Analysis of Xylose

Click here to place an order for determining Xylose.

Request a QuoteXylose Content

Analysis Packages for Xylose

Total Sugars, Glucose, Xylose, Mannose, Arabinose, Galactose, Rhamnose, Lignin (Klason), Lignin (Acid Soluble), Acid Insoluble Residue, Extractives (Ethanol-Soluble), Extractives (Water-Soluble), Extractives (Exhaustive - Water then Ethanol), Extractives (Water-Insoluble, Ethanol Soluble) , Ash, Ash (Acid Insoluble)

Total Sugars, Glucose, Xylose, Mannose, Arabinose, Galactose, Rhamnose, Lignin (Klason), Lignin (Klason - Protein Corrected), Lignin (Acid Soluble), Acid Insoluble Residue, Extractives (Ethanol-Soluble), Extractives (Water-Soluble), Extractives (Exhaustive - Water then Ethanol), Extractives (Water-Insoluble, Ethanol Soluble) , Ash, Ash (Acid Insoluble), Glucuronic Acid, Galacturonic Acid, 4-O-Methyl-D-Glucuronic Acid, Protein Content of Acid Insoluble Residue, Carbon Content of Acid Insoluble Residue, Hydrogen Content of Acid Insoluble Residue, Nitrogen Content of Acid Insoluble Residue, Sulphur Content of Acid Insoluble Residue, Xylitol, Sucrose, Fructose, Sorbitol, Trehalose

Total Sugars, Glucose, Xylose, Mannose, Arabinose, Galactose, Rhamnose, Lignin (Klason), Lignin (Acid Soluble), Carbon, Extractives (Ethanol-Soluble), Extractives (Water-Soluble), Extractives (Exhaustive - Water then Ethanol), Extractives (Water-Insoluble, Ethanol Soluble) , Ash, Ash (Acid Insoluble), Starch, Pectin, Glucuronic Acid, Galacturonic Acid, 4-O-Methyl-D-Glucuronic Acid

Analytical Procedure for Xylose

☑ Step 1: Acid Hydrolysis of the Sample

In the case where three different types of extracted material exist (water-extracted, ethanol-extracted, and water- then ethanol-extracted) then the sample that has undergone both water and ethanol extraction is typically used for acid hydrolysis, unless otherwise requested by the customer.

The following steps are involved in the acid hydrolysis of a sample.

1. The moisture content of the sample is determined, in duplicate.

2. Approximately 300 mg (with the exact weight noted) of the sample is added to a pressure tube.

3. 3.00 mL of 72% H2SO4 is added by means of an automatic titrator, the weight of the acid added is noted.

4. The sample is mixed thoroughly with the acid using a glass rod, care is taken that no sample stays adherent to the sides of the tube, but instead stays in contact with the acid.

5. The tube is transferred to a water bath that is maintained at 30 degrees celcius.

6. Steps 2-5 are repeated for the duplicate sample.

7. Every 10 minutes the glass rod for each pressure tube is stirred so that the acid reaches all parts of the sample and complete hydrolysis occurs. This is a crucial step.

8. Exactly one hour after it is placed in the water bath the pressure tube is removed and placed on a scales and 84 mL of water added (with the weight of the added water recorded). Any acid/sample on the rod is removed from the rod at this point using this water.

9. A lid is screwed on the tube and the tube is inverted several times to ensure thorough mixing of the acid.

10. Two sugar recovery solution (SRS) pressure tubes are prepared in order to monitor the sugar-loss associated with the second-stage-hydrolysis. This involves the following steps:

(a) 348 microlitres of 72% H2SO4 is added to a test tube containing a solution containing a known weight (approximately 10 g) of a sugar standard. This standard should be of a similar sugar composition to that expected of the samples being analysed. The acid and sugar solution are thoroughly mixed.

(b) The sugar-acid mixture is transferred to a pressure tube which is then sealed.

