Use of Distillation for Downstream Stages in Bioprocesses

Downstream Processing

Downstream-processing in bioprocesses concerns the ways in which output streams (e.g. solid, liquid, slurry etc.) are handled and the means for the recovery and purification of the targeted products. It is a crucial step in bioprocess development that is often overlooked, especially in early stages of research and development, where much of the focus tends to be on optimizing the bioconversion process itself. This is a critical oversight given that downstream processing can account for a large portion (sometimes up to 80%) of the total production costs, particularly in processes dealing with dilute concentrations of the target product or complex mixtures.Importance in Bioprocesses

Giving due focus to downstream processing in bioprocess development can not only lead to better product recovery and quality but also to significant cost savings and improved sustainability. This is especially important in processes concerning the valorisation of lignocellulosic feedstocks, where the complexity of the feedstock and the need for high-purity end products can make the downstream process a significant factor in the overall economic viability of the process.Click below to read more about bioprocess development for downstream processing activities.

Get more info...Downstream Processing

Background

Distillation is a separation technique that exploits differences in the boiling points of the components in a liquid mixture. It is widely used to purify products, concentrate solutions, or remove unwanted compounds in the bioprocessing industry. Examples of its applications include the separation of ethanol from fermentation broth in biofuel production, the isolation of essential oils in the food and flavor industry, and the purification of biochemicals and biopharmaceuticals.Fractional distillation is a special type of distillation used to separate a mixture of two or more substances that have different, but quite close boiling points. This method is often used when the boiling points of the components are so close that simple distillation would not be effective. The setup for fractional distillation includes what is known as a fractionating column, which is a vertical column placed between the boiling flask and the condensing apparatus. The fractionating column is typically filled with glass beads or other materials to provide surface area. When the mixture is heated, the vapor ascends in the fractionating column and condenses on these surfaces. As the condensate drips back down the column, it is reheated by the rising hot vapors and re-vaporizes. This process of condensation and vaporization continues, often referred to as a reflux, and it effectively increases the distance and time the vapor with the higher boiling point must travel, thus providing a better separation of the components.

In comparison, simple distillation, often just referred to as distillation, is best used when trying to separate liquids with boiling points that are significantly different (typically more than 25 degrees Celsius), or when separating liquids from non-volatile solids. In simple distillation, the liquid is heated, producing vapors that are then cooled and collected. The process does not involve a fractionating column.

While both methods have their place in bioprocesses, fractional distillation is typically more energy- and time-consuming due to the additional stages of heating and cooling in the fractionating column. However, it can provide a higher degree of separation, which is crucial in applications where high purity of the product is required.

Important Aspects in Distillation

- Feed Characteristics - The composition and characteristics of the feed have a profound impact on the distillation process. For example, the boiling points and volatility of the components, their compatibility with the chosen distillation method (simple, fractional, or azeotropic), and their potential reactions under distillation conditions should all be considered.

- Process Design - The design of the distillation process, including the type of distillation column, the number of stages, the choice of packing or trays, and the operating conditions, can significantly affect the efficiency and effectiveness of the separation.

- Energy Efficiency - Distillation can be energy-intensive, so it is important to consider strategies for energy conservation, such as heat integration (using the heat from the condensing steam to pre-heat the feed), vapour recompression, or the use of more efficient distillation techniques.

- Product Quality - The desired purity and quality of the product will impact the choice of distillation technique, the degree of separation required, and the operating conditions.

- Environmental Impact - Consideration should be given to the environmental impact of the distillation process, including the emissions and waste generated, as well as the energy use.

- Equipment Costs and Maintenance - The cost of distillation equipment, as well as the costs associated with installation, operation, and maintenance, should be taken into account. This includes considering the lifespan of the equipment and the potential need for replacement or refurbishment.

- Regulatory Compliance - For bioprocesses intended for food, pharmaceutical, or other regulated industries, the distillation process should meet relevant regulatory standards. This includes ensuring product safety, maintaining cleanliness, and providing process validation.

- Integration with Other Processes - The distillation process should be effectively integrated with upstream and downstream processes. For example, the upstream process should generate a feed that is suitable for the distillation process, and the downstream process should be able to handle the product from the distillation process.

Advantages of Distillation

- Efficient Separation - Distillation is highly efficient in separating components in a liquid mixture based on their differences in boiling points. This can result in high-purity products, which is especially beneficial in industries such as pharmaceuticals or fine chemicals where purity is paramount.

- Scalability - Distillation can be scaled up relatively easily, making it a suitable choice for industrial-scale bioprocessing.

- Broad Applicability - Distillation is applicable to a wide range of mixtures, including both organic and inorganic substances. This makes it a versatile tool in bioprocess development.

- Continuous Operation - Distillation processes can often be run continuously, improving productivity and allowing for more stable operating conditions over time.

- Proven Technology - Distillation is a long-established technology with well-understood principles and extensive industry experience. This reduces the risks associated with its implementation.

- Recovery and Reuse - In some cases, distillation allows for the recovery and reuse of solvents or other components, which can improve the sustainability and economics of the process.

- No Chemical Additives - Distillation does not typically require the use of additional chemicals for the separation process, which can be an advantage in terms of safety, cost, and environmental impact.

- Capability of Handling Large Throughput - Distillation columns can process large volumes of feed, providing an advantage for large-scale operations.

- Flexibility - Distillation systems can be designed to handle different feeds and products, providing flexibility in the bioprocess.

Disadvantages of Distillation

- Energy Intensive - Distillation often requires significant amounts of energy, particularly for mixtures with components that have similar boiling points. This can lead to high operational costs and environmental impact.

- Potential Degradation - Certain heat-sensitive products may degrade or undergo unwanted side reactions during distillation, affecting product yield and quality.

