AD Process Optimisations

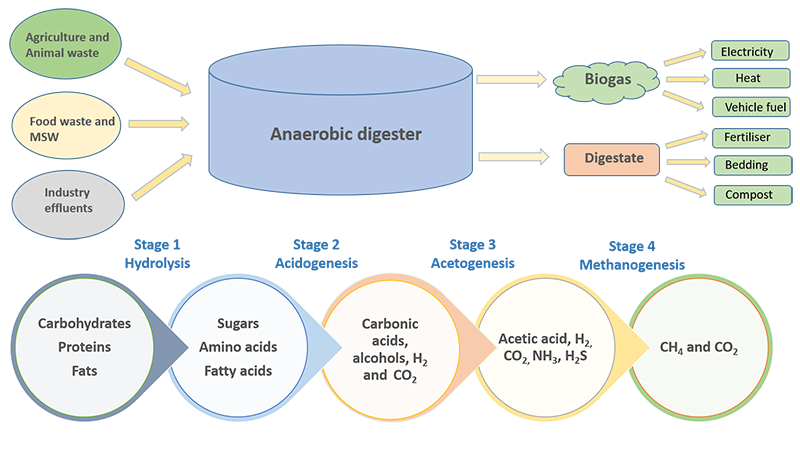

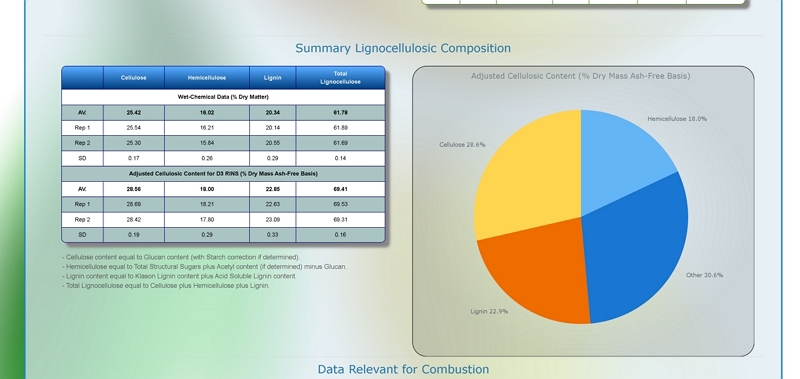

- The feedstock(s) used and their composition.

- Whether multiple feedstocks (co-feeds) are used and, if so, in which proportions.

- The Organic Loading Rate (OLR), defined as the amount of organic matter that is fed to the reactor per unit time and per unit reactor volume.

- The Hydraulic Retention Time (HRT) and Solid Retention Time (SRT), defined as the average time periods over which the liquids and solids are retained in the digester.

- The viscosity of the feed and digestates and the strategies that can be employed to reduce the negative effects of high viscosity.

- Whether, and to what degree, nutrients and trace metals are supplemented to aid with digestion.

Furthermore, if these performance issues are not addressed, matters may continue to deteriate over time, increasing the risk of potentially catastrophic events, such as a digester crash.

Some of the process optimisations that Celignis personnel can undertake for AD projects are detailed below.

Co-digestion with nutrient and pH complimenting feedstocks can be one of the several ways to improve the process efficiency. However, the fine-tuning of the co-feed ratio of different feedstocks for co-digestion, organic loading rate, and hydraulic retention time optimisation will be dependent on the particular feedstocks being considered.

