Analysis of Sugarcane Bagasse

Background on Sugarcane Bagasse

The first use for this resource is as a heat and steam provider to satisfy the energy needs of the sugar production or fermentation processes. It has been estimated that a minimum of 50% of the bagasse is required for this. In many cases the surplus bagasse represents a problematic waste that could lead to safety issues (e.g. spontaneous combustion) if stored for a long period of time. For that reason some mills deliberately burn the bagasse at a low efficiency so that more of it is consumed for energy production.

It has been estimated that the use of sugarcane bagasse in boilers could be decreased by up to 36% if more efficient combustion schemes are employed, potentially offering an increased supply of biomass for biorefining purposes. Indeed, there has been a significant amount of research into utilising sugarcane bagasse in biorefining technologies that may produce saleable chemicals from the polysaccharides or produce bio-oils via the pyrolysis of this residue.

The sugarcane harvest residue that is left on the field, often referred to as sugarcane trash, is also a potential biomass resource. This feedstock comprises the leaves and the tops of the plant; fractions with insufficient sucrose content to warrant their transportation to the mill. It has been estimated that, for each tonne of harvested cane, 140 kg of trash will exist. This is the case only where the cane is mechanically harvested (which involves the trash being blown back onto the field by the harvester). Manual practices require the crop to be burnt prior to the chopping of the stems by workers. This will burn the leaves of the crop but not damage the stems and roots. Manual harvesting occurs only in developing nations and is being gradually phased out. For example, the Brazilian government has targeted 2020 as a date when all harvesting will be mechanical.

Celignis founder Daniel Hayes has extensive experience in the chemical/infrared analysis of sugarcane bagasse and sugarcane trash. As part of the DIBANET project, he spent approximately 2 years working in Brazil where he was responsible for the analysis of Latin American biomass feedstocks and in the development of near infrared models for these. This work included the installation of an online near-infrared device at a sugar-mill. Daniel Hayes also spent time working in Australia where he undertook chemical and near-infrared analysis of sugarcane bagasse samples.

Analysis of Sugarcane Bagasse at Celignis

Celignis Analytical can determine the following properties of Sugarcane Bagasse samples:

Lignocellulosic Properties of Sugarcane Bagasse

Cellulose Content of Sugarcane Bagasse

Click here to see the Celignis Analysis Packages that determine Cellulose Content

Request a QuoteCellulose Content

Hemicellulose Content of Sugarcane Bagasse

Click here to see the Celignis Analysis Packages that determine Hemicellulose Content

Request a QuoteHemicellulose Content

Lignin Content of Sugarcane Bagasse

Click here to see the Celignis Analysis Packages that determine Lignin Content

Request a QuoteLignin Content

Starch Content of Sugarcane Bagasse

Click here to see the Celignis Analysis Packages that determine Starch Content

Request a QuoteStarch Content

Uronic Acid Content of Sugarcane Bagasse

Click here to see the Celignis Analysis Packages that determine Uronic Acid Content

Request a QuoteUronic Acid Content

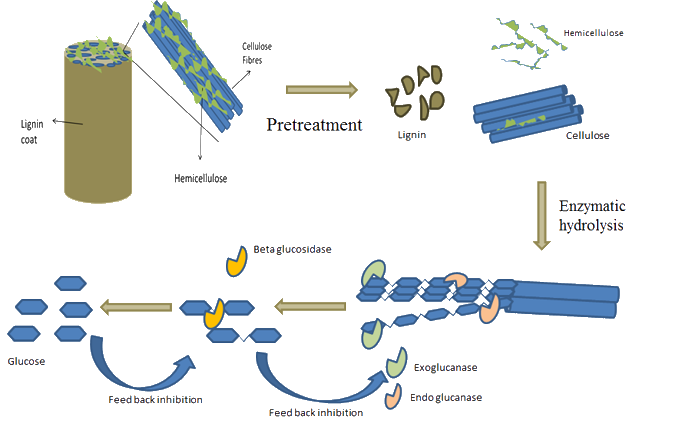

Enzymatic Hydrolysis of Sugarcane Bagasse

Click here to see the Celignis Analysis Packages that determine Enzymatic Hydrolysis

