Consolidated Bioprocessing (CBP) of Lignocellulosic Biomass

Lignocellulose Hydrolysis

Lignocellulosic biomass, primarily comprised of cellulose, hemicellulose, and lignin, is an abundant and renewable resource that holds great promise as a source of biofuels and renewable biobased chemicals and biomaterials. Lignocellulosic biomass can be processed in a number of ways, one is through the hydrolysis of the structural polysaccharides (cellulose and hemicellulose) into their constituent sugars, a reaction commonly facilitated by acid or enzymes, followed by the fermentation of these sugars by yeast or other microorganisms.Click below to read more about the hydrolysis of lignocellulosic biomass.

Get more info...Biomass Hydrolysis

Enzymatic Hydrolysis

In enzymatic hydrolysis cellulases and hemicellulases play a critical role, working synergistically to cleave the glycosidic linkages in cellulose and hemicellulose, respectively. However, depending on the type of pretreatment process involved, hydrolysis of hemicellulose may not be necessary, since it may have already taken place in the pretreatment leading to the hemicellulose sugars being in the liquid output of the pretreatment with the solid residue mostly containing cellulose (plus lignin, again dependent on the type of pretreatment).The enzymatic hydrolysis step can be carried out under relatively mild conditions, which makes it a more energy-efficient and environmentally friendly approach compared to chemical hydrolysis methods.

CBP Process

Consolidated bioprocessing (CBP), also known as direct microbial conversion, is a conceptual approach for integrated, one-reactor, biological conversion of lignocellulosic biomass to biofuels and biobased chemicals. By integrating enzyme production, saccharification (hydrolysis), and fermentation into a single step, CBP aims to simplify the process and reduce costs associated with biomass conversion.Each stage (enzyme production, enzymatic hydrolysis of polysaccharides, fermentation of sugars) of the traditional sequential biological conversion process usually involve different microorganisms and enzymes, and occur under different conditions, requiring separate reactors and significant process controls.

CBP aims to consolidate these steps into one. In the ideal case, a single microorganism or consortium of microorganisms is engineered to produce the necessary enzymes to break down lignocellulose, hydrolyse the biomass into sugars, and then ferment those sugars to ethanol or other desired products.

The concept of CBP is not limited to biofuel production. It also opens the door to the production of various bioproducts such as organic acids, amino acids, bioplastics, and many others, which can be obtained from fermenting the sugars released from lignocellulosic biomass.

The development of CBP organisms is at the forefront of research in this area. These include naturally-occurring cellulolytic microorganisms, genetically modified strains, and synthetic microbial consortia. To date, a fully-capable CBP strain or consortium that can efficiently degrade lignocellulosic biomass and ferment all the resulting sugars is still under development, and represents one of the main challenges in realizing the full potential of CBP. Despite these challenges, CBP holds promise for a more streamlined, economical, and efficient process for bioconversion of lignocellulosic biomass.

Advantages of CBP

- Simplified Process - Consolidating multiple stages into one reduces the process complexity. This simplification extends beyond the reduction in the number of operational steps and separate reactors. The consolidation leads to less equipment, lower energy costs, and a decrease in water and chemical inputs associated with each process stage. This helps to make the process more economically-viable and sustainable.

- Reduced Enzyme Costs - Enzymes required for hydrolysis in traditional biofuel production methods represent a considerable portion of the overall process cost. In CBP, the same microorganisms handle the production of hydrolytic enzymes, eliminating the need for externally-produced enzymes. The cost of enzyme production is therefore integrated into the fermentation step, eliminating the need for separate enzyme production and purification processes, further reducing operational costs.

