Analysis of Combustible Fuel Parameters of Biochar

Biochar can potentially be used in a wide variety of applications, including: as a soil amendment, a component of biobased materials, and in pollution remediation.

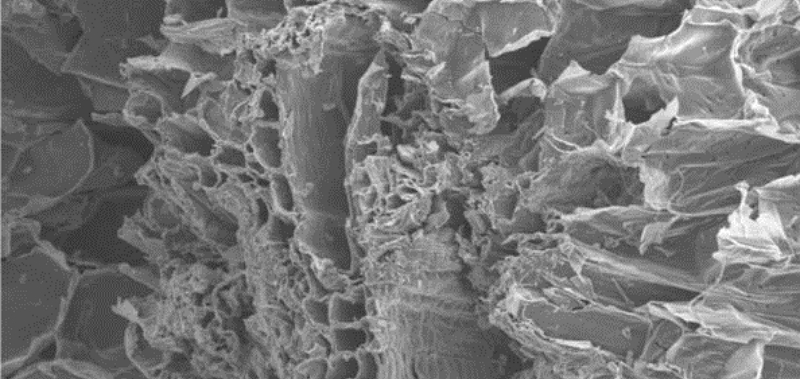

Biochar also often has several properties that make suitable as a fuel source. For example, it typically has higher carbon contents and hydrogen contents and lower oxygen contents than the starting feedstock, which result in it having a greater calorific value. Biochar can also usually be compressed at higher densities than the starting feedstock which, coupled with the increased carbon content and calorific values, leads to a fuel with a significantly greater energy density.

However, it is important to note that not all types of biomass are appropriate for producing biochar suitable for us as a combustible fuel. Factors such as the chemical composition and the content and composition of ash can all affect the properties of the resulting biochar. Additionally, the pyrolysis process itself can impact the quality of the biochar, so careful control of temperature, duration, and other factors is necessary to produce biochar with optimal fuel properties.

Typically carbon, hydrogen, nitrogen, and sulphur can be determined in the same analytical method and the oxygen content can then be calculated as the remaining mass after the ash content has been considered.

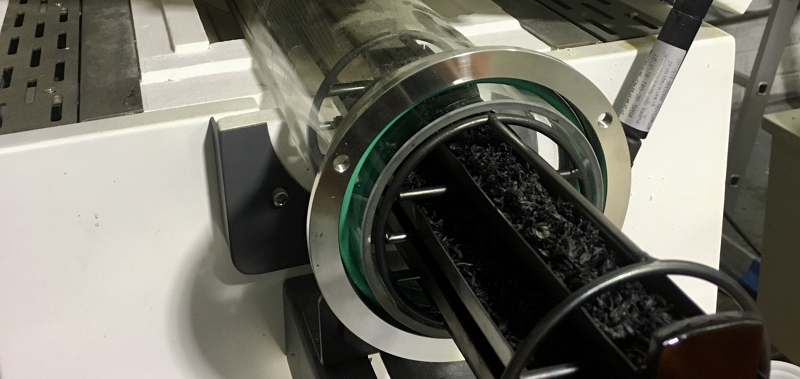

We use an Elementar MACRO Cube unit for the ultimate analysis of samples. It allows for large sample sizes (e.g. around 40mg) to be used than many other elemental analysers, allowing us to improve the precision in the analysis of biochar samples.

Volatile Matter, Fixed Carbon, Moisture, Ash, Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Gross Calorific Value, Net Calorific Value, Chlorine, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing), Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium

Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Specific Surface Area (Nitrogen Gas Adsorption), Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Differentiation Between Inorganic Carbon and Organic Carbon in Biochar

It is important to differentiate between the two forms of carbon in biochar given that organic carbon is preferred when considering biochar as a tool for cabron sequestration, plant growth promotion, and combustion.