11. All SRS and sample pressure tubes are placed in an autoclave which is run at 121 degrees celcius for 60 minutes.

12. After the temperature in the autoclave drops to under 80C the tubes are removed and are left (closed) in the lab until they reach room temperature.

13. The hydrolysates are then filtered (using vacuum suction) through filter crucibles of known weight and the resulting filtrate is stored.

14. Any residual solids are washed out from the tube using deionised water until all the Acid Insoluble Residue resides on the filter crucible.

☑ Step 2: Hydrolysate Dilution and Storage

☑ Step 3: Chromatographic Analysis of the Hydrolysate

Equipment Used for Xylose Analysis

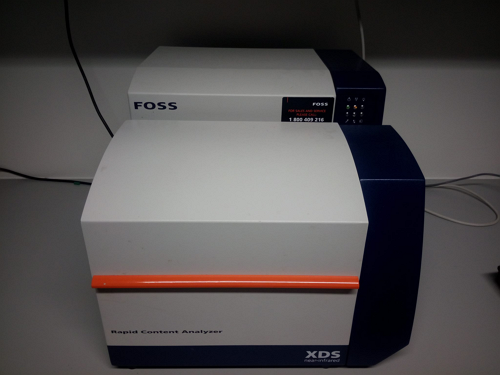

NIR Spectrophotometers

We have several FOSS XDS NIR devices. These have solid content modules, that can allow for samples of a heterogenous particle to be analysed, and liquid modules that allow liquids to be analysed via transmittance spectroscopy.

Ion Chromatography

A Dionex ICS-3000 system that is equipmed with electrochemical, conductivity, and ultraviolet-visible detectors.

Autoclave

An autoclave is used in the protocols for the determination of the lignin and structural sugars (cellulosic and hemicellulosic) contents of samples.

NIR Model

| Xylose Global 1 | |

| Min. Value (%) | 0.59 |

|---|---|

| Max. Value (%) | 27.59 |

| Calibration Samples | 450 |

| Validation Samples | 154 |

| R2 (Validation) | 0.9782 |

| RMSEP (%) | 1.1377 |

| Bias (%) | -0.0524 |

| SEP (%) | 1.1402 |

| RPD | 6.7727 |

| RER | 22.9952 |

Analytical data and quantitative near infrared (NIR) spectroscopy models for various lignocellulosic components (including Klason lignin and the constituent sugars glucose, xylose, mannose, arabinose, galactose, and rhamnose), ash, and ethanol-soluble extractives, were obtained for 53 samples of paper and cardboard. These samples were mostly the type of materials typically found in domestic wastes (e.g. newspapers, printing paper, glossy papers, food packaging). A number of the samples (48) were obtained by separating a sample, after milling, into two particle size fractions. It was found that the fractions containing the smaller particles typically had higher ash and Klason lignin contents and lower glucose and xylose contents that the larger particle size fractions. Nevertheless, all of the sample types had attractive total sugars contents (>50%) indicating that these could be suitable feedstocks for the production of biofuels and chemicals in hydrolysis-based biorefining technologies. NIR models of a high predictive accuracy (R2 of > 0.9 for the independent validation set) were obtained for total sugars, glucose, xylose, Klason lignin, and ash and with values for the Root Mean Square Error of Prediction (RMSEP) of 2.36%, 2.64%, 0.56%, 1.98%, and 4.87%, respectively. Good NIR models (R2 of > 0.8) were also obtained for mannose, arabinose, and galactose. These results suggest that NIR is a suitable method for the rapid, low-cost, analysis of the major lignocellulosic components of waste paper/cardboard samples. | |

