AD Project Development

However, the criteria for the development of a successful AD project are numerous and their relative importances vary according to: the region in which the project is being developed; the technology being implemented; and the feedstocks being processed, among other factors.

Evaluating Your Feedstock(s)

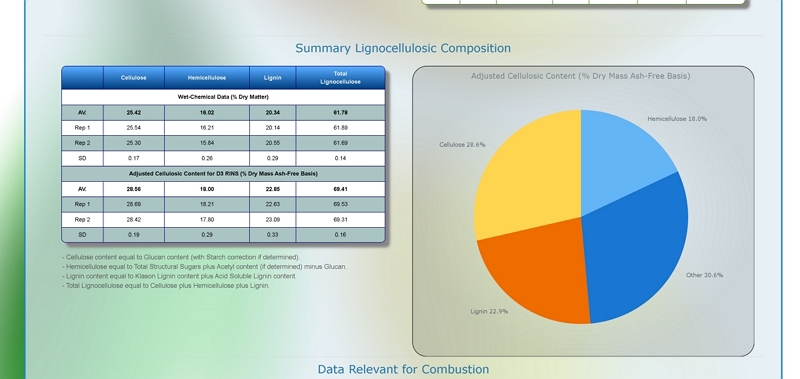

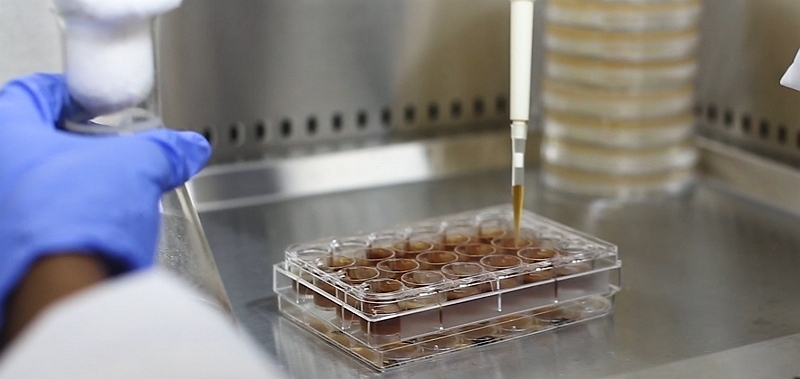

If your Project is focused on the digestion of a specific feedstock (or number of feedstocks) then we will focus our initial work on the detailed compositional analyses and

digestion (batch and continuous) experiments on these feedstocks.

We can suggest, based on these results, the most appropriate AD technology (e.g. UASB or CSTR) for your feedstock(s) and we can also look at addressing any issues

that may arise from the use of these feedstocks, for example feedstock toxicities and nutrient imbalances.

Choosing Feedstock(s) for Your Technology

Alternatively, you may be open to using different feedstocks but fixed with regards to the technology and size of AD process that you will be developing. In that instance we can audit a range of different feedstocks that you have available within the catchment area and evaluate which of these would be most suitable for the selected process and would allow for optimal biomethane yields and/or project revenues. We can then undertake lab-scale experiments where the co-feeding of feedstocks, and the supplementation of nutrients and/or microbes, is optimised.Technoeconomic Analyses (TEAs)

Our TEAs can take places at several stages, and to varying levels of detail, during the project development process. We can explore various options (e.g. differing reactor sizes, variable levels of subsidies, feedstock supply curves) to investigate their relative impacts upon key project financial metrics (e.g. IRR, Payback Period etc.).We can also undertake Life Cycle Analyses to explore the carbon intensity of the process and we can examine how the project can fit under existing rgulatory and support frameworks (e.g. LCFS, D3 RINS, RED II etc.).Risk Evaluations

Based on our expertise in biological consultations, biomass feedstocks, and process design, we can undertake an external review of your plans for your future AD facility with a target of identifiying areas in which the project can be improved and elements of the project that may be exposed to higher levels of risk. We then work on identifying and recommending risk-mitigation strategies.Changes in Feedstock