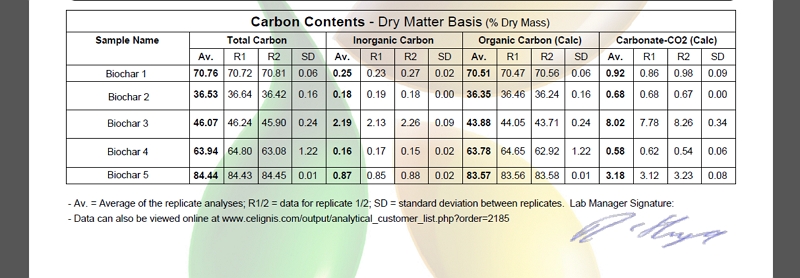

The Dumas analysis of a biochar sample, as described in the section above, will provide data on total carbon content of the biochar. However, we can also undertake a carbon analysis of the biochar ash in order to determine the inorganic carbon content. This can then be subtracted from the total carbon content in order to determine the organic carbon content of the biochar sample.

At Celignis we check as to whether the ratio for biochar samples is above or below this threshold value and provide the results in a PASS/FAIL table included as part of our pdf reports. An example table is provided below.

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Specific Surface Area (Nitrogen Gas Adsorption), Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Analysis of the Content and Composition of Ash in Biochar

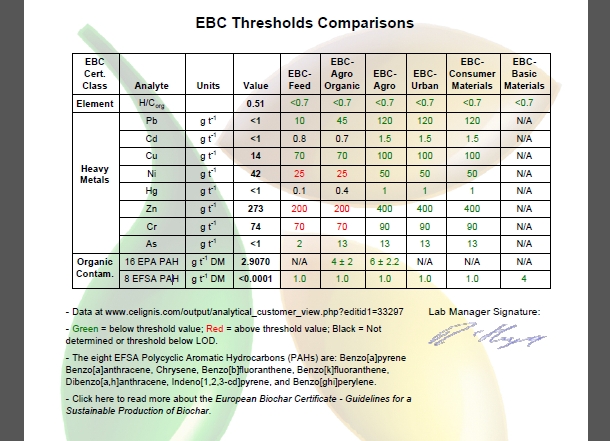

The major cations present in biochar ashes are Calcium, Potassium and Magnesium. Other elements such as Manganese, Sulphur and Phosphorus are present in minor amounts. Trace constituents (such as Al, Fe, Zn, Cu, Ti, Pb, Ni, V, Co, Ag and Mo) are also found in many substrates. The anions that are usually present are Chloride, Carbonate, Sulphate and Silicate.

With biochars produced from waste feedstocks (municipal solid wastes in particular), ashes are often more abundant and more diverse.

Volatile Matter, Fixed Carbon, Moisture, Ash, Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Gross Calorific Value, Net Calorific Value, Chlorine, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing), Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium

Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Specific Surface Area (Nitrogen Gas Adsorption), Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

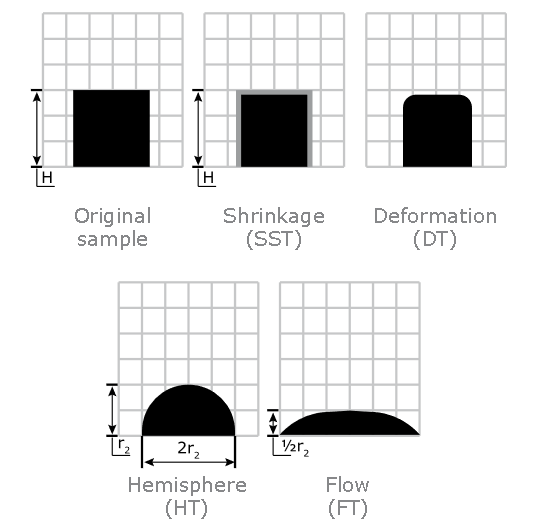

Ash Melting Behaviour of Biochar

Ash Shrinkage Starting Temperature (SST) - This occurs when the area of the test piece of biomass ash falls below 95% of the original test piece area.

Ash Deformation Temperature (DT) - The temperature at which the first signs of rounding of the edges of the test piece occurs due to melting.

Ash Hemisphere Temperature (HT) - When the test piece of biomass ash forms a hemisphere (i.e. the height becomes equal to half the base diameter).

Ash Flow Temperature (FT) - The temperature at which the biomass ash is spread out over the supporting tile in a layer, the height of which is half of the test piece at the hemisphere temperature.

