Processes for the Extraction of Bioactives from Bark

Background

Many bioactives and other high-value plant constituents can be considered to be a part of the biomass extractives, which are defined as extraneous components that may be separated from the insoluble cell wall material by their solubility in water or neutral organic solvents.

Click here to learn more about the ways in which bioprocesses can be developed to efficiently and sustainably extract these extractives from biomass, with particular selectivity towards the bioactives and chemicals of interest.

Get more info...Extraction Processes

Bioactives in Bark

In the manufacture of wood materials, bark is removed and discarded or burnt for fuel, an inefficient valorisation method considering the interesting and diverse chemistry of this resource.

Bark is rich in bioactive components such as phenolics, tannins, flavonoids, terpenoids, sterols, and glycosides.

Bark should be washed and ground (mechanical pretreatment) to increase the extraction efficiency. Based on the class of target bioactive compounds, different types of solvents and extraction methods are required.

Hydrodistillation is the common method used for extraction of oils and extractives from barks. The yields can be improved by maintaining the bioactivity by using efficient advanced extraction methods such as microwave treatment, ultrasonic extraction, pressurised liquid extraction, sub-critical and super critical fluid extraction methods.

Further Info on Classes of Bioactives in Bark

Examples of some terpenoids found in bark are listed below:

- Pinene - A monoterpene commonly found in the bark of pine trees that has a distinctive pine-like aroma. There are two structural isomers of pinene found in nature: alpha-pinene and beta-pinene, with alpha-pinene being more prevalent.

- Cedrol - A sesquiterpene alcohol found in the bark of cedar trees. It has a distinctive woody, cedar-like aroma and is used in the perfume industry.

- Camphor - A bicyclic monoterpene found in the bark of the camphor tree. It has a strong, minty aroma and a cooling sensation. Camphor is used in medicinal products such as ointments and inhalants.

- Taxol - A diterpene found in the bark of the Pacific Yew tree. It has been found to inhibit the growth of cancer cells and is used as a chemotherapy drug.

- Limonene - This is a monoterpene that is found in the bark of citrus trees. Limonene has a strong, citrusy aroma and is used in a wide range of products from cleaning agents to cosmetics.

- Betulin and Betulinic Acid - These are triterpenoids found in the bark of the white birch tree. Both compounds have been studied for their potential anti-inflammatory and anti-cancer properties. Click here to read about Celignis's work with the extraction and purification of betulin.

Get more info...Terpenoids

Examples of some glycosides found in bark are listed below:

- Salicin - Found in the bark of willow trees and has pain-relieving and anti-inflammatory properties. Once ingested, salicin is converted into salicylic acid in the body. This compound served as the initial inspiration for the synthesis of acetylsalicylic acid, better known as aspirin.

- Arbutin - This glycoside is found in the bark of a number of tree species, including the bearberry tree. Arbutin has been used in traditional medicine for urinary tract health, and it is also used in cosmetic products due to its skin-lightening properties.

- Paeoniflorin - Present in the bark of the tree peony, it is known for its potential anti-inflammatory, analgesic, and neuroprotective properties.

- Amygdalin - A cyanogenic glycoside found in the bark and seeds of several plants, including some types of fruit trees.

- Oleuropein - Found in the bark (and leaves) of olive trees, it has antioxidant and anti-inflammatory properties and has been studied for potential health benefits related to heart health and blood sugar regulation.

- Aesculin - A coumarin glycoside that is found in the bark of the horse chestnut tree. Aesculin has various potential health benefits, including anti-inflammatory and analgesic effects.

Get more info...Glycosides

Examples of some flavonoids found in bark are listed below:

- Quercetin - This is one of the most abundant flavonoids found in plants and is known for its antioxidant and anti-inflammatory properties. It is found in the bark of some trees, such as oak.

- Rutin - Also known as rutoside, rutin is a flavonoid that is found in numerous plant species, including the bark of some trees. Rutin is known for its antioxidant properties and potential benefits for blood vessel health.