If you are looking to change the feedstock(s) being processed in your AD plant, or just to modify the relative proportion each feedstock contributes to the total mix, we would strongly recommend that these changes are first tested at the lab-scale. This will allow for the effects of these adjustments, on biogas/biomethane yields and other important process parameters, to be understood and for approriate modifications to be made to the planned activities so that plant performance will not be negatively affected. Undertaking such modifications directly at the plant would mean that you run the risk of reducing digester yields or, potentially, of causing a digester crash.Ensuring Stable Digester Performance

In an ideal world there would be no performance issues with digesters as they would always operate under stable conditions. This would avoid the revenue losses associated with reduced efficiencies and would also mean that there would be no risk of potentially catastrophic digester crashes. The regular collection of relevant process parameters can help significantly with regards to identifying warning-signs of imminent drops in reactor performance and so can allow for appropriate mitigation strategies to be employed. These strategies would result in the predicted drop in performance being avoided and would ensure that the digester remains stable.In order for this approach to work most effectively, the process analytical data should be interpreted by someone that is an expert in the process and biology of AD systems. At Celignis we have such experts who provide valued biological consultancy services to clients in the AD/RNG sector using such process data. We can be sent samples and obtain the analytical data ourselves within our labs or we can use analytical data that you provide us. We can also do a historical audit of your process parameters and correlate these to performance metrics of your digesters. From this work we can identify warning-signs and causative factors for prior events, allowing for appropriate mitigation strategies to be developed for avoiding such issues in the future.

However, the potential avenues for valorising the digestate are highly dependent on its physical and chemical parameters. We offer an array of different analysis packages for digestate that help our clients figure out the best use for this side-stream. We are also familiar with regulatory requirements with regards to the different end-uses of digestate.

Additionally, we can provide further support in terms of the technoeconomic analysis of the various options for using, selling or upgrading your digestate.

Click here to read more about our services for AD digestates.

AD Feedstock Mixture Optimisation Tool

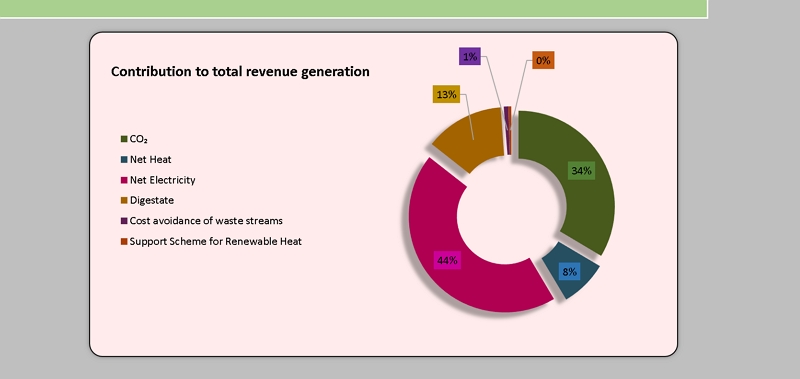

Celignis was approached by a large beverage production company to determine the feasibility of utilising their waste streams for biogas production and to determine the additional feedstock requirement to meet the full plant energy demand. Celignis performed the required biological and chemical analysis of the facility's waste streams and developed a spreadsheet tool for feedstock mixtures design to allow the conversion of the sugar and acid rich waste stream to biogas and to meet the energy requirements of the company.The tool considered seasonality of the locally-available feedstock that could be used as co-feed with the sugar rich waste streams. Also considered, while designing the feedstock mixtures, were Renewable Energy Directive (RED) II GHG emission targets and waste to energy crops ratio.

Greenhouse has (GHG) emission reductions and carbon dioxide that could be captured and the total revenue generation from biogas and CO2 were also estimated. The tool allowed the company to make informed decisions on the project and understand the biogas potential and feedstock requirements to meet the target power requirement.

Continuous Digestions for Improved OLR

Celignis carried out continuous digestion experiments, for a company that produces biogas from OFMSW (the organic fraction of municipal solid waste) and other waste streams, in order to determine the maximum achievable organic loading rate and optimum feedstock mixtures. These experiments also determined the minimum organic loading rate to maintain the health of the plant in the scenarios where feedstock availability was limited.This continuous digestion data, combined with the specific microbial activity tests (Specific Hydrolytic Potential (SHP), Specific Acidogenic Potential (SAP), and Specific Methanogenic Potential (SMP)) on the digestate, provided the plant with the microbial activity in the operational digester and adaptation strategies for the new feedstock.

