Single Cell Oils (SCOs) from Biomass

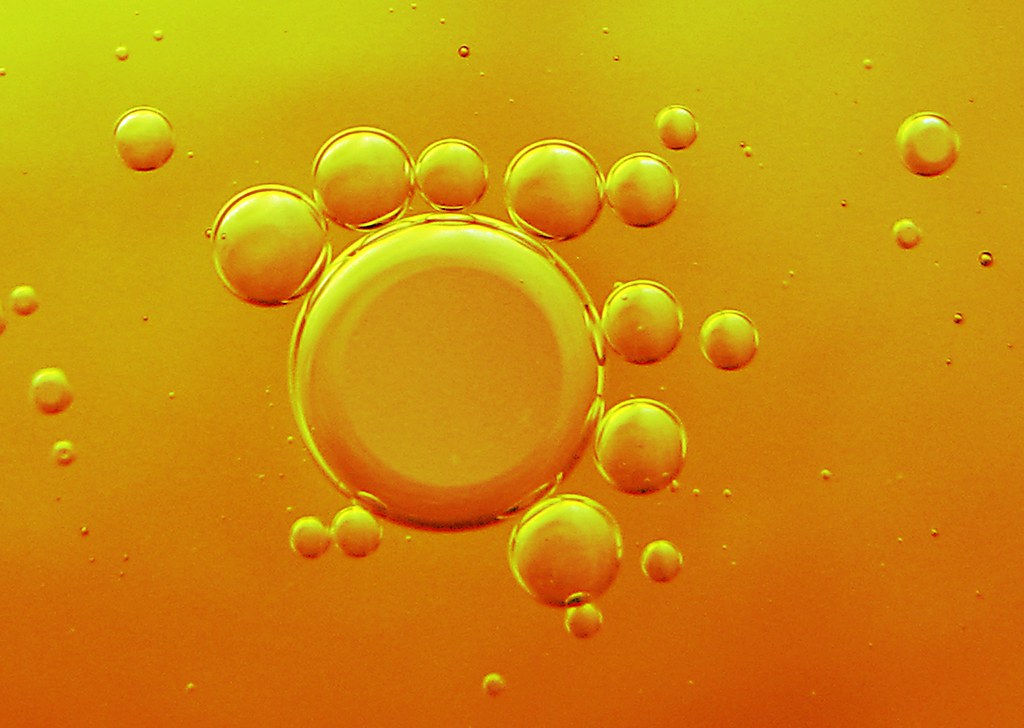

Background to Single Cell Oils (SCOs) Production

Some yeast and fungal strains are capable of producing lipids in a variety of substrates such as different types of

sugars, glycerol, etc. and have wide pH ranges. SCOs are edible oils if they are produced in clean substrates and can be converted to biofuels if industrial by-product streams

are used for their production.

How Celignis Can Help

Our team includes a number of fermentation experts who can work with you on the best process conditions for producing

SCOs.

We can also evaluate the suitability of your process liquids for fermentation and, if necessary, can suggest ways by which they can be detoxified in order to ensure that the sugars present in the hydrolysate are effectively utilised by the yeast and fungi.

We can also evaluate the suitability of your process liquids for fermentation and, if necessary, can suggest ways by which they can be detoxified in order to ensure that the sugars present in the hydrolysate are effectively utilised by the yeast and fungi.

Ethanol

There are 3 main types of processes for the fermentation of sugars to bioethanol: 1. Separate hydrolysis and fermentation (SHF); 2. Simultaneous saccharification and fermentation (SSF);

3. Simultaneous saccharification and co-fermentation (SSCF). SHF allows both enzymes and yeast operate at their optimum conditions, but is limited with

product inhibition to enzymes and feed inhibition to yeast. This is overcome in SSF and SSFC fermentation where the enzymatic product glucose

is consumed by yeast as it is produced. High solids loading fermentation with ethanol-tolerant yeast strains allows production of high concentrations of ethanol.

High-solids fermentation causes viscosity issues and hence suitable fermentation regimes and mixers should be designed in order to obtain maximum ethanol concentrations,

yields and productivity.