Request a QuoteEnzymatic Hydrolysis

Bioenergy Properties of Sugarcane Bagasse

Ash Content of Sugarcane Bagasse

Click here to see the Celignis Analysis Packages that determine Ash Content

Request a QuoteAsh Content

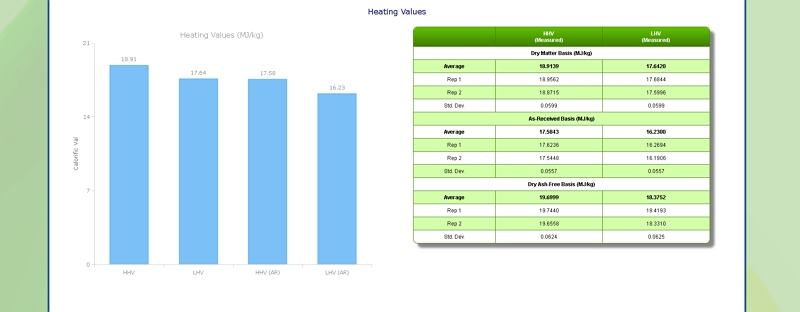

Heating (Calorific) Value of Sugarcane Bagasse

Click here to see the Celignis Analysis Packages that determine Heating (Calorific) Value

Request a QuoteHeating (Calorific) Value

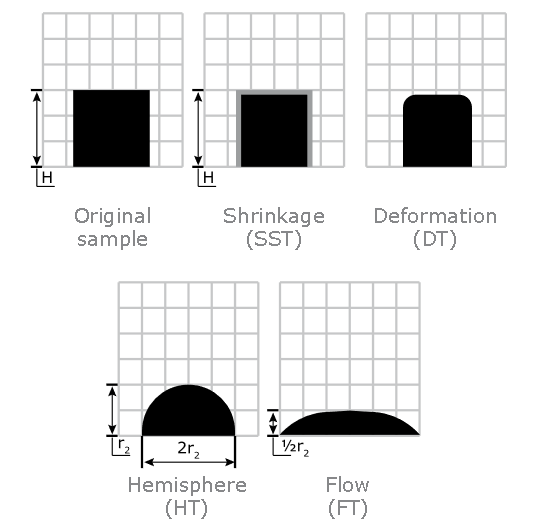

Ash Melting Behaviour of Sugarcane Bagasse

Ash Shrinkage Starting Temperature (SST) - This occurs when the area of the test piece of Sugarcane Bagasse ash falls below 95% of the original test piece area.

Ash Deformation Temperature (DT) - The temperature at which the first signs of rounding of the edges of the test piece occurs due to melting.

Ash Hemisphere Temperature (HT) - When the test piece of Sugarcane Bagasse ash forms a hemisphere (i.e. the height becomes equal to half the base diameter).

Ash Flow Temperature (FT) - The temperature at which the Sugarcane Bagasse ash is spread out over the supporting tile in a layer, the height of which is half of the test piece at the hemisphere temperature.

Click here to see the Celignis Analysis Packages that determine Ash Melting Behaviour

Request a QuoteAsh Melting Behaviour

Major and Minor Elements in Sugarcane Bagasse

We can also determine the levels of 13 different minor elements (such as arsenic, copper, and zinc) that may be present in Sugarcane Bagasse.

Click here to see the Celignis Analysis Packages that determine Major and Minor Elements

Request a QuoteMajor and Minor Elements

Analysis of Sugarcane Bagasse for Anaerobic Digestion

Biomethane potential (BMP) of Sugarcane Bagasse

At Celignis we can provide you with crucial data on feedstock suitability for AD as well as on the composition of process residues. For example, we can determine the biomethane potential (BMP) of Sugarcane Bagasse. The BMP can be considered to be the experimental theoretical maximum amount of methane produced from a feedstock. We moniotor the volume of biogas produced allowing for a cumulative plot over time, accessed via the Celignis Database. Our BMP packages also involve routine analysis of biogas composition (biomethane, carbon dioxide, hydrogen sulphide, ammonia, oxygen). We also provide detailed analysis of the digestate, the residue that remains after a sample has been digested. Our expertise in lignocellulosic analysis can allow for detailed insight regarding the fate of the different biogenic polymers during digestion.