The full suite of tests and data analysis performed by Celignis allowed the biogas plant operator understand the limitations of the feedstock, feedstock underload/overload effects, optimum feedstock loading, and process indicator (volatile fatty acids (VFAs), alkalinity, biogas production, biogas composition) ranges at different organic loading rates and feedstock mixtures. This allowed adapting the strategies in the biogas plant for maintaining the plant health under feedstock supply and composition variations.

Stabilising Plant Performance

A Germany-based biogas company that operates dozens of AD/RNG plants in Europe and the UK approached Celignis to support them in optimising their plant operations to allow for more consistent outputs and reduced downtime. As a result, Celignis provided Biological Consultancy support which involved us analysing the plant process data in terms of: feedstock loading (organic loading rate); recirculation strategies; biogas composition and yield; volatile fatty acids (VFAs); and alkalinity.This detailed analysis of the plant process data allowed us to provide operational limits and indicators in the plant beyond common indicators such as VFA and alkalinity and acetic acid to propionic acid ratios (isoforms of volatile fatty acids, presence of traces of hydrogen in the biogas, Hydrogen sulphide and ammonia) and provided green, yellow and red zones for each of the indicators.

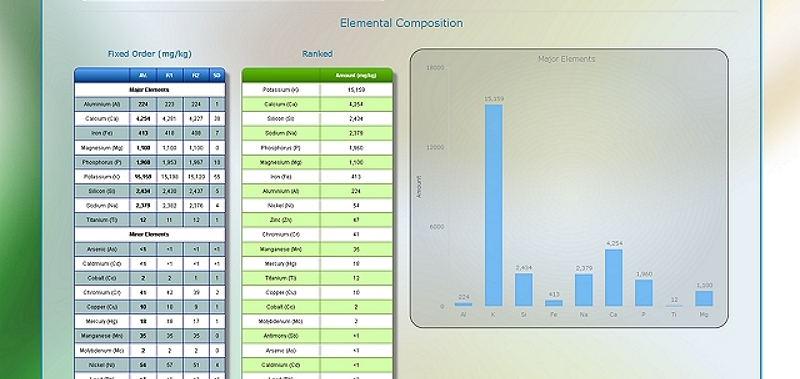

In addition to this, Celignis also developed a tool for the company to allow self-design of major and minor elements (nutrients) for the biogas plants based on the feed chemical composition. The tool was designed to be suitable for mono and co-digestion and allows for change from one feedstock to other, and for addition of a new feedstock to the co-digestion mix, without there being a negative affecting on plant performance.

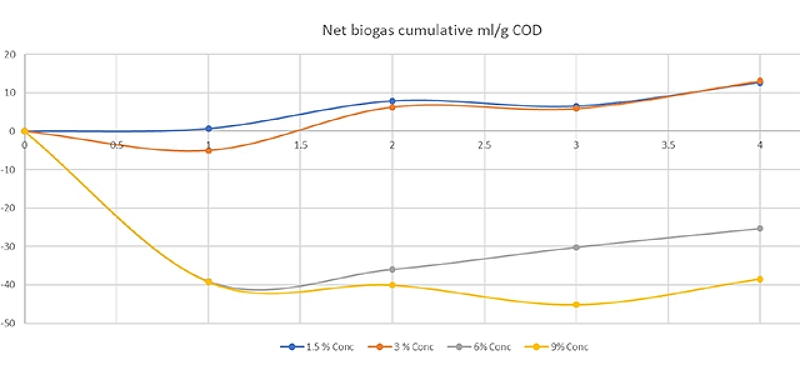

Feed Limits for New AD Streams

A biogas plant started underperforming when a new feedstock was used as co-feed to the plant. As the plant received an important gate-fee for this new feedstock, they did not want to discontinue its use but to instead use it in a controlled and scientifically-driven manner. Celignis was asked to provide support for: determining the toxic effects of the feedstock; the causes of it; and to provide feeding limits.Celignis undertook chemical analyses on the feedstock and then custom-designed and performed Anaerobic Toxicity Assays (ATA) for the waste stream based on the analytical data. These experiments allowed for the determination of threshold feedstock-loadings, as co-feed, in order to avoid the toxic/inhibitory effects of the feedstocks.