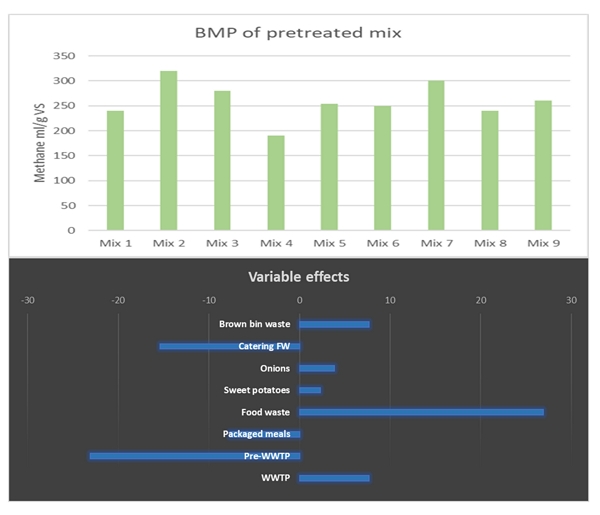

At Celignis we follow a scientifically-based Design of Experiments (DoE) protocol for undertaking optimisation trials for projects where a number of feedstocks are being considered. The criteria and boundaries for this DoE are formulated in close collaboration with our clients, considering factors such as the availability of each feedstock and whether certain feedsocks are preferred over others (due to higher gate fees, for example).

For example, in a scenario where we consider a number of feedstocks for a municipal-waste AD facility we can produce a Pareto chart showing the effect of each individual feedstock on the mix. In this chart the median line (“0”) indicates the baseline and the bars towards the positive axis indicate positive contribution and the bars towards the negative axis indicates negative contribution regarding BMP. The values indicate % variable effect.

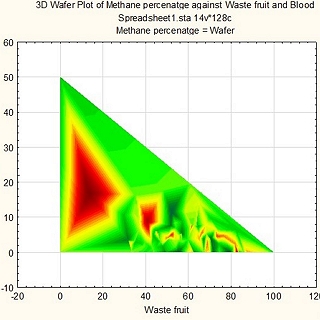

The figure presented here shows the percentage of methane in the biogas and how it varies according to the relative proportions by which fruit waste is co-fed with two different feedstocks. It can be seen that the optimum ratio varies substantially according to which co-feed feedstock is used.

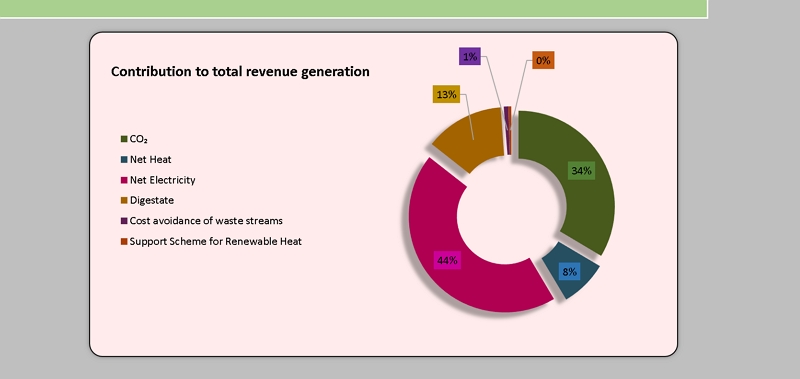

Such data can also feed into our Techno-economic Analyses (TEAs) of potential AD projects, whereby other factors (e.g. gate fees, predictability of feedstock supply) can factor into the metrics and inform what feedstock mix is ultimately proposed.

At Celignis we can undertake such experiments targetting improvements in biogas composition.

