| Programme | CBE-JU, Horizon Europe, HORIZON-JU-CBE-2023-IA-06 |

| Category | Innovation Action (IA) |

| Status | Active |

| Period | 2024 - 2028 |

| Partners | 13 |

| Budget | €9.50m |

| Links | Website, Cordis, CBE-JU, LinkedIn |

BIONEER, is an Innovation Action project funded by the CBE-JU, under topic HORIZON-JU-CBE-2023-IA-06 (Selective, Sustainable Production Routes Towards Bio-Based Alternatives To Fossil-Based Chemical Building Blocks). This project will start in June 2024 with Celignis, an SME partner and full industry BIC member, playing a leading role in the scaled-up (1 m3) production of platform chemicals.

PROMOFER, is an Innovation Action project funded by the CBE-JU, under topic HORIZON-JU-CBE-2023-IA-03 (Improve Fermentation Processes (Including Downstream Purification) To Final Bio-Based Products). This project started in June 2024 with Celignis, an SME partner and full industry BIC member, playing a pivotal role in the project. Our core activities include undertaking the pre-treatment and hydrolysis of lignocellulosic biomass at scaled-up (TRL7, 1 m3) volumes. The resulting sugars are then provided to other partners for downstream fermentations.

MANUREFINERY, is an Innovation Action project funded by the CBE-JU, under topic HORIZON-JU-CBE-2023-IA-01 (Small Scale Biorefining In Rural Areas). This project will start in September 2024 with Celignis, an SME partner and full industry BIC member, involved in the analysis of feedstocks and products of the process. We are also contributing towards the technoeconomic analysis (TEA) of the technologies.

| Programme | CBE-JU, Horizon Europe, HORIZON-JU-CBE-2024-IA-03 |

| Category | Innovation Action (IA) |

| Status | Active |

| Period | 2025 - 2029 |

| Partners | 17 |

| Budget | €9.20m |

| Link | Cordis |

Concens the development of an integrated biorefinery to make a portfolio of bio-based solvents from 2G sugars and furans obtained from spent coffee grounds and woody biomass. Celignis's activities include (i) Design and optimisation of a high-cell-density, two-stage Clostridial process for butanol from hydrolysates; (ii) in-situ solvent recovery via membrane/ extractive set-ups; (iii) enzymatic hydrolysis of both feedstocks.

| Programme | CBE-JU, Horizon Europe, HORIZON-JU-CBE-2024-RIA-01 |

| Category | Research and Innovation Action (RIA) |

| Status | Active |

| Period | 2025 - 2028 |

| Partners | 11 |

| Budget | €3.50m |

| Links | Cordis, CBE-JU |

WoodVALOR valorises contaminated/post-consumer wood waste (WW) via: (i) thermal conversion to biochar; and (ii) fractionation followed by conversions to paints & coatings ingredients. Celignis is involved in Chemo-enzymatic fractionation of decontaminated wood (DW) to sequentially extract/purify lignin and hemicellulose, and in developing hemicellulose-based emulsifiers/stabilizers and binder monomers for industrial formulations. Additionally, Celignis is involved in metals/mineral recovery from decontamination wastewater using biochar produced in the project.

LIGNOFUN funnels lignin streams into high-value aromatics. Celignis leads WP4, putting crude low molecular weight (LMW) lignin through integrated membrane and solvent fractionation into fractions for bioactivity screening (antioxidant, UV-absorbance, antimicrobial, emulsion stabilization), followed by enzymatic/chemical grafting (e.g., sugars, fatty acids) to tune solubility/surface functionality and stability.

Develop and demonstrate bio-based construction products (e.g., wall panels, flooring tiles, sandwich structures). Celignis leads materials development: chemo-enzymatic extraction and fractionation of lignin/xylan/cellulose from agri/forest residues, followed by advanced chemical modification of xylan and lignin (mixed-molecule grafting, acylation and silylation) to tailor hydrophobicity, flow/rheology (via DP control), mechanical strength, and fire resistance for injection-moulding/3D-printing.