The biogas plant is now benefiting from Celignis's support since they can make informed decisions on using feedstocks coming various process industries and so can maintain healthy digestion while incorporating new waste streams into the feed-mix of the RNG plant.

Lalitha Gottumukkala

Founder and Lead of Celignis AD, CIO of Celignis

PhD

<p style="text-align: left;">Has a deep understanding of all biological and chemical aspects of anaerobic digestion. Has developed Celignis into a renowned provider of AD services to a global network of clients.</p>

Oscar Bedzo

Technoeconomic Analysis Lead

PhD

<p style="text-align: left;">A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.</p>

Global Recognition as AD/RNG Experts

Biomethane Potential

Continuous Digestions

Toxicity Assays

Process Optimisations

Feedstock Analysis

Biological Consultations

Specific Microbial Activity

Technoeconomic Analyses

Digestate Analysis

Process Parameters

Nutrient Supplementations

Fruit juice processing generates large volumes of organic waste, including pomace, retentate, and waste apples, that are a challenge to manage. Anaerobic digestion (AD) allows for conversion of these wastes into biogas; however, their high acidity and low buffering capacity limits AD process stability, leading to reduced methane yield. In this study, co-digestion with manure and lignocellulosic biomass (LCB) was assessed. A five-factor mixture design was used to test different combinations on a bench scale, selected based-on seasonal fruit waste availability. Process performance was assessed based-on methane yield and volatile fatty acids before and after AD. Feedstock mixture representing an off-season blend of 20% pomace, 30% retentate and 50% manure, as well as an in-season blends of 20% waste apples, 30% pomace, 30% retentate, and 20% manure, were found to maximise the biomethane yield. Supplementation with at least 20% manure was essential for fruit waste digestion. Replacing a portion of the fruit waste with lignocellulose in the anaerobic digestion significantly improved the methane yield and prevented an “acid crash”. It was found that 30% LCB and 20% manure supplementation were the minimum required for anaerobic digestion process stability and yield for both in- and off-season fruit harvesting and processing. | ||

This investigation explores the enhancement of CH4 generation in anaerobic digesters (AD) via in-situ renewable hydrogen injection utilising four exotic crop wastes and a crop (five feedstocks). The substrates are yam, cassava, and cocoyam peel (YP, CP and CYP), rice husk (RH) and finger millet seeds (FMS). Biomethane Potential (BMP) Tests, followed by AD experiments with food waste inoculum (FWI), were conducted in triplicate under mesophilic conditions (37 C), utilising an anaerobic model (ANM) test rig. The last phase of the experimental campaign is bio-methanation to upgrade CH4 purity. CYP and YP showed 233% and 81.5% higher gas yields, respectively, with CH4 content improvements up to 38.5%. However, CP emerged as the optimal feedstock, hence the primary substrate utilised in the AD, supporting hydrogenotrophic methanogenesis (HM) and CO2 to CH4 conversion. Consequently, MATLAB-based kinetic modelling confirmed the Richard equation as the best fit predictor. The novelty of this study lies in the innovative incorporation of in-situ H2 injection (0.67 ml/min), bubble mixing and mass transfer to enhance CH4 from tropical crop waste (cassava peel), a widely available yet underutilised feedstock specific to Plateau State, Nigeria. Additionally, integrating computational fluid dynamics (CFD) and bioprocess kinetic modelling provides a comprehensive framework for understanding the parameterisation and optimising system dynamics. This consolidates the research contribution to the experimental optimisation of decentralised biogas systems, facilitating sustainable energy solutions for pipeline quality in tropical regions. | |

As the global population rises, agriculture and industry are under increasing pressure to become more sustainable in meeting this growing demand, while minimizing impacts on global emissions, land use change, and biodiversity. The development of efficient and symbiotic local bioeconomies can help to respond to this challenge by using land, resources, and side streams in efficient ways tailored to the needs of different regions. Green biorefineries offer a unique opportunity for regions with abundant grasslands to use this primary resource more sustainably, providing feed for cows, while also generating feed for monogastric animals, along with the co-production of biomaterials and energy. The current study investigates the impact of a green biorefinery co-product, leaf protein concentrate (LPC), for input to a pig farm, assessing its impact on pig diets, and the extended impact on the bioenergy performance of the pig farm. The study found that LPC replaced soya bean meal at a 50% displacement rate, with pigs showing positive performance in intake and weight gain. Based on laboratory analysis, the resulting pig slurry demonstrated a higher biogas content and 26% higher biomethane potential compared with the control slurry. The findings demonstrate some of the local synergies between agricultural sectors that can be achieved through extended green biorefinery development, and the benefits for local bioeconomy actors. | ||