- Capital and Maintenance Costs - Distillation equipment, particularly for large-scale processes, can be expensive to purchase, install, and maintain.

- Limited to Volatile Components - Distillation is primarily effective for the separation of volatile components. Non-volatile components, such as salts or certain organic compounds, are not readily separated by distillation.

- Difficulty in Achieving Separation - If the components of the mixture have very similar boiling points, achieving effective separation can be challenging and might require more complex forms of distillation such as fractional or azeotropic distillation.

- Potential for Cross-Contamination - In multi-product processes, there is a risk of cross-contamination unless the system is thoroughly cleaned between batches.

- Environmental Concerns - Emissions of volatile organic compounds (VOCs) can be an environmental concern in some distillation processes.

- Requires Careful Control - Distillation processes require careful control of temperature and pressure to ensure effective separation. This control can sometimes be difficult to maintain, particularly on large scales.

- Risk of Fire and Explosion - Since many solvents are flammable, there can be a risk of fire and explosion with distillation processes, equiring stringent safety measures.

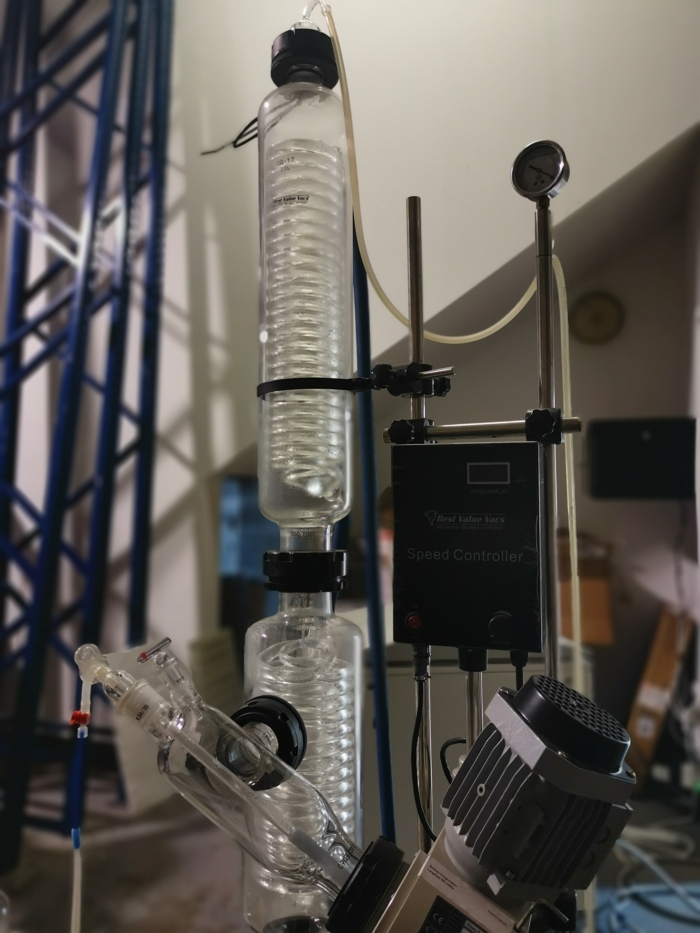

We have different items of distillation equipment in our laboratories. With regards to fractional distillation, we can undertake activities up to TRL4. For simple distillation our capacity is TRL6. Some of the relevant equipment that we have are detailed below.

Buchi R-205 Rotavapor System

The Buchi R-205 Rotavapor System is a high-end lab-scale rotary evaporator recognised for its flexibility and dependability. It has a rotation range from 20 to 280 rpm, an automatic height adjustment feature, and is designed to process samples ranging from 50 mL to 3 L. The system comprises the Buchi B-490 Heating Bath, glassware attachments, Buchi V-500 vacuum pump, and the V-800 vacuum controller.The B-490 heating bath comes with an adjustable temperature scope of 20°C to 180°C, and a temperature accuracy of ±1°C. The Buchi V-805 vacuum controller is capable of reading from 0 to 1400 millibar, and it can regulate from 1 mbar/torr to atmospheric pressure.

The R-205, in conjunction with the V-500 Vacuum pump, can achieve low vacuum levels within minutes. The V-500 can establish a final vacuum of less than 15 mbar, and has a pumping volume of 1.6 cubic meters per hour.

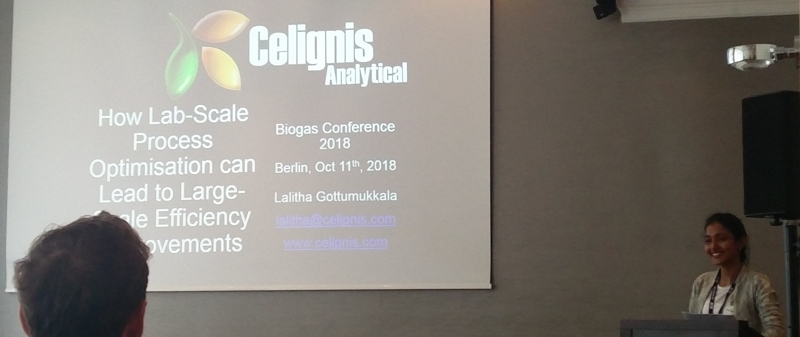

Lalitha Gottumukkala

Founder of Celignis Bioprocess, CIO of Celignis

PhD

<p style="text-align: left;">Has a deep understanding of all biological and chemical aspects of bioproceses. Has developed Celignis into a renowned provider of bioprocess development services to a global network of clients.</p>

Oscar Bedzo

Bioprocess Project Manager & Technoeconomic Analysis Lead

PhD

<p style="text-align: left;">A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.</p>

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

<p style="text-align: left;">Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.</p>