| Programme | CBE-JU, Horizon Europe, BBI-2020-SO3-R5 |

| Category | Research and Innovation Action (RIA) |

| Status | Completed |

| Period | 2021 - 2024 |

| Partners | 13 |

| Budget | €6.25m |

| Links | Website, Cordis, CBE-JU |

| Programme | CBE-JU, Horizon Europe, BBI.R10-2015 |

| Category | Research and Innovation Action (RIA) |

| Status | Completed |

| Period | 2016 - 2019 |

| Partners | 11 |

| Budget | €3.77m |

| Links | Website, Cordis, CBE-JU, Twitter |

| Programme | CBE-JU, Horizon Europe, BBI.2017.R2 |

| Category | Research and Innovation Action (RIA) |

| Status | Completed |

| Period | 2018 - 2022 |

| Partners | 13 |

| Budget | €3.72m |

| Links | Website, Cordis, CBE-JU, Twitter, LinkedIn, Facebook |

| Programme | CBE-JU, Horizon Europe, BBI.2018.SO2.D3 |

| Category | Innovation Action (IA) |

| Status | Completed |

| Period | 2019 - 2023 |

| Partners | 11 |

| Budget | €13.70m |

| Links | Website, Cordis, CBE-JU, Twitter |

Extraction of Hemicellulose Polysaccharides

| Related Projects | ||||

|

|

|

||

Modification of Polysaccharides

| Related Projects | |||

|

|

|

|

Identification, Extraction, and Purification of High Value Chemicals in Biomass

| Related Projects | |

|

|

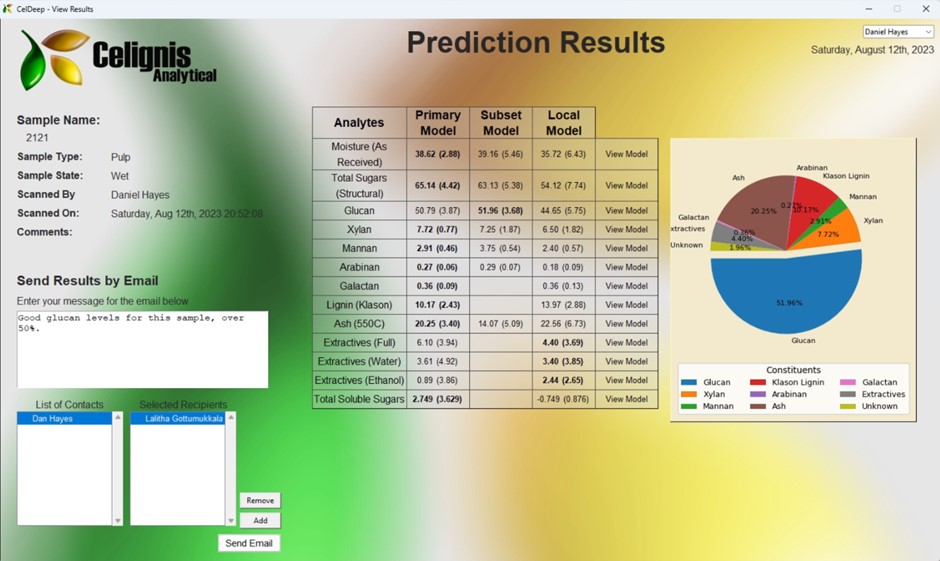

Real-Time Analysis of Feedstocks and Process Outputs

| Related Projects | |||

|

|

|

|

Compositional Analysis

| Related Projects | ||||

|

|

| ||

Fermentation Optimisation

| Related Projects | |

|

|

Discovery and Use of Enzymes

| Related Projects | ||||

|

|

|

| |

Anaerobic Digestion and Fermentation

| Related Projects | |

|

|

Biomass Pretreatment and Fractionation

| Related Projects | ||||

|

|

|

|

|

Process Flow Diagrams and Techno-Economic Analysis of the Process

| Related Projects | |

|

|

Successful Proposal Writing and Proposal Evaluation

| Successful EU Proposals Primarily Written By Celignis Personnel | |||

|

|

|

|

Click here to see our pitches for specific roles in some of the 2024 topics.

Go Back to Research Projects page.

Celignis's Oscar and Fernando are today attending the 12-month review meeting of our CBE-JU research project MANUREFINERY. The event is taking place at the facility of project partner ENCO in Naples, Italy.

MANUREFINERY, entitled "Smart modular mobile biorefining of manure to zero-waste maximising resource recovery for feed and fertiliser bioingredients in rural areas" is one of the 7 ongoing CBE-JU projects that Celignis is currently involved in. Click here to read more about these projects.

Today the Celignis family welcomed Dileep Raveendran-Nair to the fold. Dileep is a Mechanical Engineer with over 11 years of hands-on experience in biofuel, biochar, and bioproduct process engineering. His career has focused on the operation, maintenance, and optimization of large-scale bioprocess and bioenergy systems, integrating engineering precision with biotechnological innovation to advance sustainable industrial application.

At Celignis he will play a key-role ("Mechanical Engineer for Scaled-up Bioprocesses") in the development of our bioprocessing capabilities as we increase the Technology Readiness Levels (TRL) of our bioprocessing facility to TRL7 and cubic-metre reactors.