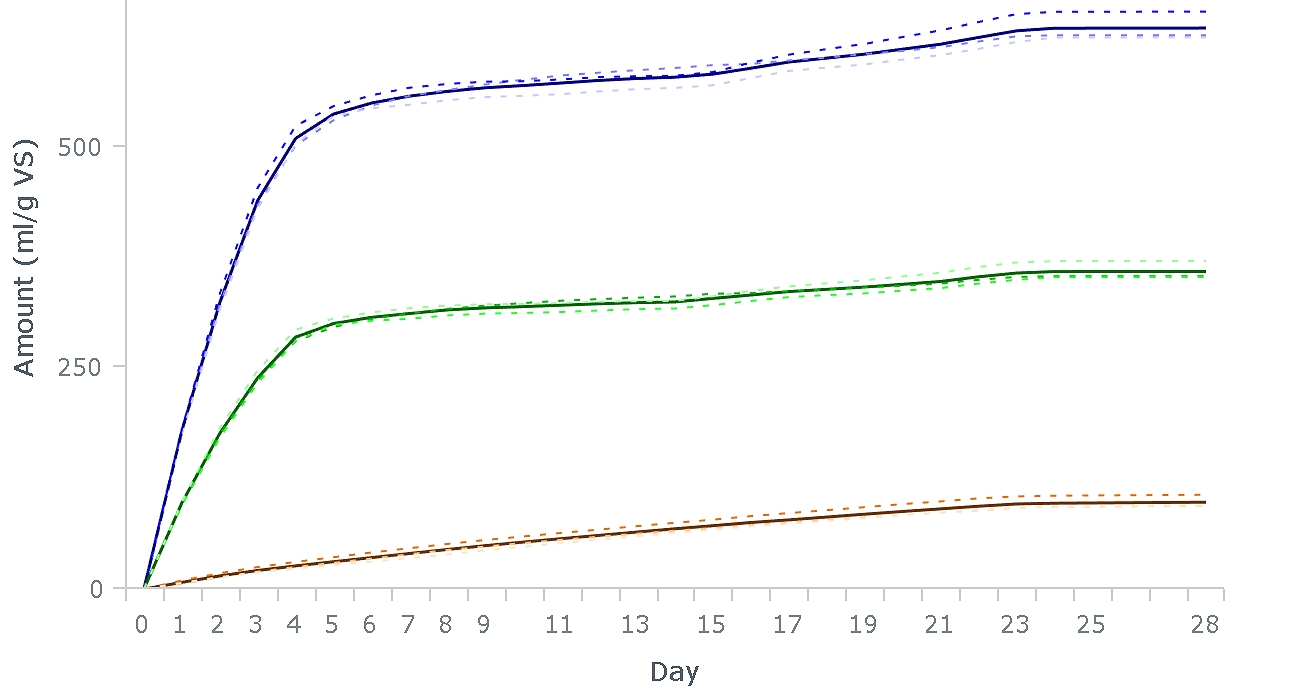

This strategy will then be tested, at various levels of bioaugmentation, in a series of appropriately-designed lab-scale experiments (undertaken in either batch (i.e. BMP tests) or continuous digestions).

The results of these experiments then allow us to provide recommendations on appropriate bioaugmentation strategies, considering other important factors (such as the cost of the extra microbes or enzymes).

Click here to read more on our specific microbial activity tests.

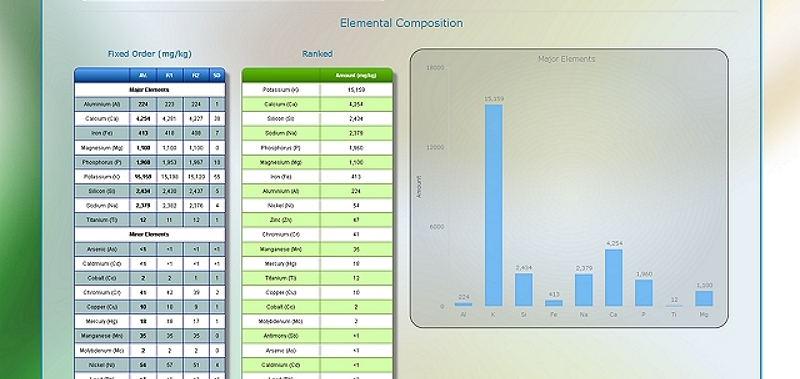

Each element has its role in microbial metabolism during anaerobic digestion and limitation of even a single element can cause process imbalances and decreases in process efficiency. Trace elements limitations can be mostly seen by VFAs accumulation and reduced biogas production.

Click here to read more about our services for testing nutrient supplementations in AD systems.