- Epicatechin - This is a type of flavan-3-ol, a subclass of flavonoids, found in a variety of plants including the bark of certain tree species. Epicatechin has been researched for its potential cardiovascular benefits.

- Kaempferol - This flavonoid is found in a variety of plant foods and in the bark of some trees. It is known for its antioxidant properties and has been studied for potential anti-cancer and anti-inflammatory effects.

- Proanthocyanidins - Also known as condensed tannins, these complex flavonoids are found in many plants, including tree bark. They're known for their antioxidant properties and contribute to the astringent qualities of many plant foods.

Get more info...Flavonoids

Some points regarding tannins in bark are provided below:

- Role - Tannins play essential roles in the tree's defenses against pests and diseases, and they contribute to the tree's growth and repair.

- Hydrolysable Tannins - These tannins can be hydrolyzed into simpler phenolic compounds, such as gallic acid or ellagic acid, and a sugar molecule. They are found in the bark of many tree species, including oak, chestnut, and myrobalan.

- Condensed Tannins - Also known as proanthocyanidins, these tannins are polymers of flavonoid units and are not readily hydrolysed. They are found in high quantities in the bark of some trees, like pine and spruce.

- Industry Applications - Bark tannins are widely used in industry. For instance, the bark of oak trees is a major source of tannins used in the tanning of leather. During the tanning process, the tannins bind to the collagen proteins in the animal hides, making them resistant to decomposition and conferring durability.

- Health Applications - Bark tannins have antioxidant properties and potential antimicrobial, antiviral, and anticancer effects.

Get more info...Tannins

Examples of some sterols found in bark are listed below:

- Beta-Sitosterol - A very common plant sterol that has been studied for its potential benefits for heart health and its anti-inflammatory properties.

- Stigmasterol - Also found in some bark extracts, stigmasterol has been researched for its potential anti-inflammatory and antioxidant properties.

- Campesterol - This sterol, found in the bark of some trees, has been studied for its potential cardiovascular benefits.

- Cycloartenol - This is a precursor of other plant sterols and is involved in the biosynthesis of steroidal saponins and other complex molecules in plants.

Get more info...Sterols

Examples of some alkaloids found in tree bark are listed below:

- Quinine - This alkaloid, found in the bark of the cinchona tree, was the first effective treatment for malaria. It is also used as a flavoring in tonic water.

- Yohimbine - Found in the bark of the Yohimbe tree, native to Africa, yohimbine is used for its stimulant and aphrodisiac effects.

- Berberine - This alkaloid is found in the bark of the cork tree and the Oregon grape tree. It has been studied for its potential benefits in regulating blood sugar and cholesterol levels.

- Akuammicine - Found in the bark of the Picralima nitida tree (also known as the Akuamma tree), akuammicine has analgesic properties.

- Taxine - This is a group of alkaloids found in the bark (and other parts) of yew trees. Taxine alkaloids are highly toxic and can cause serious cardiac effects.

- Camptothecin - Found in the bark of the Camptotheca acuminata tree, also known as the "happy tree", camptothecin has demonstrated anti-cancer properties and is used as a chemotherapeutic agent.

Get more info...Sterols

Examples of some common resins found in barks are provided below:

- Pine Bark Resin - The resin has been used for a wide range of purposes, from making varnish and adhesives to treating wounds in traditional medicine.

- Spruce Bark Resin - Has been used in traditional medicine for its antimicrobial properties and it is also used in the manufacture of certain products like varnishes and adhesives.

- Frankincense - This resin comes from the bark of trees in the Boswellia genus. It has been used for thousands of years in religious ceremonies, and it is also prized for its potential anti-inflammatory and anticancer properties.

- Myrrh - Like frankincense, myrrh is a resin that is harvested from the bark of trees, specifically those in the Commiphora genus. Myrrh has been used in traditional medicine, as well as in perfumery and religious ceremonies.

