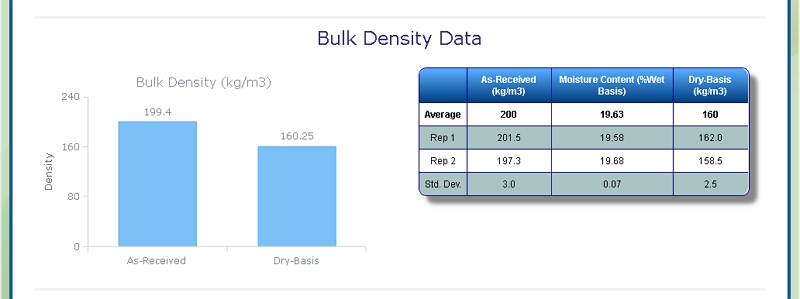

Bulk Density of Torrefied Biomass

At Celignis we can determine the bulk density of biomass samples, including Torrefied Biomass, according to ISO standard 17828 (2015). This method requires the biomass to be in an appropriate form (chips or powder) for density determination.

Click here to see the Celignis Analysis Packages that determine Bulk Density

Request a QuoteBulk Density

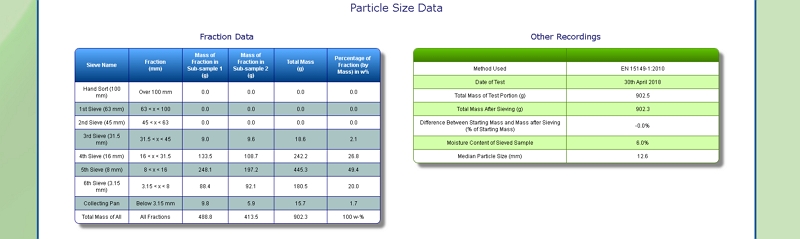

Particle Size of Torrefied Biomass

Click here to see the Celignis Analysis Packages that determine Particle Size

Request a QuoteParticle Size