The paper and pulp industry is one of the major industries that generate large amount of solid waste with high moisture content. Numerous opportunities exist for valorisation of waste paper sludge, although this review focuses on primary sludge with high cellulose content. The most mature options for paper sludge valorisation are fermentation, anaerobic digestion and pyrolysis. In this review, biochemical and thermal processes are considered individually and also as integrated biorefinery. The objective of integrated biorefinery is to reduce or avoid paper sludge disposal by landfilling, water reclamation and value addition. Assessment of selected processes for biorefinery varies from a detailed analysis of a single process to high level optimisation and integration of the processes, which allow the initial assessment and comparison of technologies. This data can be used to provide key stakeholders with a roadmap of technologies that can generate economic benefits, and reduce carbon wastage and pollution load. | ||

Paper sludge (PS) from the paper and pulp industry consists primarily of cellulose and ash and has significant potential for ethanol production. Thirty-seven PS samples from 11 South African paper and pulp mills exhibited large variation in chemical composition and resulting ethanol production. Simultaneous saccharification and fermentation (SSF) of PS in fed-batch culture was investigated at high solid loadings and low enzyme dosages. Water holding capacity and viscosity of the PS influenced ethanol production at elevated solid loadings of PS. High viscosity of PS from virgin pulp mills restricted the solid loading to 18% (w/w) at an enzyme dosage of 20 FPU/gram dry PS (gdPS), whereas an optimal solid loading of 27% (w/w) was achieved with corrugated recycle mill PS at 11 FPU/gdPS. Ethanol concentration and yield of virgin pulp and corrugated recycle PS were 34.2 g/L at 66.9% and 45.5 g/L at 78.2%, respectively. | |

Paper sludge samples collected from recycling mills exhibited high ash content in the range of 54.59%–65.50% and glucose concentrations between 21.97% and 31.11%. Washing the sludge reduced the total ash content to between 10.7% and 19.31% and increased the concentration of glucose, xylose and lignin. Samples were screened for ethanol production and fed-batch simultaneous saccharification and fermentation (SSF) was optimised for the washed samples that resulted in highest and lowest ethanol concentrations. Maximum ethanol concentrations of 57.31 g/L and 47.72 g/L (94.07% and 85.34% of the maximum theoretical yield, respectively) was predicted for high and low fermentative potential samples, respectively, and was experimentally achieved with 1% deviation. A generic set of process conditions were established for the conversion of high ash-containing paper sludge to ethanol. Techno-economic analysis based on three different revenue scenarios, together with Monte Carlo analysis revealed 95% probability of achieving IRR values in excess of 25% at a paper sludge feed rate of 15 t/d. Feed rates of 30 t/d and 50 t/d exhibited a cumulative probability of 100%. This study presents the technical feasibility and economic viability of paper mills expansion towards bioethanol production from paper sludge. | |

Next-generation biofuels from renewable sources have gained interest among research investigators, industrialists, and governments due to major concerns on the volatility of oil prices, climate change, and depletion of oil reserves. Biobutanol has drawn signicant attention as an alternative transportation fuel due to its superior fuel properties over ethanol. e advantages of butanol are its high energy content, better blending with gasoline, less hydroscopic nature, lower volatility, direct use in convention engines, low corrosiveness, etc. Butanol production through (acetone, butanol, and ethanol) ABE fermentation is a well-established process, but it has several drawbacks like feedstock cost, strain degeneration, product toxicity, and low product concentrations. Lignocellulosic biomass is considered as the most abundant, renewable, low-cost feedstock for biofuels. Production of butanol from lignocellulosic biomass is more complicated due to the recalcitrance of feedstock and inhibitors generated during the pretreatment and hydrolysis process. Advanced fermentation and product recovery techniques are being researched to make biobutanol industrially viable. | |

Analytical data and quantitative near infrared (NIR) spectroscopy models for various lignocellulosic components (including Klason lignin and the constituent sugars glucose, xylose, mannose, arabinose, galactose, and rhamnose), moisture, and ash were obtained for 53 peat samples. These included samples with high, medium, and low degrees of humification. Klason lignin was the main constituent and was greatest in the samples classified as being highly humified, with structural sugars the lowest in this class. The total sugars contents of all samples were considered to be insufficient to allow for their use in biorefining hydrolysis processes for the production of chemicals and biofuels. NIR models were developed for spectral datasets obtained from the samples in their unprocessed (wet), dry and unground, and dry and ground states. Typically the most accurate models were based on the spectra of dry and ground samples. However the NIR models for the wet samples still offered reasonable predictive capabilities. All models were suitable at least for sample screening, with the models for total sugars, glucose, xylose, galactose, and moisture suitable for quantitative analyses. | |

