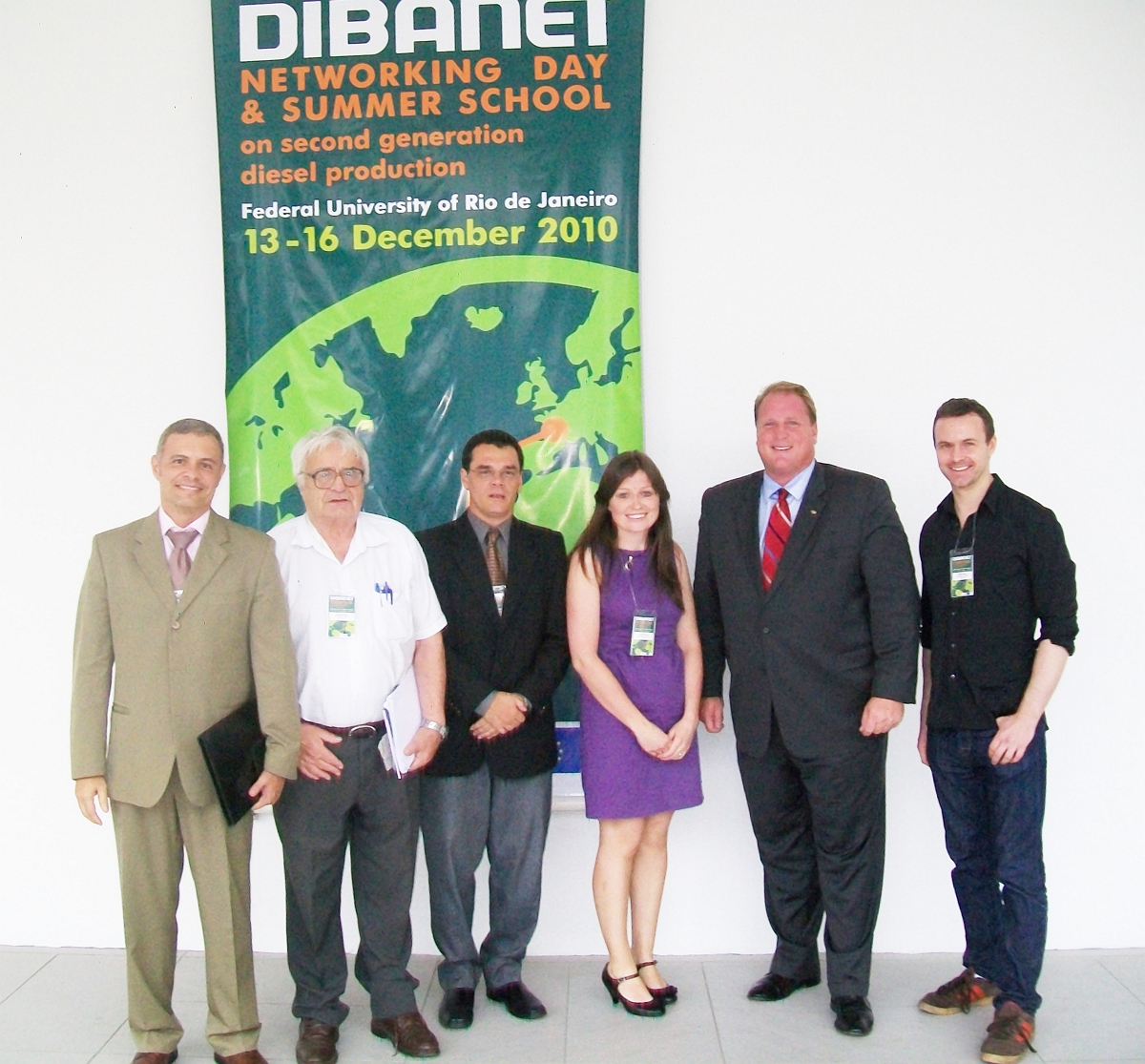

DIBANET

DIBANET

"The Production of Sustainable Diesel-Miscible-Biofuels from the Residues and Wastes of Europe and Latin America"

| Programme | Horizon Europe, FP7.ENERGY.2008.3.2.1 |

| Category | Research and Innovation Action (RIA) |

| Status | Completed |

| Period | 2009 - 2013 |

| Partners | 14 |

| Budget | €3.73m |

| Links | Website, Cordis |

The particular focus of the project was on the production of levulinic acid (a valuable platform chemical), from cellulose and hexose sugars, and of furfural from hemicellulose-dervied pentose sugars such as xylose. The process employed acid-hydrolysis, at elevated temperatures and pressures, to hydrolyse the polsyaccharides and produce the targeted molecules. The project also involved the development of a novel pre-treatment process, employing formic acid and hydrogen peroxide. The solid residues that were retained after hydrolysis were pyrolysed and gasified in order to produce energy.

