ALGALVANISE

ALGALVANISE

"ALGAL biorefinery of biogas digestate to high VAlue fuNctional IngredientS through circular approachEs"

| Programme | Horizon Europe, H2020-EU.1.3.2 |

| Category | Marie Curie IF |

| Status | Completed |

| Period | 2020 - 2022 |

| Partners | 1 |

| Budget | €0.18m |

| Link | Cordis |

The ALGALVANISE project was designed to add an additional revenue stream to the biogas plants by producing high value products and reducing the disposal problems with the digestate. Digestate is rich in phosphates and nitrogen and also contains substantial amounts of organic content that is not converted to biomethane.

The richness of digestate in nutrients and organic matter makes it a suitable feed for biotransformation (fungal, algal, or bacterial) to high value products.

Algal cultivation is favoured over fungal and bacterial systems for wastewater or digestate treatment due to the ability of algae to assimilate nutrients and produce high-value products including proteins, lipids and natural pigments. Microalgae and cyanobacteria can also accumulate phosphorous as polyphosphates to use it under phosphorous-limited conditions. This luxury uptake mechanism can allow them to sequester more nutrients, a clear advantage for digestate nutrient recovery systems.

Algal cultivation is favoured over fungal and bacterial systems for wastewater or digestate treatment due to the ability of algae to assimilate nutrients and produce high-value products including proteins, lipids and natural pigments. Microalgae and cyanobacteria can also accumulate phosphorous as polyphosphates to use it under phosphorous-limited conditions. This luxury uptake mechanism can allow them to sequester more nutrients, a clear advantage for digestate nutrient recovery systems.

In the integration of algal cultivation at an AD facility, a natural consortium of bacteria and algae can be established based on the composition of the digestate and environmental/process conditions.

The ALGALVANISE project has advanced the state-of-the art by developing a series of innovative solutions for separate applications in the biogas and algae industries as well as the best integrated solution for a

biogas-algae biorefinery. This concept hybrid system has the following features and benefits:

1. The algae-bacteria consortium has established into robust system that produces a variety of high-value products such as pigments, proteins and lipids from digestate.

2. Mixed algae-bacteria consortium that does not require an expensive sterilization process to grow the algae.

3. The effluent from biogas-algae biorefinery is clean and low in nutrients.

4. Optimised process conditions for the production of pigments, proteins and lipids by algae and chitosan dosage for flocculation of bacteria-algae mixed culture.

5. Production of a mix of pigments with high bioactive potential.

1. The algae-bacteria consortium has established into robust system that produces a variety of high-value products such as pigments, proteins and lipids from digestate.

2. Mixed algae-bacteria consortium that does not require an expensive sterilization process to grow the algae.

3. The effluent from biogas-algae biorefinery is clean and low in nutrients.

4. Optimised process conditions for the production of pigments, proteins and lipids by algae and chitosan dosage for flocculation of bacteria-algae mixed culture.

5. Production of a mix of pigments with high bioactive potential.

This project has received funding from the European Union's Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement No 898560.

Other Celignis Research Projects Funded by the Horizon Programme

Current Projects

|

|

|

|

|

|

| ||

| Enxylascope aims at bioprospecting and producing a novel set of xylan debranching enzymes, thereby demonstrating its ability to make xylan a key ingredient in a variety of consumer products. Celignis is playing a key role, being the technical lead and responsible for the extraction and modification of xylan from biomass. Further info...PERFECOAT, a RIA project funded by the BBI JU, targets the development of novel sustainable coatings that will ultimately be available to the public. Celignis is responsible for the extraction and modification of polymers (xylan and chitosan) that will be used as binders in these coatings. Further info...BIONEER, is an Innovation Action project funded by the CBE-JU, under topic HORIZON-JU-CBE-2023-IA-06 (Selective, Sustainable Production Routes Towards Bio-Based Alternatives To Fossil-Based Chemical Building Blocks). This project will start in May 2024 with Celignis, an SME partner and full industry BIC member, playing a leading role in the scaled-up (1 m3) production of platform chemicals. Further info...PROMOFER, is an Innovation Action project funded by the CBE-JU, under topic HORIZON-JU-CBE-2023-IA-03 (Improve Fermentation Processes (Including Downstream Purification) To Final Bio-Based Products). This project will start in June 2024 with Celignis, an SME partner and full industry BIC member, playing a pivotal role in the project. Our core activities include undertaking the pre-treatment and hydrolysis of lignocellulosic biomass at scaled-up (TRL7, 1 m3) volumes. The resulting sugars are then provided to other partners for downstream fermentations. Further info...MANUREFINERY, is an Innovation Action project funded by the CBE-JU, under topic HORIZON-JU-CBE-2023-IA-01 (Small Scale Biorefining In Rural Areas). This project will start in September 2024 with Celignis, an SME partner and full industry BIC member, involved in the analysis of feedstocks and products of the process. We are also contributing towards the technoeconomic analysis (TEA) of the technologies. Further info...This demo project involves innovative superheated steam processing of unwanted bush and invasive biomass into high-value, clean-burning, low-cost solid biofuel. Celignis will analyse feedstocks, and process outputs, and use our QTOF-LC/MS system to profile the steam condensate for high value chemicals. We will then develop a method to recover target constituents. Further info...BIO4AFRICA will empower smallholder farmers by creating value from locally available biomass. Celignis is analysing a wide range of biomass feedstocks, from a number of African countries, and providing recommendations regarding the most suitable ones, under the best conditions, for the given processing technology. We also analyse the outputs of the various processes. Further info... |