Anaerobic digestion (AD) is a bioprocess technology that integrates into circular economy systems, which produce renewable energy and biofertilizer whilst reducing greenhouse gas emissions. However, improvements in biogas production efficiency are needed in dealing with lignocellulosic biomass. The state-of-the-art of AD technology is discussed, with emphasis on feedstock digestibility and operational difficulty. Solutions to these challenges including for pre-treatment and bioaugmentation are reviewed. This article proposes an innovative integrated system combining alkali pre-treatment, temperature-phased AD and bioaugmentation techniques. The integrated system as modelled has a targeted potential to achieve a biodegradability index of 90% while increasing methane production by 47% compared to conventional AD. The methane productivity may also be improved by a target reduction in retention time from 30 to 20 days. This, if realized has the potential to lower energy production cost and the levelized cost of abatement to facilitate an increased resource of sustainable commercially viable biomethane. | ||

Global warming and climate change are imminent threats to the future of humankind. A shift from the current reliance on fossil fuels to renewable energy is key to mitigating the impacts of climate change. Biological raw materials and residues can play a key role in this transition through technologies such as anaerobic digestion. However, biological raw materials must also meet other existing food, feed and material needs. Green biorefinery is an innovative concept in which green biomass, such as grass, is processed to obtain a variety of protein products, value-added co-products and renewable energy, helping to meet many needs from a single source. In this study, an analysis has been conducted to understand the renewable energy potential of green biorefinery by-products and residues, including grass whey, de-FOS whey and press cake. Using anaerobic digestion, the biogas and biomethane potential of these samples have been analyzed. An analysis of the fertiliser potential of the resulting digestate by-products has also been undertaken. All the feedstocks tested were found to be suitable for biogas production with grass whey, the most suitable candidate with a biogas and biomethane production yield of 895.8 and 544.6 L/kg VS, respectively, followed by de-FOS whey and press cake (597.4/520.3 L/kg VS and 510.7/300.3 L/kg VS, respectively). The results show considerable potential for utilizing biorefinery by-products as a source for renewable energy production, even after several value-added products have been co-produced. | ||

This study considered the possibility of reducing the environmental footprint of paper and pulp industry by producing bioenergy from paper sludge by using process wastewater instead of fresh water, and reclaiming water trapped in paper sludge. Experimental studies are conducted with streams from three different pulp and paper mills (virgin pulp mill (VP), corrugated recycling mill (CR), tissue printed recycling mill (TPR)) for sequential bioethanol and biogas production with simultaneous reclamation of water from paper sludge (PS). Total energy yields of 9215, 6387, 5278 MJ/tonne dry PS for VP, CR and TPR, respectively, were obtained for ethanol-biogas production. Virgin pulp paper sludge gave the highest yield for ethanol and biogas in stand-alone processes (275.4 kg and 67.7 kg per ton dry PS respectively) and also highest energy conversion efficiency (55%) in sequential process compared with CR and TPR. Energy and environmental case study conducted on virgin pulp mill has proven the possibility of using paper sludge bioenergy to reduce energy demand by 10%, while reclaiming 82% of the water from the PS, reducing greenhouse gas emissions (GHG) by 3 times and producing solids suitable for land spreading. | |

Miscanthus giganteous is probably the most fast growing and low nutrient bioenergy crop among lignocellulosic feedstocks. Despite its significant content in fermentable sugars, currently Miscanthus biomass is not used for biogas/methane production due to the high-lignin and low moisture content in the winter/spring harvest as well as cellulose crystallinity, which limit access to enzymatic action for all lignocellulosic feedstock. This study identified that a photocatalytic pretreatment prior to anaerobic digestion helps increase the substrate's biodegradability by oxidising the lignin fraction, leading to increased methane yield up to 46% compared to the untreated. A novel photocatalyst was manufactured by reactive magnetron-sputtering deposition of TiO2 particles onto natural zeolite supports, which provided important trace elements for the anaerobic digestion process and retained a large surface area that acted as biofilm to boost growth of the microbial community. A load of 2% w/w catalyst in the bioreactor after 3 h of photocatalytic treatment led to 220 mLN gVS-1, with a net energy balance that is achieved for the whole process when treating the dispersed phase suspension at concentrations above 10 g m-3. | |

