Celignis is now in the USA!

Celignis USA Corp.

We have launched Celignis operations in the US. Our newly-opened facility in Iowa caters for clients across the USA and will offer the same portfolio of services as the lab in Ireland.

We have launched Celignis operations in the US. Our newly-opened facility in Iowa caters for clients across the USA and will offer the same portfolio of services as the lab in Ireland.

We understand the critical role that accurate and timely data plays in the Renewable Natural Gas (RNG) sector. Our wide ranging services cover: Biomethane Potential (BMP) Tests, Continuous Digestions, Toxicity Assays, Microbial Activity Tests, Biological Consultation Services, and Digestate Analysis and Valorisation.

We deliver cutting-edge analysis and consultation services tailored to the biochar sector. Our comprehensive expertise covers feedstock characterisation, process optimisation, biochar properties, and project development. We recognize that understanding and valorising biochar demands in-depth knowledge and experience - and that's exactly what we bring to the table.

We develop and refine processes to efficiently valorise biomass. We can work on individual stages of a process, or develop a bespoke vertically-integrated technology based on your feedstock or target product. This can be done from lab-scale to the 1000-litre level. Our understanding of biomass chemistry, our wide array of bioprocessing equipment, and the biological, engineering, and commercial experience of our team, have resulted in many successful BDS projects to date.

Our techno-economic (TEA) experts can work with you to evaluate the economic prospects of your technology or feedstock. We apply accurate and realistic costing models to determine the CAPEX and OPEX of simulated and pilot scale processes which are then used to determine key economic indicators such as IRR, NPV and payback periods.

Our team has characterised thousands of seaweed samples as well as the products and side-streams of seaweed valorisation processes. Our wide-ranging analysis packages cover: seaweed carbohydrates, amino acids, pigments, phytohormones, vitamins, phenolics, tannins, flavonoids, phlorotannins, and detailed characterisations of the different seaweed polysaccharides, including molecular weight analysis.

We have analysed tens of thousands of samples for their lignocellulosic composition. Such analyses cover feedstocks and the various intermediates, side-streams, and residues of biomass conversion processes. Our reports and insights have helped hundreds of clients effectively scope biomass resources and optimise the efficiency of biorefining technologies. We also offer a low-cost, high-throughput analysis using our proprietary near infrared (NIR) models for lignocellulosic composition.

We can determine the adjusted cellulosic content for any feedstock using approved methods and EPA guidelines. We report the percentage of each component individually, including cellulose, hemicellulose and lignin. Our online Database and Excel and pdf reports also express the adjusted cellulosic content on a dry-ash-free basis so that you can see if the sample meets the 75% threshold or if partial allocation of D3 RINs, based on the proportion, is required.

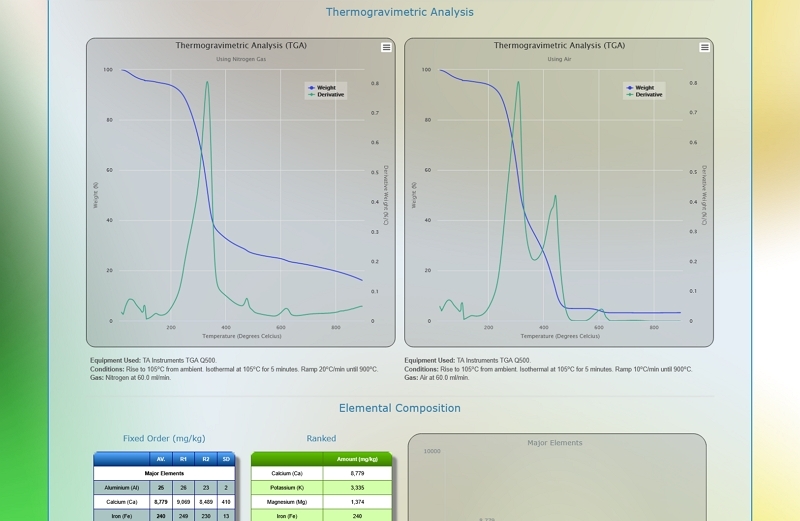

Our laboratories are equipped with a number of state-of-the art items of equipment that allow us to determine the most important combustion-related properties of your biomass including calorific value, volatile matter, elemental composition, moisture content, ash composition and ash melting behaviour.