Volatile Matter, Fixed Carbon, Moisture, Ash, Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Gross Calorific Value, Net Calorific Value, Chlorine, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing), Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium

Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Specific Surface Area (Nitrogen Gas Adsorption), Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

There are several units of measurement. The caloric, or higher heating value (HHV), is independent of moisture content and reliant on the chemical composition of the material. A linear relationship exists between the heat of combustion and the carbon content of the substrate while oxygen, nitrogen and inorganic elements tend to reduce the value.

The Lower Heating Value (LHV), or effective heating value, is perhaps more relevant than the HHV in practical operations. It considers not only the energy required to vaporise the moisture of the biochar but also that necessary to vaporise the water generated when the hydrogen and oxygen elements of the biochar combine. Hydrogen content then becomes a reducing factor in the heating value.

The heating value can be reported on a dry or wet basis. The wet-basis value considers the moisture content of the biomass and reduces the heating value to incorporate the latent heat of condensation.

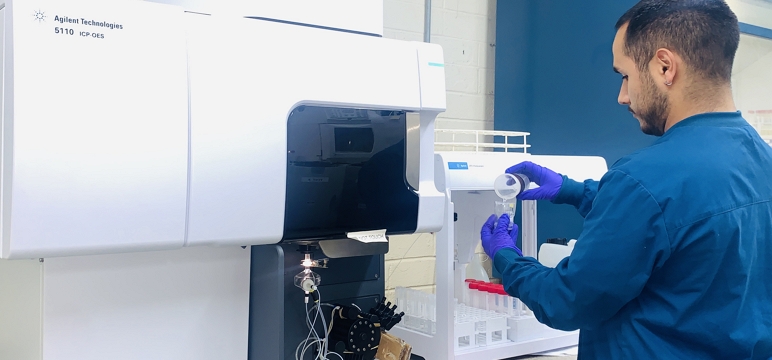

At Celignis we use a Parr 6200 bomb calorimeter to directly determine the gross calorific value (higher heating value) of samples. The data from ultimate analysis are then used to calculate the net calorific value (lower heating value).

Volatile Matter, Fixed Carbon, Moisture, Ash, Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Gross Calorific Value, Net Calorific Value, Chlorine, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing), Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium

Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Specific Surface Area (Nitrogen Gas Adsorption), Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Volatile Matter and Fixed Carbon Contents of Biochar

Fixed carbon is generally considered to be a desirable property of biochar, as it represents a potentially stable form of carbon that can be used for carbon sequestration or soil improvement. The volatile matter content of biochar can affect its physical properties, such as its porosity and density, as well as its chemical properties, such as its ability to release nutrients or affect soil pH. Generally, biochar with a lower volatile matter content is preferred for applications such as soil amendment, as it is less likely to release harmful compounds or affect soil fertility.

In general, fuels with a higher fixed carbon content and a lower volatile matter content are preferred for combustion applications, as they tend to be more efficient and produce fewer emissions. However, the optimal balance between fixed carbon and volatile matter content can vary depending on the specific application and combustion technology being used.

Correspondingly, the fixed carbon content of biochar is typically much higher than that of the starting feedstock material. This is because during the pyrolysis process, some of the carbon in the feedstock material is converted into a stable form that is resistant to decomposition. This stable carbon makes up the fixed carbon content of the biochar.

Below are listed the Celignis analysis packages that determine the fixed carbon and volatile matter contents of biochar.

Volatile Matter, Fixed Carbon, Moisture, Ash, Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Gross Calorific Value, Net Calorific Value, Chlorine, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing), Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium

Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Aluminium, Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Thernogram - Under Nitrogen, Thermogram - Under Air, Moisture, Inherent Moisture, Ash Content (815C), Carbon, Hydrogen, Nitrogen, Sulphur, Oxygen, Organic Carbon, Inorganic Carbon, Chlorine, Volatile Matter, Fixed Carbon, Specific Surface Area (Nitrogen Gas Adsorption), Calcium, Iron, Magnesium, Phosphorus, Potassium, Silicon, Sodium, Titanium, Gross Calorific Value, Net Calorific Value, Ash Shrinkage Starting Temperature (Reducing), Ash Deformation Temperature (Reducing), Ash Hemisphere Temperature (Reducing), Ash Flow Temperature (Reducing)

Sajna KV

Bioanalysis Developer

PhD

Our Biomass Detective! Designs, tests, optimizes and validates robust analytical methods for properties of relevance to the various biochar market applications.

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.