Dan's primary scientific role in the project was in WP2 where he led efforts to generate algorithms for the prediction of biomass composition based on the near infrared spectra of samples, which can be collected in a matter of seconds versus the days/weeks required for chemical analysis methods. Particular focuses for model development in DIBANET were the feedstocks Miscanthus (highly suitable for European climates) and sugarcane bagasse (a highly abundant fibrous residue resulting from the extraction of sucrose from sugar cane, grown in large quantities in Brazil and other Latin American countries).

The development of the rapid biomass analysis models in DIBANET resulted in Dan spinning-out Celignis in 2014.

Miscanthus plants were sampled from several plantations in Ireland over the harvest window (October-April). These were separated into their anatomical components and the loss of leaves monitored. Three distinct phases were apparent: there was minimal loss in the "Early" (October to early December) and "Late" (March and April) phases, and rapid leaf loss in the interim period. Samples were analysed for constituents relevant to biorefining. Changes in whole-plant composition included increases in glucose and Klason lignin contents and decreases in ash and arabinose contents. These changes arose mostly from the loss of leaves, but there were some changes over time within the harvestable plant components. Although leaves yield less biofuel than stems, the added biomass provided by an early harvest (31.9-38.4%) meant that per hectare biofuel yields were significantly greater (up to 29.3%) than in a late harvest. These yields greatly exceed those from first generation feedstocks. | |

There has been a significant degree of hype regarding the commercial potential of second-generation biofuels (2GBs; biofuels sourced from lignocellulosic materials). In 2007, ambitious targets for the mass substitution of fossil-fuel-derived transport fuels by 2GBs were put forward in the United States and similar targets exist for other countries. However, as of May 2012, no commercial-scale 2GB facilities are currently operating. The technical and financial obstacles that have delayed the deployment of these facilities are discussed, as are recent advancements in research that may help to overcome some of these. There are six commercial-scale facilities currently (May, 2012) in construction and many more are planned in the near term. The prospects for 2GBs are more promising now than in the past but the delays in getting to this point mean that the ambitious targets of several years ago are unlikely to be reached in the near term. | |

Biomass feedstocks for the production of biofuels and chemicals vary greatly in their chemical compositions. These differences affect which technologies are used for processing. First generation technologies focus on the conversion of sugars, starches, and oils whilst second generation technologies process lignocellulose. While the conversion in first generation processes is relatively facile, the processing of lignocellulose is hindered by the complexity of the biomass matrix. Lignocellulosic feedstocks, however, tend to be significantly less costly, in economic, environmental, and energy terms, to produce. The effects of the various constituents on the conversion of biomass by either hydrolytic or thermochemical means are discussed, as are the logistical considerations needed when sourcing feedstocks. Biomass can be classified as a specifically grown energy crop, an agricultural residue, or a waste resource. Several examples of lignocellulosic feedstocks are discussed for each of these types and representative chemical data for a variety of materials presented. | |

The DIBANET process chain, as a result of its patented pre-treatment stage, has significantly increased the yields of levulinic acid, formic acid, and furfural beyond what was considered to be the state of the art. By fractionating lignocellulosic biomass into its three main polymers (cellulose, hemicellulose, lignin) it has also allowed for lignin to be recovered and sold as a higher-value product. These developments have meant that the amount of acid hydrolysis residues (AHRs) that have been produced are significantly (up to 88%) less than in the Biofine process. These AHRs are required to provide process heat for DIBANET. Direct combustion is the most efficient means for doing this. If such combustion does not occur and the AHRs are instead used in other processes, e.g. pyrolysis and gasification, then more biomass will need to be purchased to fuel the core DIBANET process. The AHRs have not been proven to be superior to virgin biomass when put through these thermochemical processes. Indeed, many of the results from DIBANET Work Package 4 indicate the opposite. Hence, given that DIBANET, and the modelling of its optimal configuration, is designed on the basis of an integrated process, centred on the core element of the acid hydrolysis of biomass, then combustion is the only viable end use for the AHRs.

| ||

Miscanthus samples were scanned over the visible and near infrared wavelengths at several stages of processing (wet-chopped, air-dried, dried and ground, and dried and sieved). Models were developed to predict lignocellulosic and elemental constituents based on these spectra. The dry and sieved scans gave the most accurate models; however the wet-chopped models for glucose, xylose, and Klason lignin provided excellent accuracies with root mean square error of predictions of 1.27%, 0.54%, and 0.93%, respectively. These models can be suitable for most applications. The wet models for arabinose, Klason lignin, acid soluble lignin, ash, extractives, rhamnose, acid insoluble residue, and nitrogen tended to have lower R(2) values (0.80+) for the validation sets and the wet models for galactose, mannose, and acid insoluble ash were less accurate, only having value for rough sample screening. This research shows the potential for online analysis at biorefineries for the major lignocellulosic constituents of interest. | |

This document is the result of the evaluation of biomass feedstocks, from Europe and Latin America, that took place as part of the DIBANET project. That project is co-financed from the 7 th Framework Programme for Research and Technological Demonstration of the European Union. (Title: Enhancing international cooperation between the EU and Latin America in the field of biofuels; Grant Agreement No: 227248-2).