- Gum Arabic - This resin comes from the bark of the Acacia senegal tree and other species in the Acacia genus. Gum arabic is used in the food industry as a stabilizer, in the production of inks, and in traditional medicine.

- Copal - This is a term used for the aromatic resins produced by a number of different trees, and it can be harvested from the bark. Copal has been used in the production of varnishes and in traditional medicine.

- Mastic - This resin is produced by the bark of the Pistacia lentiscus tree. It is used in the production of chewing gum, in cooking, and in traditional medicine.

- Balsam Fir Resin - The balsam fir tree (Abies balsamea) produces a resin that is used in traditional medicine, as well as in the manufacture of glues and varnishes.

Get more info...Resins

Analysis of Bioactives in Bark

Feel free to click on the links above to see more information on our methods of analysis for the different classes of bioactives or get in touch with us to request further information and a quotation.

Request a QuoteBioactives Analysis

Bioactives According to Other Plant Fractions

Get more info...Herbal Leaf Extracts

Get more info...Root Extracts

Get more info...Flower Extracts

Get more info...Fruit & Veg Extracts

Get more info...Seed Extracts

Identification of High-Value Chemicals

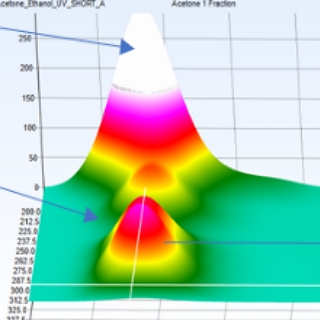

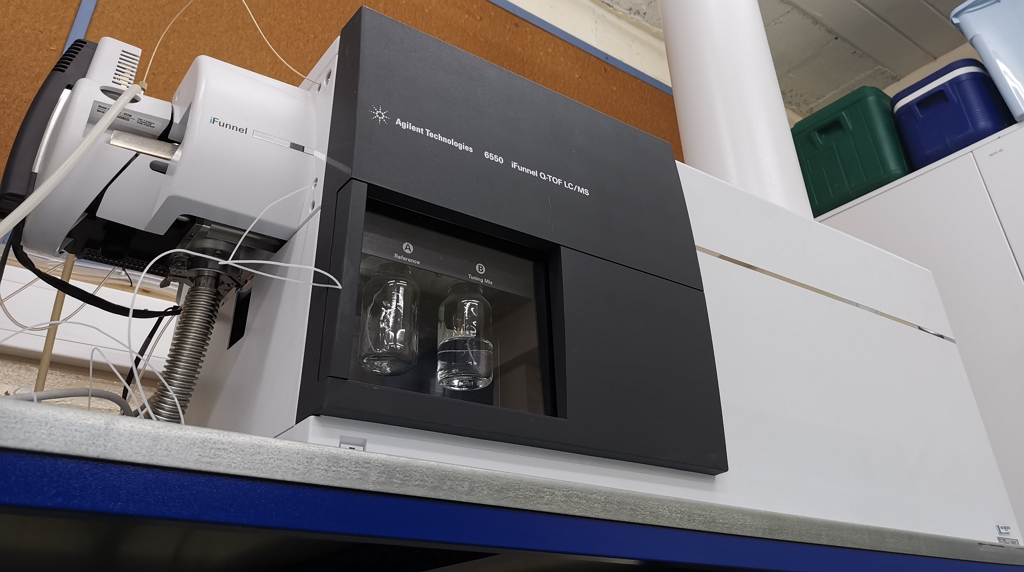

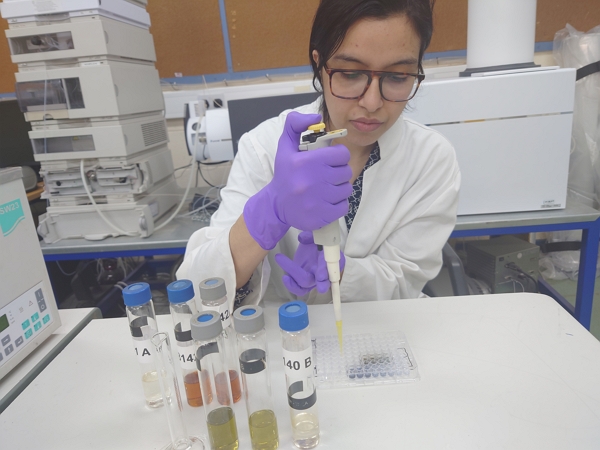

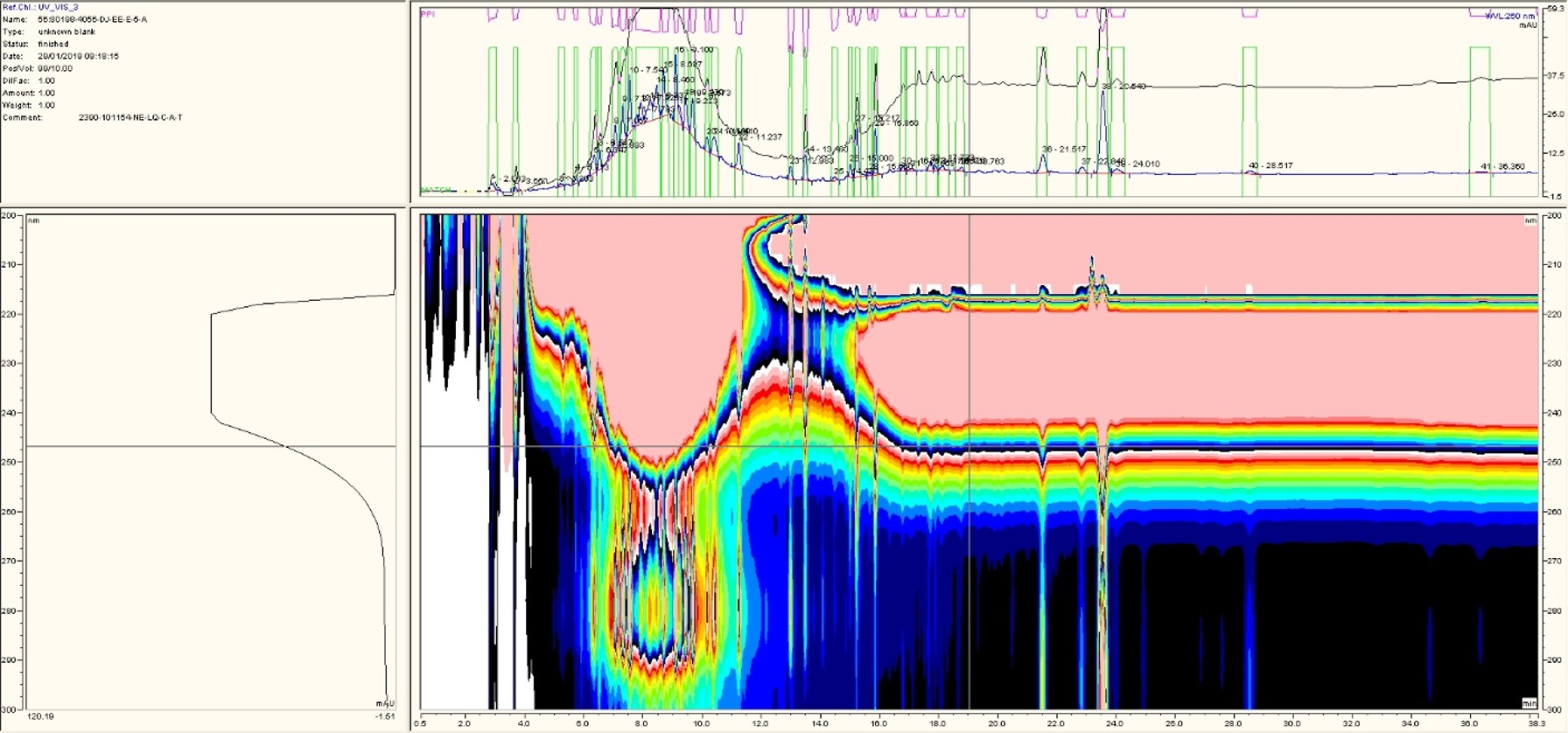

For identification, we firstly get a crude extract from the feedstock, obtained via various approaches, including pressurised liquid extraction. This extract is then profiled using our top-range QTOF-LC/MS system (Agilent iFunnel 6550), which can identify constituents to the femtogram-level, and the spectra and chromatograms reviewed by Sajna, our Bioanalysis Developer. If necessary, we