Dileep will be involved in the development and implementation of Bioprocess Development Services for our clients and in the scaled-up bioprocessing activities in our numerous ongoing research projects. Additionally, Dileep will take the lead in Celignis's Biochar Production services for our clients.

We are delighted to announce that Celignis has been successful in 4 project proposals submitted for funding to the Circular Bio-based Europe Joint Undertaking (CBE JU) programme.

These projects will provide funding of 1.6m EUR to Celignis over the next few years and build upon the 3 projects (worth 1.5m EUR) we secured last year and the 4 previous CBE/BBI projects that Celignis participated in.

Details on the projects are provided below:

WoodVALOR - This RIA project concerns the valorisation of contaminated/post-consumer wood waste (WW) via: (i) thermal conversion to biochar; and (ii) fractionation followed by conversions to paints & coatings ingredients. Celignis is involved in the chemo-enzymatic fractionation of decontaminated wood (DW) to sequentially extract/purify lignin and hemicellulose, and in developing hemicellulose-based emulsifiers/stabilizers and binder monomers for industrial formulations. Additionally, Celignis is involved in metals/mineral recovery from decontamination wastewater using biochar produced in the project.

SOLRESS - This Innovation Action (TRL6) project concens the development of an integrated biorefinery to make a portfolio of bio-based solvents from 2G sugars and furans obtained from spent coffee grounds and woody biomass. Celignis's activities include (i) Design and optimisation of a high-cell-density, two-stage Clostridial process for butanol from hydrolysates; (ii) in-situ solvent recovery via membrane/ extractive set-ups; (iii) enzymatic hydrolysis of both feedstocks.

BIOS MATER - Also an Innovation Action (IA) project, BIOS MATER targets the development and demonstration of bio-based construction products (e.g., wall panels, flooring tiles, sandwich structures). Celignis leads materials development: chemo-enzymatic extraction and fractionation of lignin/xylan/cellulose from agri/forest residues, followed by advanced chemical modification of xylan and lignin (mixed-molecule grafting, acylation and silylation) to tailor hydrophobicity, flow/rheology (via DP control), mechanical strength, and fire resistance for injection-moulding/3D-printing.

LIGNOFUN - This IA project funnels lignin streams into high-value aromatics. Celignis leads WP4, putting crude low molecular weight (LMW) lignin through integrated membrane and solvent fractionation into fractions for bioactivity screening (antioxidant, UV-absorbance, antimicrobial, emulsion stabilization), followed by enzymatic/chemical grafting (e.g., sugars, fatty acids) to tune solubility/surface functionality and stability.

Celignis is a Full Industry Member of the Biobased Industries Consortium (BIC), which helps to steer the focus of research for the CBE-JU programme.

Click here to read about all of our current research projects and here to read about our completed research projects.

Celignis personnel are today attending the kick-off meeting of the CBE-JU project MANUREFINERY at the facilities of the project's coordinator (ITA) in Zaragoza, Spain.

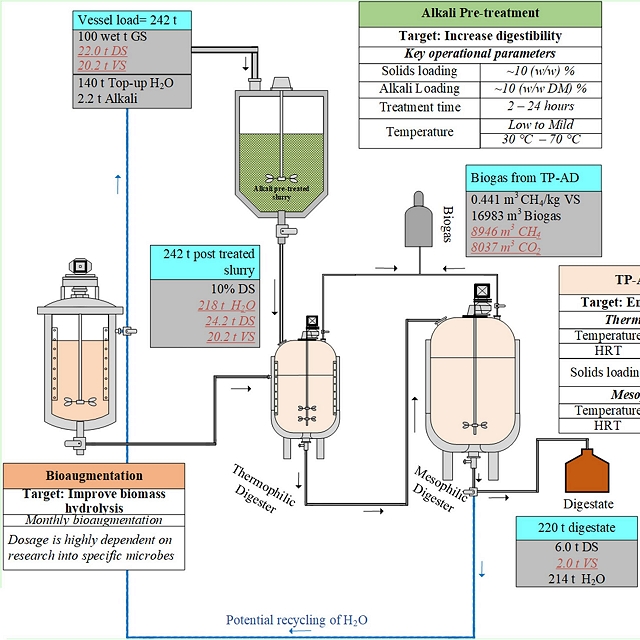

MANUREFINERY concerns the development of a small, decentralised, modular biorefinery concept for farms that converts manure and ammonia emissions into seven marketable bio-ingredients (animal-feed proteins, caproic acid, and fertiliser salts/ashes). The solution integrates fixed/mobile units across three valorisation lines (gas, liquid, solid) and a digital twin for optimisation and scale-up, targeting TRL6-7 validation on four EU demo farms.