| |||

The processing of lignocellulosic materials in modern biorefineries will allow for the

production of transport fuels and platform chemicals that could replace petroleum-derived

products. However, there is a critical lack of relevant detailed compositional information

regarding feedstocks relevant to Ireland and Irish conditions. This research has involved the

collection, preparation, and the analysis, with a high level of precision and accuracy, of a

large number of biomass samples from the waste and agricultural sectors. Not all of the

waste materials analysed are considered suitable for biorefining; for example the total sugar

contents of spent mushroom composts are too low. However, the waste paper/cardboard

that is currently exported from Ireland has a chemical composition that could result in high

biorefinery yields and so could make a significant contribution to Irelandís biofuel demands. | ||

Other Celignis Research Projects Funded by the Horizon Programme

Current Projects

|

|

|

|

|

|

| ||

| Enxylascope aims at bioprospecting and producing a novel set of xylan debranching enzymes, thereby demonstrating its ability to make xylan a key ingredient in a variety of consumer products. Celignis is playing a key role, being the technical lead and responsible for the extraction and modification of xylan from biomass. Further info...PERFECOAT, a RIA project funded by the BBI JU, targets the development of novel sustainable coatings that will ultimately be available to the public. Celignis is responsible for the extraction and modification of polymers (xylan and chitosan) that will be used as binders in these coatings. Further info...BIONEER, is an Innovation Action project funded by the CBE-JU, under topic HORIZON-JU-CBE-2023-IA-06 (Selective, Sustainable Production Routes Towards Bio-Based Alternatives To Fossil-Based Chemical Building Blocks). This project will start in May 2024 with Celignis, an SME partner and full industry BIC member, playing a leading role in the scaled-up (1 m3) production of platform chemicals. Further info...PROMOFER, is an Innovation Action project funded by the CBE-JU, under topic HORIZON-JU-CBE-2023-IA-03 (Improve Fermentation Processes (Including Downstream Purification) To Final Bio-Based Products). This project will start in June 2024 with Celignis, an SME partner and full industry BIC member, playing a pivotal role in the project. Our core activities include undertaking the pre-treatment and hydrolysis of lignocellulosic biomass at scaled-up (TRL7, 1 m3) volumes. The resulting sugars are then provided to other partners for downstream fermentations. Further info...MANUREFINERY, is an Innovation Action project funded by the CBE-JU, under topic HORIZON-JU-CBE-2023-IA-01 (Small Scale Biorefining In Rural Areas). This project will start in September 2024 with Celignis, an SME partner and full industry BIC member, involved in the analysis of feedstocks and products of the process. We are also contributing towards the technoeconomic analysis (TEA) of the technologies. Further info...This demo project involves innovative superheated steam processing of unwanted bush and invasive biomass into high-value, clean-burning, low-cost solid biofuel. Celignis will analyse feedstocks, and process outputs, and use our QTOF-LC/MS system to profile the steam condensate for high value chemicals. We will then develop a method to recover target constituents. Further info...BIO4AFRICA will empower smallholder farmers by creating value from locally available biomass. Celignis is analysing a wide range of biomass feedstocks, from a number of African countries, and providing recommendations regarding the most suitable ones, under the best conditions, for the given processing technology. We also analyse the outputs of the various processes. Further info... |

|

|

Completed Projects

|

|

|

|

|

|

| The BIOrescue project was focused on developing technologies to convert spent mushroom compost, a problematic waste of the mushroom industry, to high value products. Within the project Celignis undertook a compositional profiling study of the feedstocks and developed rapid analysis models for these and process outputs. Further info...The UNRAVEL project (UNique Refinery Approach to Valorise European Lignocellulosics) is focused on the optimsiation of a biomass pre-treatment technology. Celignis plays a key role by analysing and evaluating the extractives present in a wide variety of feedstocks and determining how they influence pre-treatment. Further info...The focus of ENABLING was on supporting the spreading of best practices and innovation in the provision of biomass for the Bio-Based Industry (BBI). Celignis played a key role in the project with regards to stressing the importance of biomass composition in terms of evaluating feedstock and technology suitability. Further info...Celignis was the sole partner in SAPHIRE. The project, funded by the European Union's INNOSUP programme, concerned the production of high-value hydrogels from lignocellulosic residues. These are expected to have applications in the cosmetic and pharmaceutical sectors. Further info...VAMOS concerns the construction and operation of a demonstration-scale biorefinery producing lactic acid from the paper fraction of municipal waste. In the project Celignis will develop custom NIR models for the rapid at-line on-site analysis of the feedstock and process outputs. Further info...This was a Marie-Curie Individual Fellowship (MCSA-IF) involving Celignis's Lalitha in which algae were used to recover nutrients from anaerobic digestion (AD) process streams. Further info... |

|

|

Other Celignis Research Projects

Current Projects

| ||

| Celignis is the sole partner in STEAME, a project funded by the Irish Research Council and focused on the development of technologies to make anaerobic digestion more financially viable in Ireland. Further info... |

|

|