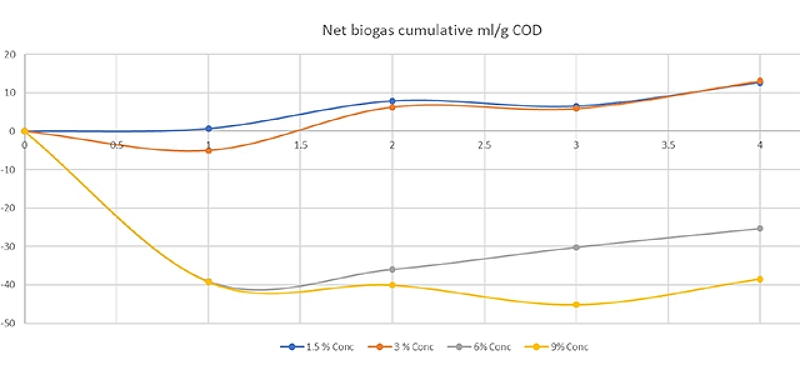

Accumulation of any of these components will lead to a signficant drop in the digester performance and may even lead to digester crash.

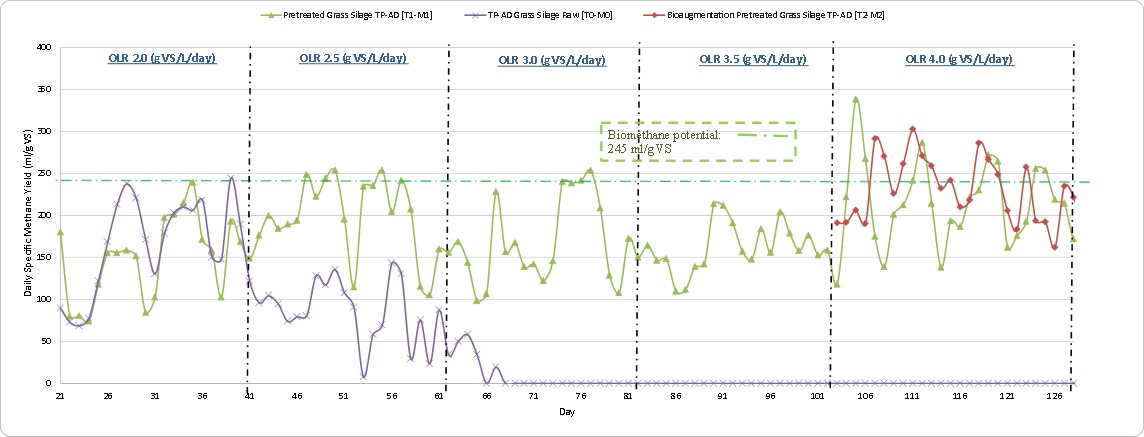

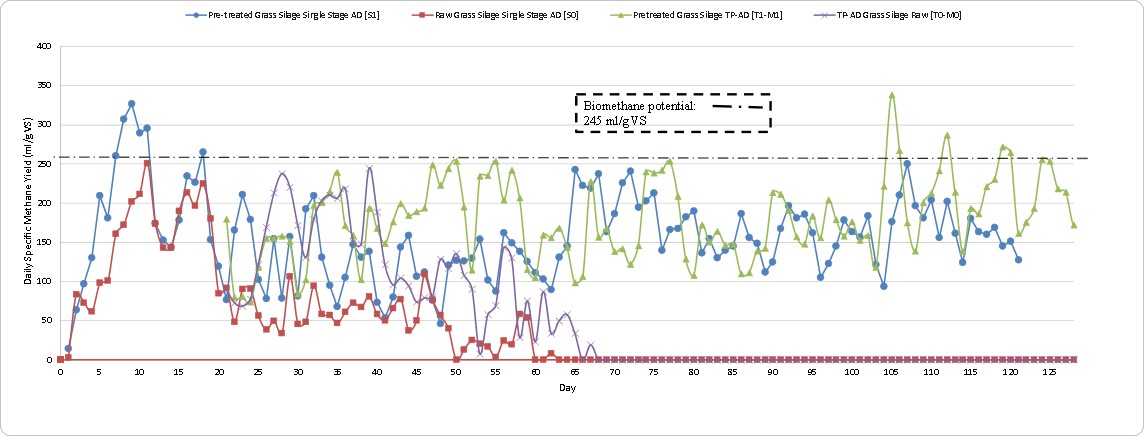

Where an increase in the OLR leads to accumulation of the above-mentioned compounds or a decrease in biogas yields we will consider strategies (e.g. nutrient supplementation, bioaugmentation) to obtain the maximum yields at maximum achievable OLR. In cases where these strategies are not successful we then return to the prior ORL level, where the efficiency of digestion was not impacted, and assign this as the practical maximum OLR for continuous operations. These lab-scale trials allow for OLR experimentation without running the risk of negatively affecting digester operations.