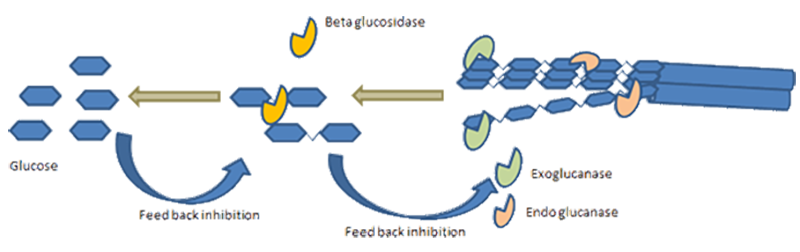

- Minimized Inhibitor Effects - In traditional methods sugars can accumulate during the hydrolysis process, inhibiting further enzymatic activity. However, in CBP, as the sugars are produced they are immediately consumed by the microorganisms for fermentation, preventing the buildup of these inhibitory products.

- Reduced Risk of Contamination - As all the steps are consolidated into one, there is a reduced risk of microbial contamination between stages. This could result in lower costs associated with sterilisation and lower losses of product due to contamination.

- Improved Carbon Utilisation - Since the ideal CBP organism or consortium can utilize both C5 and C6 sugars, there is potential for improved carbon utilisation compared to processes that can only use one type of sugar (usually glucose). This advantage could potentially increase the yield of biofuels or other bio-products per unit of lignocellulosic biomass.

- Potential for Lower Carbon Emissions - Given its simplified process and efficient use of resources, CBP could potentially lead to lower carbon emissions compared to traditional biobased chemicals production processes.

Disadvantages of CBP

- Engineering Challenges - Perhaps the most considerable hurdle facing CBP is the difficulty in developing a single microorganism or consortium of microorganisms capable of efficiently performing all necessary functions (enzyme production, hydrolysis, and fermentation). While there are organisms naturally capable of performing two out of three functions, no organism currently exists that excels in all three. Therefore, substantial genetic engineering is required to develop an ideal CBP strain. The manipulation and optimization of multiple metabolic pathways to meet the demands of CBP is a complex task that requires considerable research and development.

- Incompatibility of Conditions - Optimal conditions for hydrolysis and fermentation tend to be quite different. Hydrolysis generally requires higher temperatures and more acidic conditions to maximize enzymatic activity, while fermentation thrives at milder temperatures and near-neutral pH. Finding a compromise between these conditions that allow for efficient hydrolysis and fermentation simultaneously is a significant challenge, which might result in suboptimal rates of either or both processes.

- Slow Reaction Rates - In CBP, the enzymatic hydrolysis of cellulose and hemicellulose depends on enzymes produced by the fermentation organism(s) during the process. This dependence can result in a slower rate of enzymatic hydrolysis compared to processes where large amounts of purified enzymes are added at the beginning. The resultant slower rate of sugar release could limit the rate of fermentation, impacting process productivity.

- Cellulase Enzyme Expression - Successful CBP implementation requires the production of sufficient amounts of cellulase enzymes within the same microbial system that ferments the sugars. However, many traditional fermentation organisms, such as Saccharomyces cerevisiae, do not naturally produce these enzymes, necessitating extensive genetic engineering. Additionally, even when successful transformation is achieved, maintaining high levels of cellulase expression can be metabolically expensive for the microorganisms, potentially reducing the efficiency of the fermentation process.

- Lignin Degradation - Lignin is highly resistant to degradation and can hinder access to cellulose and hemicellulose. While some natural lignin-degrading organisms exist, incorporating this capability into a CBP organism or consortium adds another layer of complexity to the already significant engineering challenges. As a result, pretreatment, to remove lignin or to reduce its inhibitory effects on enzymatic hydrolysis is likely to still be needed in CBP.

- Limited Process Control - In CBP, all biological steps occur simultaneously in one reactor, reducing the ability to control each step individually. This could make it more challenging to optimize the process and troubleshoot any issues that arise.

Separate Hydrolysis & Fermentation (SHF)

Separate Hydrolysis and Fermentation (SHF) involves separate stages of enzymatic hydrolysis and fermentation, occuring in separate reactors.Advantages of CBP over SHF:

- Process Simplification - CBP consolidates the processes of enzyme production, hydrolysis, and fermentation into a single step, reducing the overall complexity of the biofuel production process. On the other hand, SHF requires separate stages for hydrolysis and fermentation, demanding more operational and management effort.