|

|

Completed Projects

|

|

|

|

|

|

| DIBANET was an FP7 research project, written and coordinated by Celignis founder Dan Hayes, that concerned the production of second generation biofuels from biomass feedstocks in Europe and Latin America. The advances in the state of the art of biomass analysis made in DIBANET led to the formation of Celignis. Further info...The BIOrescue project was focused on developing technologies to convert spent mushroom compost, a problematic waste of the mushroom industry, to high value products. Within the project Celignis undertook a compositional profiling study of the feedstocks and developed rapid analysis models for these and process outputs. Further info...The UNRAVEL project (UNique Refinery Approach to Valorise European Lignocellulosics) is focused on the optimsiation of a biomass pre-treatment technology. Celignis plays a key role by analysing and evaluating the extractives present in a wide variety of feedstocks and determining how they influence pre-treatment. Further info...The focus of ENABLING was on supporting the spreading of best practices and innovation in the provision of biomass for the Bio-Based Industry (BBI). Celignis played a key role in the project with regards to stressing the importance of biomass composition in terms of evaluating feedstock and technology suitability. Further info...Celignis was the sole partner in SAPHIRE. The project, funded by the European Union's INNOSUP programme, concerned the production of high-value hydrogels from lignocellulosic residues. These are expected to have applications in the cosmetic and pharmaceutical sectors. Further info...VAMOS concerns the construction and operation of a demonstration-scale biorefinery producing lactic acid from the paper fraction of municipal waste. In the project Celignis will develop custom NIR models for the rapid at-line on-site analysis of the feedstock and process outputs. Further info... |

|

|

Other Celignis Research Projects

Current Projects

| ||

| Celignis is the sole partner in STEAME, a project funded by the Irish Research Council and focused on the development of technologies to make anaerobic digestion more financially viable in Ireland. Further info... |

|

|

September 14th 2021

ALGALVANISE - Astaxanthin Extracted from Microalgae!

High value constituent successfully extracted

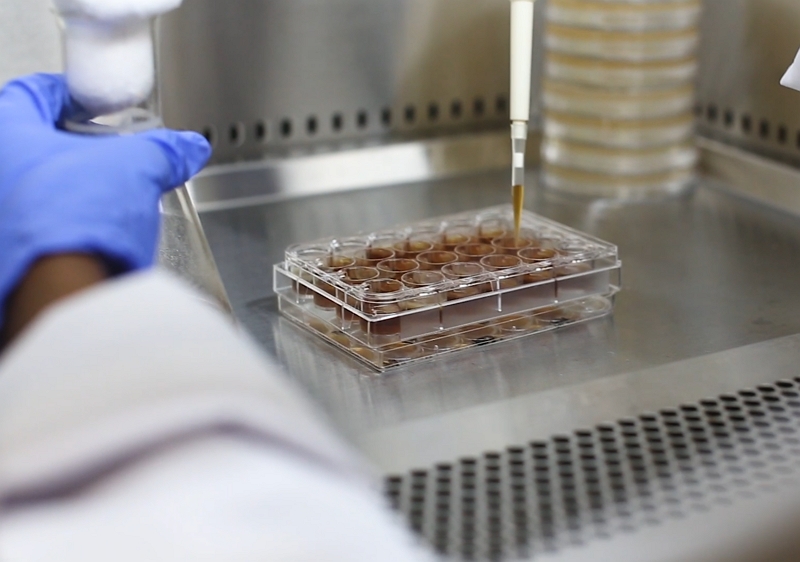

Below is included an image of the solvent extract, containing the valuable pigment astaxanthin, obtained from microalgae that has been cultured and grown in our ALGALVANISE project. This output demonstrates successful achievement of a primary objective of Lalitha's project, that high value compounds can be obtained from algae that utilise waste streams from the anaerobic digestion sector as a nutrient and growth source.