At Celignis we can use a variety of yeast types to produce bioethanol and can undertake and optimise each of these three main fermentation processes.

At Celignis we can use a variety of yeast types to produce bioethanol and can undertake and optimise each of these three main fermentation processes.

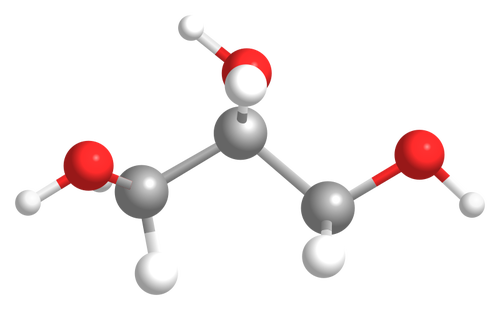

Glycerol

Bio-glycerol is gaining attention due to the consumer demand for non-petroleum derived products and also because of its potential to be a feedstock

for microbial chemicals production (e.g. 1,3 PDO).

We can design processes to produce glycerol in high glucose concentrations using osmo-tolerant yeasts.

We can design processes to produce glycerol in high glucose concentrations using osmo-tolerant yeasts.

Emulsifiers

The type, quality and quantity of emulsifier depends on microbial strain, carbon source, media components such as major and minor elements, temperature, pH etc.

It is important to optimise the process for product quality and quantity. This is only possible with the through understanding of microbial strain, its metabolism and needs.

Our experts can guide you through and optimise the process.

Get in touch with us if you would like further information.

Get in touch with us if you would like further information.

Bacterial Fermentation

Bacteria are mainly used to produce organic acids and alcohols by anaerobic fermentation and enzymes by aerobic fermentation processes.

Very well-known natural fermenters are lactic acid bacteria (LAB) for lactic acid production and Bacillus species such as B. subtilis,

B. amyloliquefaciens, B. licheniformis, B. megaterium etc. for the production of enzymes, antibiotics, surfactins, and biopolymers.

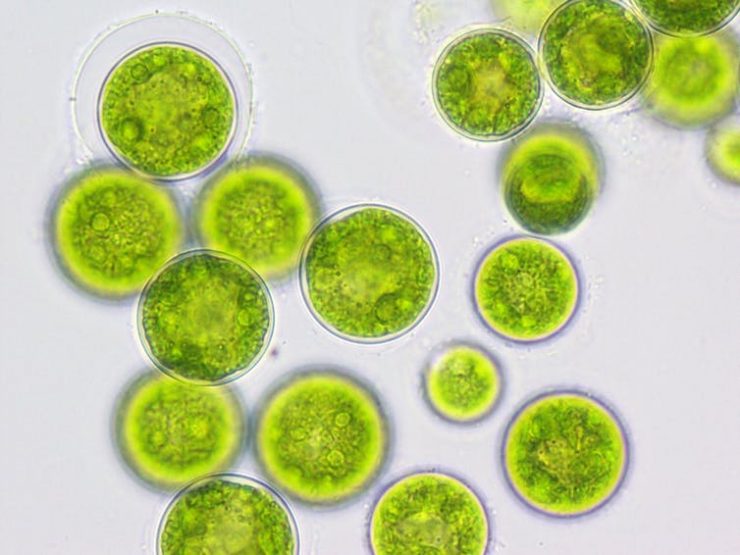

Microalgal Fermentation

Algal cultivation is complicated and requires optimisation to achieve high biomass yields. Algal biomass production depends on nutrient uptake and

other environmental conditions such as temperature, pH, salt concentration etc. It is important to select the strain based on the type of

production (open ponds, photobioreactors), feedstock and application. We have particular expertise in the evaluation and optimisation of algae thorugh

our Chief Innovation Officer, Lalitha, who is currently undertaking a Marie-Curie funded project at Celignis on this topic.

Contact Us For Further Details

We are available to answer any questions you may have on how to get high value chemicals and biofuels from biomass through fermentation processes.

Just get in touch with us by sending us an email info@celignis.com, giving us a call at (+353) 61 371 725, or through

our contact form.