Clostridium sporogenes BE01, a non-acetone forming butanol producer, can produce hydrogen and volatile fatty acids (VFAs) during butanol fermentation from rice straw hydrolysate. Bio-electrochemical analysis revealed the changes that occurred in the redox microenvironment and electron transport mediators during fermentation at different pH and CaCO3 concentrations. CaCO3 played a very important role in enhancing the production of hydrogen, volatile fatty acids and solvents by stimulating the changes in the electron transport system. The electron transport system mediated by NAD/NADH, flavins, Fe–S clusters, protein bound FAD, and cytochrome complex in C. sporogenes BE01 was analysed by cyclic voltammetry (CV). Electrokinetic analysis revealed that the favorability for redox reactions increased with an increase in pH, and the polarization resistance reduced significantly with CaCO3 supplementation. | |

Growth inhibition kinetics of a novel non-acetone forming butanol producer, Clostridium sporogenes BE01, was studied under varying concentrations of acetic and formic acids in rice straw hydrolysate medium. Both the organic acids were considered as inhibitors as they could inhibit the growth of the bacterium, and the inhibition constants were determined to be 1.6 and 0.76 g/L, respectively, for acetic acid and formic acid. Amberlite resins—XAD 4, XAD 7, XAD 16, and an anion exchange resin—Seralite 400 were tested for the efficient removal of these acidic inhibitors along with minimal adsorption of sugars and essential minerals present in the hydrolysate. Seralite 400 was an efficient adsorbent of acids, with minimal affinity towards minerals and sugars. Butanol production was evaluated to emphasize the effect of minerals loss and acids removal by the resins during detoxification. | |

Miscanthus plants were sampled from several plantations in Ireland over the harvest window (October-April). These were separated into their anatomical components and the loss of leaves monitored. Three distinct phases were apparent: there was minimal loss in the "Early" (October to early December) and "Late" (March and April) phases, and rapid leaf loss in the interim period. Samples were analysed for constituents relevant to biorefining. Changes in whole-plant composition included increases in glucose and Klason lignin contents and decreases in ash and arabinose contents. These changes arose mostly from the loss of leaves, but there were some changes over time within the harvestable plant components. Although leaves yield less biofuel than stems, the added biomass provided by an early harvest (31.9-38.4%) meant that per hectare biofuel yields were significantly greater (up to 29.3%) than in a late harvest. These yields greatly exceed those from first generation feedstocks. | |

Biobutanol from lignocellulosic biomass has gained much attention due to several advantages over bioethanol. Though microbial production of butanol through ABE fermentation is an established technology, the use of lignocellulosic biomass as feedstock presents several challenges. In the present study, biobutanol production from enzymatic hydrolysate of acid pretreated rice straw was evaluated using Clostridium sporogenes BE01. This strain gave a butanol yield of 3.43 g/l and a total solvent yield of 5.32 g/l in rice straw hydrolysate supplemented with calcium carbonate and yeast extract. Hydrolysate was analyzed for the level of inhibitors such as acetic acid, formic acid and furfurals which affect the growth of the organism and in turn ABE fermentation. Methods for preconditioning the hydrolysate to remove toxic end products were done so as to improve the fermentation efficiency. Conditions of ABE fermentation were fine tuned resulting in an enhanced biobutanol reaching 5.52 g/l. | |