June 19th 2021

ALGALVANISE - Algae Flocculation with Chitosan

We are pleased to report that we have succesfully achieved another project target!

The image below shows the successful flocculation of algae by using chitosan. This was one of the key objectives of the ALGALVANISE project that involve's Celignis's Lalitha.

Traditionally, algal harvesting costs can comprise around 30% of the total operating costs of lage plants, hence reducing these will have a major positive effect on algal cultivation economics. Modern separators use 0.4 kWh/m3, a high energy requirement given average algal biomass concentration is only 1g/L. For separation to give a positive energy balance the energy required for harvesting needs to be reduced to 0.1 kWh/m3. ALGALVANISE targets such a low energy system through the use of coagulation/flocculation methods with the use of chitosan being one of these approaches.

Further work will be undertaken to optimise the process in order to find the minimum chitosan dosage to enhance bacterial flocculation in terms of yield and quality of the biomass without using any alkali agents.

Traditionally, algal harvesting costs can comprise around 30% of the total operating costs of lage plants, hence reducing these will have a major positive effect on algal cultivation economics. Modern separators use 0.4 kWh/m3, a high energy requirement given average algal biomass concentration is only 1g/L. For separation to give a positive energy balance the energy required for harvesting needs to be reduced to 0.1 kWh/m3. ALGALVANISE targets such a low energy system through the use of coagulation/flocculation methods with the use of chitosan being one of these approaches.

Further work will be undertaken to optimise the process in order to find the minimum chitosan dosage to enhance bacterial flocculation in terms of yield and quality of the biomass without using any alkali agents.

September 28th 2020

ALGALVANISE - Filamentous Microalgae Isolated

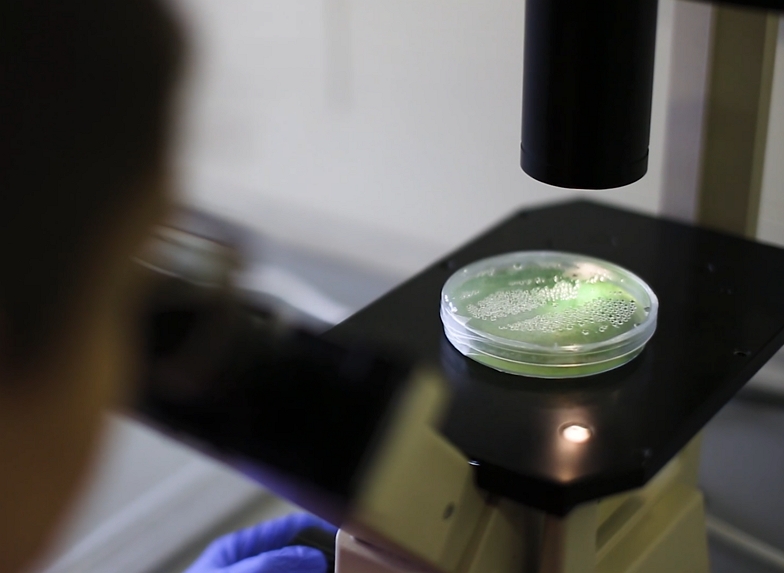

Check out a video of our algae strain isolated in the project

Below is a short video of the microscope-view (10X) of a filamentous microalgae strain that we have isolated as part of the ALGALVANISE project involving Celignis's Lalitha.

April 1st 2020

Kick-off of ALGALVANISE PROJECT

We are happy to announe the start of our innovative new Marie-Curie Project

ALGALVANISE is an exciting new project, funded by the European Union's Marie-Curie programme, involving Celignis's Lalitha. It will advance the state of-

the art by developing two novel concepts:

1) enzyme-assisted enhanced algal cultivation; and

2) combinatorial bioflocculation using bacteria and biopolymers.

These two processes are targeted towards efficient nutrient recovery by algae from the digestate produced by anaerobic digestors and harvesting high-quality algal biomass to produce high-value functional ingredients.

We will update you, over the coming months and years, regarding the progress of this exciting project.

1) enzyme-assisted enhanced algal cultivation; and

2) combinatorial bioflocculation using bacteria and biopolymers.

These two processes are targeted towards efficient nutrient recovery by algae from the digestate produced by anaerobic digestors and harvesting high-quality algal biomass to produce high-value functional ingredients.

We will update you, over the coming months and years, regarding the progress of this exciting project.