Laminaria. sp. seaweeds have been recognised the potential to greatly contribute to the generation of renewable gaseous fuel via anaerobic digestion. Seaweed feedstock has been documented to consistently vary its biochemical composition with seasons, which affects stability of biomethane production. As currently seaweeds are too costly for use as third generation feedstock for biofuels, this paper investigates the biogas potential of the algal waste streams from the existing bio-industry. Analytical tests identified an improved digestibility of extracted residues (C:N>20). Fermentation with and without inoculum acclimatation revealed the interaction between compositional seasonality and inoculum type to significantly affect methane production from the extracted samples. Summer's composition has the most significant impact on methane production, with best results achieved with acclimatised inoculum (433ml CH4 gVS-1 and final biodegradation of about 90%). Organics concentration (tCOD) and ash:volatile (A:V) ratio also play a major role in the bioconversion process. In particular, digestion with acclimatised inoculum better responds to A:V fluctuations across seasons, which produced the highest average methane yield of 334ml gVS-1. Pretreatments are required to increase the biodegradation index in spring and summer when not using acclimatation. | |

Very recently, integrated biorefinery approaches are being developed with the aim to produce high-value products for a variety of industries in conjunction with green energy from sustainable biomass. Macroalgae (seaweed) have been regarded as more sustainable compared to terrestrial crops, since they do not occupy land for growth. Macroalgal biomass changes greatly according to species and harvest season, which affects its chemical energy potential. This study was conducted seasonally on five species of brown seaweed over a yearlong period to investigate the effects of chemical composition variations, bioproducts extraction processes and inoculum acclimatation on methane production. As a result of the bioproducts extraction, it was found the seaweed residues exhibit a great potential to produce methane. Stoichiometric methane yield and C:N ratio changed in favour of an improved digestibility with bioconversion rates greater than 70% in some instances, i.e. achieved by Laminaria species and on the West coast Fucus serratus. The two Laminaria species investigated also presented the highest CH4 production rate, with Laminaria digitata reaching 523?mL CH4 gVS-1 and L. saccharina peaking at 535?mL CH4 gVS-1 with acclimatised and non-acclimatised sludge respectively. | |

The paper and pulp industry is one of the major industries that generate large amount of solid waste with high moisture content. Numerous opportunities exist for valorisation of waste paper sludge, although this review focuses on primary sludge with high cellulose content. The most mature options for paper sludge valorisation are fermentation, anaerobic digestion and pyrolysis. In this review, biochemical and thermal processes are considered individually and also as integrated biorefinery. The objective of integrated biorefinery is to reduce or avoid paper sludge disposal by landfilling, water reclamation and value addition. Assessment of selected processes for biorefinery varies from a detailed analysis of a single process to high level optimisation and integration of the processes, which allow the initial assessment and comparison of technologies. This data can be used to provide key stakeholders with a roadmap of technologies that can generate economic benefits, and reduce carbon wastage and pollution load. | ||

Growth inhibition kinetics of a novel non-acetone forming butanol producer, Clostridium sporogenes BE01, was studied under varying concentrations of acetic and formic acids in rice straw hydrolysate medium. Both the organic acids were considered as inhibitors as they could inhibit the growth of the bacterium, and the inhibition constants were determined to be 1.6 and 0.76 g/L, respectively, for acetic acid and formic acid. Amberlite resins�XAD 4, XAD 7, XAD 16, and an anion exchange resin�Seralite 400 were tested for the efficient removal of these acidic inhibitors along with minimal adsorption of sugars and essential minerals present in the hydrolysate. Seralite 400 was an efficient adsorbent of acids, with minimal affinity towards minerals and sugars. Butanol production was evaluated to emphasize the effect of minerals loss and acids removal by the resins during detoxification. | |