- Reduced Costs - As CBP generates required enzymes in situ, it eliminates the need for expensive externally-produced enzymes, thereby reducing production costs. SHF, on the other hand, requires the addition of costly enzymes for the hydrolysis stage.

- Minimized Inhibitor Effects - CBP reduces the buildup of sugars, which can inhibit enzyme activity, by allowing the microbes to consume the sugars as they are produced. In SHF, sugars accumulate during the hydrolysis phase, which can lead to product inhibition, reducing the efficiency of the process.

- Less Risk of Contamination - With all steps consolidated in one reactor, CBP reduces the chances of contamination between stages. SHF, which involves separate stages, has a higher risk of microbial contamination.

- Engineering Challenges - The most significant challenge for CBP is the development of a single organism or microbial consortium capable of effectively performing all necessary tasks (enzyme production, saccharification, and fermentation). In SHF, different specialized organisms or conditions can be optimized for each step, which can be easier than finding or creating a single organism that can perform all steps efficiently.

- Incompatibility of Conditions - Optimal conditions for hydrolysis and fermentation are different, and finding a balance between these conditions in a single CBP reactor is challenging. SHF, however, can independently optimise conditions for each process.

- Slow Reaction Rates - CBP can have slower reaction rates due to the dependence on the fermentation organisms for enzyme production. SHF, in contrast, allows for the addition of large amounts of purified enzymes at the start of the hydrolysis step, which can result in a faster rate of sugar release.

- Limited Process Control - CBP has limited ability to control individual process steps as they occur simultaneously. However, SHF allows more precise control and optimization of each process step as they occur separately.

Get more info...SHF

Simultaneous Saccharification and Fermentation (SSF)

Simultaneous Saccharification and Fermentation (SSF) is a process where enzymatic hydrolysis and fermentation occur concurrently in the same reactor, however the enzymes are produced externally (unlike in CBP).Advantages of CBP over SSF:

- Cost-Effectiveness - In CBP, the microbes used produce their enzymes for hydrolysis, eliminating the need for externally-produced enzymes. SSF still requires the addition of these enzymes, leading to higher overall costs.

- Simplified Workflow - CBP consolidates all biological steps in a single reactor, making the process more straightforward versus SSF which requires separate enzyme production.

- Reduced Contamination Risk - The single-reactor process of CBP reduces the chances of microbial contamination between stages, which can occur in SSF during the addition of enzymes or the switch from hydrolysis to fermentation.

- Microbial Development Challenges - CBP requires a microbe or microbial consortium that can efficiently perform all necessary biological functions. This kind of comprehensive functionality is hard to find or develop, unlike in SSF, where different organisms or enzymes can be used for each step.

- Suboptimal Conditions - Finding a balance between optimal conditions for hydrolysis and fermentation in one reactor, as required in CBP, can be challenging. On the other hand, in SSF, once the enzymes are added and hydrolysis begins, the conditions can adjust for optimal fermentation.

- Slow Hydrolysis Rates - The rate of enzymatic hydrolysis in CBP depends on the production of enzymes by the fermentation microorganisms, which can be slower than in SSF, where large amounts of enzymes can be added at the start.

- Limited Process Control - Since all steps occur simultaneously in one reactor in CBP, it is harder to control and optimize each process step independently, unlike in SSF, where hydrolysis and fermentation can be controlled more independently, albeit in the same reactor.

Get more info...SSF

Lalitha Gottumukkala

Founder of Celignis Bioprocess, CIO of Celignis

PhD

Has a deep understanding of all biological and chemical aspects of bioproceses. Has developed Celignis into a renowned provider of bioprocess development services to a global network of clients.

Oscar Bedzo

Bioprocess Project Manager & Technoeconomic Analysis Lead

PhD

A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.