Celignis has a number of key roles in the project, including:

- Comprehensive analysis of the feedstocks and products of the process.

- Technoeconomic analysis for the three valorisation lines.

- Development of an extraction technology for grass.

PROMOFER, is an Innovation Action project funded by the CBE-JU, under topic HORIZON-JU-CBE-2023-IA-03 (Improve Fermentation Processes (Including Downstream Purification) To Final Bio-Based Products).

This project started in June 2024 with Celignis, an SME partner and full industry BIC member, playing a pivotal role in the project. Our core activities include undertaking the pre-treatment and hydrolysis of lignocellulosic biomass at scaled-up (TRL7, 1 m3) volumes. The resulting sugars are then provided to other partners for downstream fermentations.

Today Celignis's CIO Lalitha is attending the kick-off meeting of the project, at coordinator AIMPLAS's headquarters in Valencia, Spain.

Lalitha is attending the kick-off meeting of our CBE-JU project BIONEER, located at the coordinator's (SINTEF) premises in Trondheim, Norway.

BIONEER has the title "Scaled-up Production of Next-Generation Carbohydrate-Derived Building Blocks to Enhance the Competitiveness of a Sustainable European Chemicals Industry". It is a 4-year Innovation Action project with 7.5m EUR of funding provided by the CBE-JU.

Celignis plays a key role in BIONEER, being responsible for the scaled-up (TRL7) production of platform chemicals.

Today a new publication, covering results obtained in the VAMOS project, funded by the CBE-JU, has been published online.

This publication includes results of Celignis's analyses of project-dervived samples and also covers the use of the waste pulp for the production of composites.

Details of the paper are provided below:

Herrera, N., Ordóñez, D. F., Gaduan, A. N., Singkronart, K., Hayes, D., Puri, D., Lee, K.-Y. (2024) Valorisation of waste pulp from materials recovery facility rejects for composite applications, Composites Part A: Applied Science and Manufacturing 180: 108108

Click here to view the full publication.

We are pleased to announce that three of the proposals involving Celignis, submitted to the CBE-JU programme for funding collaborative biomass research in Europe, were successful. These projects will provide an additional funding of €1.5m to Celignis and build on our achievements in other CBE and EU projects. In particular, the projects are all at enhanced TRLs (6/7) and will use our existing Celignis Bioprocess infrastructure and will also fund further development of our bioprocessing capacities and the Bioprocess Development Services we offer our clients.

Details on the funded projects are provided below:

BIONEER - This project was funded under CBE-JU topic IA-06 and focuses on the TRL 6/7 production of biobased platform chemicals. Celignis's activities in the project focus on scaling up the work undertaken in our ongoing CBE-JU RIA project PERFECOAT and the Cluster 6 Horizon Europe project EnxylaScope.

PROMOFER - This project was funded under CBE-JU topic IA-03 and focuses on scaling up improved fermentation processes. Celignis's activities in the project are focused on the TRL7 (1m3 reactor) production of fermentable carbohydrates from lignocellulosic feedstocks.

MANUREFINERY - This project was funded under CBE-JU topic IA-01 and focuses on demonstrating small scale biorefining in rural areas. Celignis will be responsible for undertaking technoeconomic analyses of the integrated processes for valorising agricultural side-streams.

Celignis is a Full Industry Member of the Biobased Industries Consortium (BIC), which helps to steer the focus of research for the CBE-JU programme. On Feb 8th Celignis's Dan Hayes, Lalitha Gottumukkala, and Oscar Bedzo will be attending a BIC networking event in Brussels where we will discuss collaborations in the research programme topics recently announced for 2024.

The Circular Bioeconomy Europe Joint Undertaking (CBE-JU) is an organisation that funds biomass research in Europe at various Technology Readiness Levels (TRLs). Since 2016 Celignis has been an active participant in a number of projects funded by the CBE-JU.

The Biobased Industries Consortium (BIC) is the steering committee that helps to steer the focus of research for the CBE-JU programme. In 2023 Celignis joined the BIC as a Full Industry Member and participated in several proposals submitted for different research topics in the CBE-JU's 2023 Work Programme.

On Feb 8th Celignis's Dan Hayes, Lalitha Gottumukkala, and Oscar Bedzo will be attending a BIC networking event in Brussels where we will discuss potential collaborations in the research programme topics recently announced for 2024.

If you are also attending that event then please get in touch with us, either through the Celignis website or via the event's networking platform, so that we can discuss potential synergies in proposals for the 2024 topics.

| Celignis's BBI/CBE Projects | |||

|

|

|

|

|  |  |