Additionally, continuous digestions allow us to see whether inoculum can adapt to novel feedstocks, or initially unfavourable process conditions, by implementing a structured adapataiton and start-up phase.

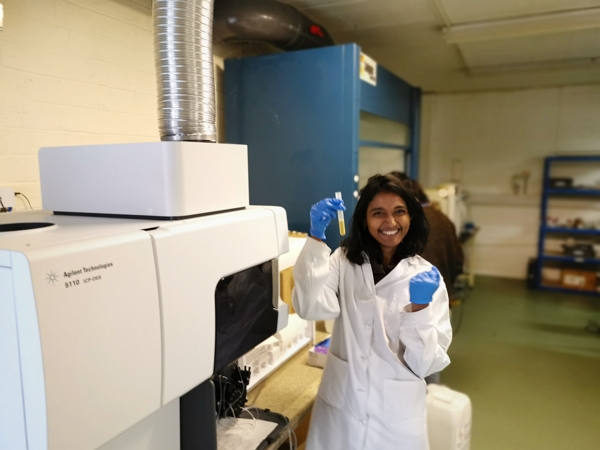

Lalitha Gottumukkala

Founder and Lead of Celignis AD, CIO of Celignis

PhD

Has a deep understanding of all biological and chemical aspects of anaerobic digestion. Has developed Celignis into a renowned provider of AD services to a global network of clients.

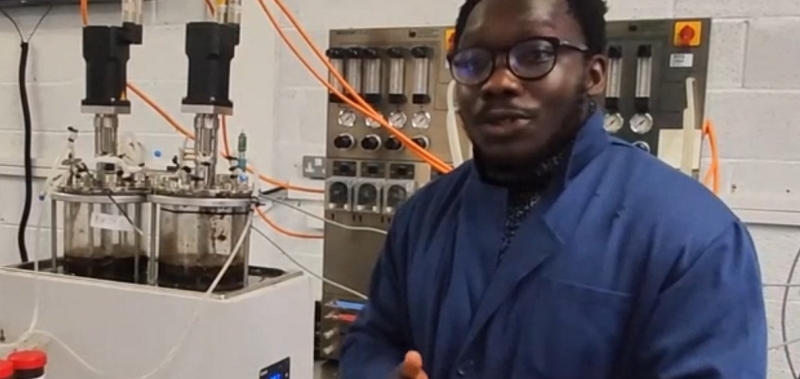

Kwame Donkor

AD Services Manager

BSc, MSc, Phd (yr 4)

His PhD focused on optimising AD conditions for Irish feedstocks such as grass. Kwame is now leading the Celignis AD team in the provision of analysis and bioprocess services.

Oscar Bedzo

Technoeconomic Analysis Lead

PhD

A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.

Global Recognition as AD/RNG Experts

Biomethane Potential

Continuous Digestions

Toxicity Assays

Feedstock Analysis

Biological Consultations

Specific Microbial Activity

Technoeconomic Analyses

Digestate Analysis

Project Development

Process Parameters

Nutrient Supplementations

Global warming and climate change are imminent threats to the future of humankind. A shift from the current reliance on fossil fuels to renewable energy is key to mitigating the impacts of climate change. Biological raw materials and residues can play a key role in this transition through technologies such as anaerobic digestion. However, biological raw materials must also meet other existing food, feed and material needs. Green biorefinery is an innovative concept in which green biomass, such as grass, is processed to obtain a variety of protein products, value-added co-products and renewable energy, helping to meet many needs from a single source. In this study, an analysis has been conducted to understand the renewable energy potential of green biorefinery by-products and residues, including grass whey, de-FOS whey and press cake. Using anaerobic digestion, the biogas and biomethane potential of these samples have been analyzed. An analysis of the fertiliser potential of the resulting digestate by-products has also been undertaken. All the feedstocks tested were found to be suitable for biogas production with grass whey, the most suitable candidate with a biogas and biomethane production yield of 895.8 and 544.6 L/kg VS, respectively, followed by de-FOS whey and press cake (597.4/520.3 L/kg VS and 510.7/300.3 L/kg VS, respectively). The results show considerable potential for utilizing biorefinery by-products as a source for renewable energy production, even after several value-added products have been co-produced. | ||