The Celignis Database is a very popular tool for our clients. It allows for orders to be placed with ease and for results to be viewed as the order progresses. We also provide highly comprehensive Excel and PDF reports upon order completion, with written interpretations of the data in the case of analyses of biomethane potential.

We are home to a growing, talented, and highly motivated team whose expertise spans many important areas of the bioeconomy. We can guide you through our analytical data and suggests the next steps forward. Our team has also played key roles in the formulation, optimisation, and commercial evaluation of biomass valorisation processes in industry and academia and, together, we have the multidisciplinary expertise to evaluate all stages of your bioprocess and suggest real improvements.

Celignis launched in 2014 and has developed an extensive global client base over the years. Our clients include start-ups, multinationals, and world-leading universities. Selected case-studies are given at the link below. Celignis has also been an integral partner in over 20 collaborative research projects, including 8 ongoing projects, and Celignis USA is SAM-registered and eligible to participate in federally-funded projects.

We are a dedicated biomass laboratory whose team of experts provide you with the most precise data, allowing you to make the best use of your biomass feedstocks and optimise your biomass conversion processes.

After 11-years of succesful operations in Ireland, serving over 1,000 clients globally, Celignis is pleased to announce the opening of Celignis laboratories in the USA, operated by Celignis USA Corporation.

"We see huge potential for biomass to sustainably meet global energy and material needs. Through innovation, passion, and determination, we at Celignis strive to make a difference in the development of the bioeconomy."

Daniel Hayes, President of Celignis USA & Founder of Celignis

PhD (Analytical Chemistry)

Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.

PhD

Vision-led and results-driven, Lalitha makes progress tangible. She builds the right alliances, manages complexity with rigor, and delivers outcomes that move the needle.

MAc

Feeds on quality data! Piotr plays a major role in data processing and Orders management at Celignis.

PhD

Our Biomass Detective! Designs, tests, optimizes and validates robust analytical methods for the identification and quantification of functional molecules. Expertise in metabolite profiling, isolation and purification.

PhD

A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.

DipME

Dileep is responsible for the operation of our scaled-up bioprocess in both our private Bioprocess Development Services for clients as well as our numerous ongoing collaborative research projects.

PhD

A key member of the Celignis Bioprocess team. Fernando has been active in the developing polysaccharide fractionation and enzymatic hydrolysis processes.

We provide valued services to over 1000 clients. We understand how feedstocks and technologies can differ regionally and have advised a global network of clients on their bioeconomy projects. We have customs exemptions for samples sent to us, allowing us to quickly get to work no matter where our clients are based.

Biomass is complex. One approach won't work. But with the right mix of composition, technology, and product it can be profitable and sustainable. We're scientists with business brains. Let us help you find the right path.

We know how important your samples are and your need to access data quickly and easily. That's is why we created the Celignis Database where you can view results as the order is ongoing.

Celignis was formed based on research that revolutionised the rapid analysis of advanced biofuel feedstocks. We constantly ask ourselves how things can be done better and what our next revolution will be.

We're delighted to announce that today marks the official launch date of Celignis USA. This latest development in the extension of the Celignis family will offer all of Celignis's services to US-based clients. The 10,000 sq. ft facility is located in Waterloo, Iowa and leverages Celignis's 11 years of expertise in the bioeconomy.

Click here to read more about Celignis USA and our history leading to this point.

Press release accessible at: celignis.com/press_release_2025_11_05.php

We currently offer over 150 analysis packages, covering close to 400 different analytes. We have been proud to provide data to a diverse array of clients over the years, including many from research institutions. A recent literature search found a large number of peer-reviewed articles citing data provided by Celignis. These papers cover our bioprocess development services as well as analytical services across many different sectors (Biorefining, Biochar, Seaweed, Anaerobic Digestion, Bioenergy). Click here to see the details and abstracts of all these publications and here to see the publications that are co-authored by the Celignis team.