Miscanthus samples were scanned over the visible and near infrared wavelengths at several stages of processing (wet-chopped, air-dried, dried and ground, and dried and sieved). Models were developed to predict lignocellulosic and elemental constituents based on these spectra. The dry and sieved scans gave the most accurate models; however the wet-chopped models for glucose, xylose, and Klason lignin provided excellent accuracies with root mean square error of predictions of 1.27%, 0.54%, and 0.93%, respectively. These models can be suitable for most applications. The wet models for arabinose, Klason lignin, acid soluble lignin, ash, extractives, rhamnose, acid insoluble residue, and nitrogen tended to have lower R(2) values (0.80+) for the validation sets and the wet models for galactose, mannose, and acid insoluble ash were less accurate, only having value for rough sample screening. This research shows the potential for online analysis at biorefineries for the major lignocellulosic constituents of interest. | |

The processing of lignocellulosic materials in modern biorefineries will allow for the

production of transport fuels and platform chemicals that could replace petroleum-derived

products. However, there is a critical lack of relevant detailed compositional information

regarding feedstocks relevant to Ireland and Irish conditions. This research has involved the

collection, preparation, and the analysis, with a high level of precision and accuracy, of a

large number of biomass samples from the waste and agricultural sectors. Not all of the

waste materials analysed are considered suitable for biorefining; for example the total sugar

contents of spent mushroom composts are too low. However, the waste paper/cardboard

that is currently exported from Ireland has a chemical composition that could result in high

biorefinery yields and so could make a significant contribution to Ireland’s biofuel demands. | ||

ABE (Acetone-Butanol-Ethanol) fermentations were next only to ethanol fermentations and used to be a major industry until 1960s. Later, biological route for butanol production lost its importance owing to competition from petrochemical route, and today there is a renewed interest in ABE fermentation due to increased concerns over petroleum depletion and the increased pollution due to burning of petroleum fuels. Though the ABE fermentation process used to be operational decades back, the same technologies are not applicable today due to the lack of cost effectiveness and the nonavailability of conventional raw materials. The most feasible feedstock for butanol seems to be lignocellulose, but the problems plaguing bioethanol are also applicable for biobutanol. However, the future for biobutanol seemsbright since the Clostridia that produce ABE are capable of utilizing a range of carbon sources for growth and solvent production and also are not inhibited by the sugar degradation products generated during biomass pretreatment are being developed. Meanwhile, in the short term, advanced fermentation technologies are being developed by the expert groups which tackle problems such as low cell density, viability, and solvent sensitivity by modulations in the methods of carbon feeding, mode of culture, and in situ removal and recovery of solvents. These efforts may be developed into commercially viable technologies. | |

Rice straw is an attractive lignocellulosic material for bioethanol production since it is one of the most abundant renewable resources. It has several characteristics, such as high cellulose and hemicelluloses content that can be readily hydrolyzed into fermentable sugars. But there occur several challenges and limitations in the process of converting rice straw to ethanol. The presence of high ash and silica content in rice straw makes it an inferior feedstock for ethanol production. One of the major challenges in developing technology for bioethanol production from rice straw is selection of an appropriate pretreatment technique. The choice of pretreatment methods plays an important role to increase the efficiency of enzymatic saccharification thereby making the whole process economically viable. The present review discusses the available technologies for bioethanol production using rice straw. | |

Biomass feedstock having less competition with food crops are desirable for bio-ethanol production and such resources may not be localized geographically. A distributed production strategy is therefore more suitable for feedstock like water hyacinth with a decentralized availability. In this study, we have demonstrated the suitability of this feedstock for production of fermentable sugars using cellulases produced on site. Testing of acid and alkali pretreatment methods indicated that alkali pretreatment was more efficient in making the sample susceptible to enzyme hydrolysis. Cellulase and ?-glucosidase loading and the effect of surfactants were studied and optimized to improve saccharification. Redesigning of enzyme blends resulted in an improvement of saccharification from 57% to 71%. A crude trial on fermentation of the enzymatic hydrolysate using the common baker’s yeast Saccharomyces cerevisiae yielded an ethanol concentration of 4.4 g/L. | |