can collect the relevant fractions from the LC system and confirm the identification using a number of different chemical and spectroscopic techniques. We then determine which constituents warrant extraction.Develop an Optimised Extraction Protocol

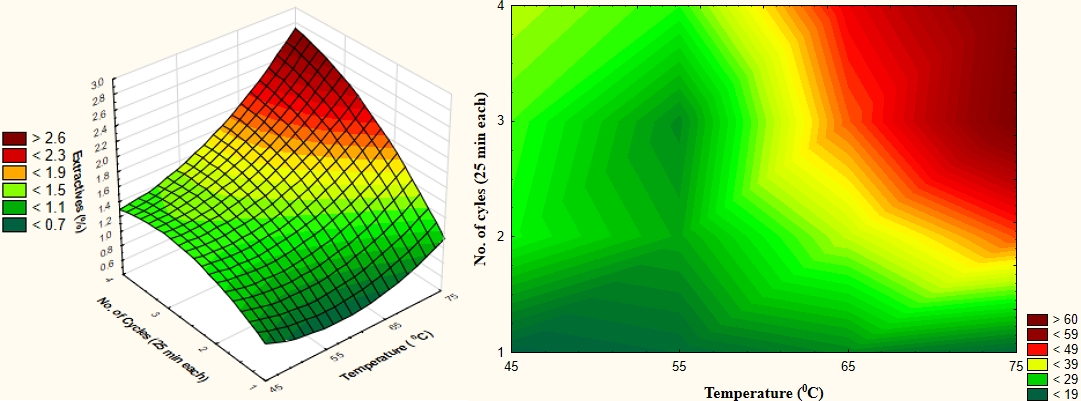

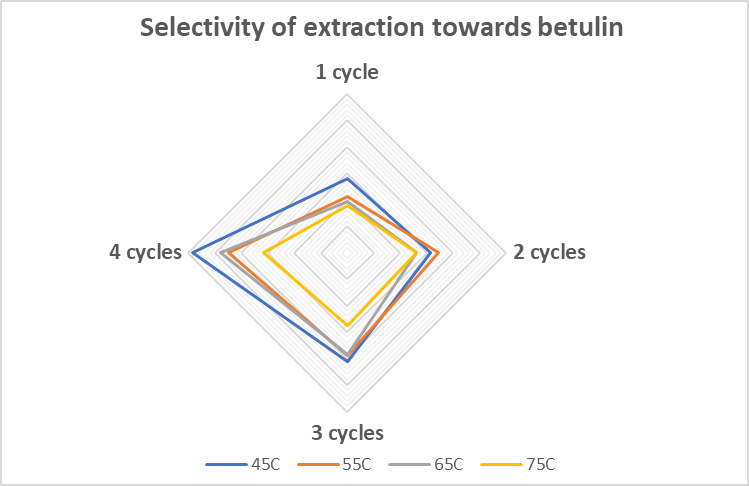

Based on the identified chemical(s) of interest, we can then work on optimising a targeted extraction method. This method considers not only the yield of the target compound(s) but also the chemical and energy costs of the process and the implications for the downstream processing and valorisation of the solid residue. We consider a range of different extraction technologies, solvents, and process conditions.Typically, we first optimise the extraction at lab-scale conditions and then validate the chosen set of conditions at an nehanced scale (i.e. a higher technology readiness level (TRL)).