Click here to see the Celignis Analysis Packages that determine BMP

Request a QuoteBMP

Physical Properties of Sugarcane Bagasse

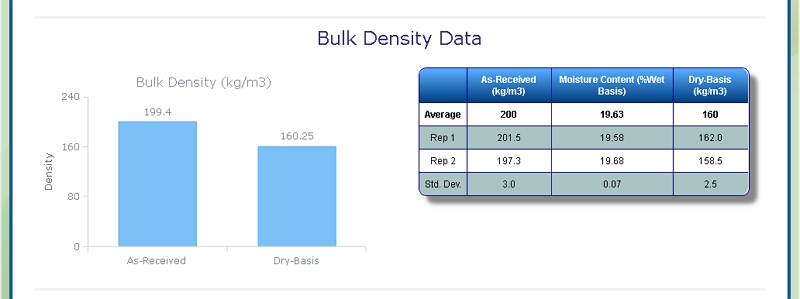

Bulk Density of Sugarcane Bagasse

At Celignis we can determine the bulk density of biomass samples, including Sugarcane Bagasse, according to ISO standard 17828 (2015). This method requires the biomass to be in an appropriate form (chips or powder) for density determination.

Click here to see the Celignis Analysis Packages that determine Bulk Density

Request a QuoteBulk Density

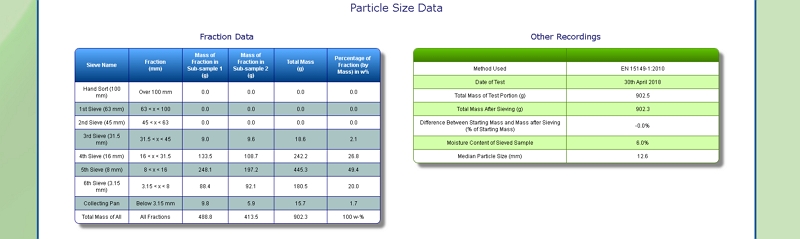

Particle Size of Sugarcane Bagasse

Our lab is equipped with a Retsch AS 400 sieve shaker. It can accommodate sieves of up to 40 cm diameter, corresponding to a surface area of 1256 square centimetres. This allows us to determine the particle size distribution of a range of samples, including Sugarcane Bagasse, by following European Standard methods EN 15149- 1:2010 and EN 15149-2:2010.

Click here to see the Celignis Analysis Packages that determine Particle Size

Request a QuoteParticle Size

The DIBANET process chain, as a result of its patented pre-treatment stage, has significantly increased the yields of levulinic acid, formic acid, and furfural beyond what was considered to be the state of the art. By fractionating lignocellulosic biomass into its three main polymers (cellulose, hemicellulose, lignin) it has also allowed for lignin to be recovered and sold as a higher-value product. These developments have meant that the amount of acid hydrolysis residues (AHRs) that have been produced are significantly (up to 88%) less than in the Biofine process. These AHRs are required to provide process heat for DIBANET. Direct combustion is the most efficient means for doing this. If such combustion does not occur and the AHRs are instead used in other processes, e.g. pyrolysis and gasification, then more biomass will need to be purchased to fuel the core DIBANET process. The AHRs have not been proven to be superior to virgin biomass when put through these thermochemical processes. Indeed, many of the results from DIBANET Work Package 4 indicate the opposite. Hence, given that DIBANET, and the modelling of its optimal configuration, is designed on the basis of an integrated process, centred on the core element of the acid hydrolysis of biomass, then combustion is the only viable end use for the AHRs.

| ||

This document is the result of the evaluation of biomass feedstocks, from Europe and Latin America, that took place as part of the DIBANET project. That project is co-financed from the 7 th Framework Programme for Research and Technological Demonstration of the European Union. (Title: Enhancing international cooperation between the EU and Latin America in the field of biofuels; Grant Agreement No: 227248-2).

| |||

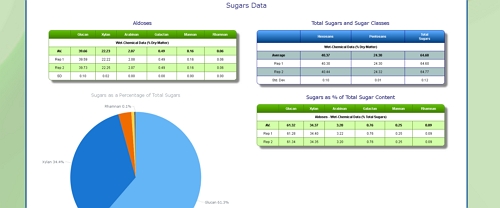

The processing of lignocellulosic materials in modern biorefineries will allow for the

production of transport fuels and platform chemicals that could replace petroleum-derived

products. However, there is a critical lack of relevant detailed compositional information

regarding feedstocks relevant to Ireland and Irish conditions. This research has involved the

collection, preparation, and the analysis, with a high level of precision and accuracy, of a

large number of biomass samples from the waste and agricultural sectors. Not all of the

waste materials analysed are considered suitable for biorefining; for example the total sugar

contents of spent mushroom composts are too low. However, the waste paper/cardboard

that is currently exported from Ireland has a chemical composition that could result in high

biorefinery yields and so could make a significant contribution to Irelandís biofuel demands. | ||