Anaerobic digestion (AD) is a bioprocess technology that integrates into circular economy systems, which produce renewable energy and biofertilizer whilst reducing greenhouse gas emissions. However, improvements in biogas production efficiency are needed in dealing with lignocellulosic biomass. The state-of-the-art of AD technology is discussed, with emphasis on feedstock digestibility and operational difficulty. Solutions to these challenges including for pre-treatment and bioaugmentation are reviewed. This article proposes an innovative integrated system combining alkali pre-treatment, temperature-phased AD and bioaugmentation techniques. The integrated system as modelled has a targeted potential to achieve a biodegradability index of 90% while increasing methane production by 47% compared to conventional AD. The methane productivity may also be improved by a target reduction in retention time from 30 to 20 days. This, if realized has the potential to lower energy production cost and the levelized cost of abatement to facilitate an increased resource of sustainable commercially viable biomethane. | ||

This study considered the possibility of reducing the environmental footprint of paper and pulp industry by producing bioenergy from paper sludge by using process wastewater instead of fresh water, and reclaiming water trapped in paper sludge. Experimental studies are conducted with streams from three different pulp and paper mills (virgin pulp mill (VP), corrugated recycling mill (CR), tissue printed recycling mill (TPR)) for sequential bioethanol and biogas production with simultaneous reclamation of water from paper sludge (PS). Total energy yields of 9215, 6387, 5278 MJ/tonne dry PS for VP, CR and TPR, respectively, were obtained for ethanol-biogas production. Virgin pulp paper sludge gave the highest yield for ethanol and biogas in stand-alone processes (275.4 kg and 67.7 kg per ton dry PS respectively) and also highest energy conversion efficiency (55%) in sequential process compared with CR and TPR. Energy and environmental case study conducted on virgin pulp mill has proven the possibility of using paper sludge bioenergy to reduce energy demand by 10%, while reclaiming 82% of the water from the PS, reducing greenhouse gas emissions (GHG) by 3 times and producing solids suitable for land spreading. | |

The paper and pulp industry is one of the major industries that generate large amount of solid waste with high moisture content. Numerous opportunities exist for valorisation of waste paper sludge, although this review focuses on primary sludge with high cellulose content. The most mature options for paper sludge valorisation are fermentation, anaerobic digestion and pyrolysis. In this review, biochemical and thermal processes are considered individually and also as integrated biorefinery. The objective of integrated biorefinery is to reduce or avoid paper sludge disposal by landfilling, water reclamation and value addition. Assessment of selected processes for biorefinery varies from a detailed analysis of a single process to high level optimisation and integration of the processes, which allow the initial assessment and comparison of technologies. This data can be used to provide key stakeholders with a roadmap of technologies that can generate economic benefits, and reduce carbon wastage and pollution load. | ||

Growth inhibition kinetics of a novel non-acetone forming butanol producer, Clostridium sporogenes BE01, was studied under varying concentrations of acetic and formic acids in rice straw hydrolysate medium. Both the organic acids were considered as inhibitors as they could inhibit the growth of the bacterium, and the inhibition constants were determined to be 1.6 and 0.76 g/L, respectively, for acetic acid and formic acid. Amberlite resins�XAD 4, XAD 7, XAD 16, and an anion exchange resin�Seralite 400 were tested for the efficient removal of these acidic inhibitors along with minimal adsorption of sugars and essential minerals present in the hydrolysate. Seralite 400 was an efficient adsorbent of acids, with minimal affinity towards minerals and sugars. Butanol production was evaluated to emphasize the effect of minerals loss and acids removal by the resins during detoxification. | |