Separation and Purification of Target Chemical(s)

We can work on a process for the separation and purification of the targeted high value extractive compounds, while considering commercial viability and environmental aspects such as solvent and energy consumption. Based on the particular bioactive compound of interest and the composition of the liquid extract, we can employ a variety of different techniques for separation and purification.Application Testing of Extract or Separated Components

We can test the extract, or the separated compounds of interest, for a variety of different applications. The tests are custom-designed based on the extracted compound. For low molecular weight biomolecules (non food and feed), bioactivity tests, anti-microbial tests, UV absorbance properties, surface activities, and emulsion forming abilities can be tested. For the food and feed related extract fractions, such as proteins and carbohydrate polymers, nutritional properties, anti-nutritional compounds, emulsification, gelation, foaming (together with bioactive properties, in vitro digestibility etc.) are tested.Technoeconomic Analysis of the Process

The Celignis team, including Oscar our chief TEA expert, can undertake a detailed technoeconomic analysis of the developed process. We apply accurate and realistic costing models to determine the CAPEX and OPEX of simulated and pilot scale processes which are then used to determine key economic indicators such as IRR, NPV and payback periods.Our sensitivity analyses can assess the effect of variable costs and revenues, a particularly important aspect to consider given that the sale prices for some bioactive compounds can vary significantly according to their purity and market conditions.

Our preferred approach is to include TEA studies at each stage of the development of the extraction bioprocess, so that the process can be optimised in a commercially-relevant way, followed by a more detailed TEA after the process has been optimised and tested at higher TRL levels.

Click here to read more about the technoeconomic analysis (TEA) services offered by Celignis.

Bioprocess Biomass Extraction Projects - Case Studies

Betulin - UNRAVEL Project

Celignis worked extensively on biomass extraction and the purification of bioactive chemicals in the CBE/BBI project UNRAVEL where the extractives of 25 feedstocks were profiled using our QTOF-LC/MS system. We identified betulin in birch bark as the most attractive compound and subsequently worked on developing an optimised extraction protocol and an isolation/purification process scheme that offered several advantages, in terms of sustainability and safety, over the current art. Click here for a news article on this work.SteamBioAfrica Project

We are also using employing our compositional analysis and purification expertise in the Horizon Europe project SteamBioAfrica where we evaluate and process the liquid condensate obtained from the steam torrefaction process and consider market applications for its constituents, fractions, and derivatives.Celignis is testing the separation of acids, phenolics, and aldehydes for their potential to be used as high value bioactive compounds and biopesticides.

Bioactives Profiling of Tropical Trees

Celignis undertook detailed analysis of a wide variety of tropical hardwood trees for a client. This involved characterisation of different anatomical fractions (e.g. stem wood, bark, foliage). There was a particular focus on the composition of the extractives of these feedstocks. We used our QTOF-LC/MS system to profile the diverse and complex array of bioactive compounds present in the samples. We then evaluated the identified compounds and selected key chemicals that could be of high potential value for sale in different markets. We then undertook a review of these compounds, considering their potential value in various markets, the processes that could be required for their separation and purification, and whether other compounds could also be obtained as part of the extraction/separation process. The final output of the project was a list of top feedstocks and chemicals for future bioprocess development.

With regards to the extraction of bioactives from biomass, the Celignis Bioprocess team members with the most experience in undertaking such projects are listed below. Feel free to contact them to discuss potential projects.

Lalitha Gottumukkala

Founder of Celignis Bioprocess, CIO of Celignis

PhD

<p style="text-align: left;">Has a deep understanding of all biological and chemical aspects of bioproceses. Has developed Celignis into a renowned provider of bioprocess development services to a global network of clients.</p>

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

<p style="text-align: left;">Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.</p>

Sajna KV

Bioanalysis Developer

PhD

<p style="text-align: left;">Our Biomass Detective! Designs, tests, optimizes and validates robust analytical methods for our bioprocess development projects. Such bespoke analysis is key to developing an optimised bioprocess.</p>