Production of 1,3-Propanediol Through Fermentation

Background to 1,3-Propanediol Fermentation

Natural microbes that produce 1,3-Propanediol are Klebsiella, Clostridia, Citrobacter, Enterobacter and Lactobacilli. They all use glycerol as a carbon source and produce 1,3 PDO through 3-hydroxypropionaldehyde route

using glycerol dehydratase enzymes and 1,3-propanediol oxidoreductase enzymes. The biggest constraint for microbial production of 1,3 PDO is low yield and productivity which is due to multiple reasons including:

as low cell density, irreversible inhibition of glycerol dehydratase enzyme with glycerol, and requirement of speciality ingredients such as vitamins.

Though the use of waste glycerol from biofuel industry is highly advocated, its usage will cause more complications due to microbial inhibition with the presence of methanol, surfactants, and free fatty acids.

Though the use of waste glycerol from biofuel industry is highly advocated, its usage will cause more complications due to microbial inhibition with the presence of methanol, surfactants, and free fatty acids.

Hence, raw glycerol from industrial streams should be pretreated to remove inhibitors before using it for 1,3-Propanediol or should adapt or isolate the strain to tolerate the inhibitors.

Fermentation strategies should avoid cell toxicity of glycerol and autolysis processes. This can be achieved by following techniques like fed-batch fermentation, sequential fermentation, and immobilised cells. The most suitable downstream technique should be employed for purification of 1,3-PDO in order to make the process economically viable.

Fermentation strategies should avoid cell toxicity of glycerol and autolysis processes. This can be achieved by following techniques like fed-batch fermentation, sequential fermentation, and immobilised cells. The most suitable downstream technique should be employed for purification of 1,3-PDO in order to make the process economically viable.

How Celignis Can Help

At Celignis, we have expertise and experience in performing anaerobic fermentations

and developing fermentation strategies to achieve high cell mass and in situ product recovery techniques. We can screen your feedstock for 1,3-Propanediol production,

adapt the strain to any inhibitors present in the feed, and develop bespoke fermentation and product recovery process.

Our team of experts will innovate with you for you.

Get more info...Get in Touch

Our team of experts will innovate with you for you.

Get more info...Get in Touch

Lactic Acid Fermentation

Lactic acid bacteria are very sensitive and require complex nutrient media compared to other bacillus species that can produce lactic acid.

Hence, industries are constantly looking for fungi and bacillus strains that have low nutrient requirements and can tolerate acidic pH.

At Celignis we have expertise and experience in screening lactic acid bacteria for the selection of substrate- and product-tolerant strains. We can also develop: fed-batch strategies to achieve high cell mass, and in situ product recovery techniques to separate lactic acid from the fermentation broth. We will work with you and develop bespoke lactic acid fermentation methods for your feedstock or industrial waste streams.

Get more info...Lactic Acid Fermentation

At Celignis we have expertise and experience in screening lactic acid bacteria for the selection of substrate- and product-tolerant strains. We can also develop: fed-batch strategies to achieve high cell mass, and in situ product recovery techniques to separate lactic acid from the fermentation broth. We will work with you and develop bespoke lactic acid fermentation methods for your feedstock or industrial waste streams.

Get more info...Lactic Acid Fermentation

Propionic Acid Fermentation

Propionic acid can be produced from a variety of substrates such as glucose, ethanol, lactose, glycerol, and pectin. So, several industrial streams

will be suitable to produce propionic acid, if the bacteria are adapted to the inhibitors present in the waste streams and fermentation is optimised to

achieve high cell densities and high product concentration.

We can perform anaerobic fermentations and develop fermentation strategies to achieve high cell mass and in-situ product recovery techniques. We can screen your feedstock for propionic acid production, adapt the strain to any inhibitors present in the feed, and develop bespoke fermentation and product recovery processes.

Get more info...Propionic Acid Fermentation We can perform anaerobic fermentations and develop fermentation strategies to achieve high cell mass and in-situ product recovery techniques. We can screen your feedstock for propionic acid production, adapt the strain to any inhibitors present in the feed, and develop bespoke fermentation and product recovery processes.

Butyric Acid Fermentation

Butyric acid is biologically produced by Clostridium species and like other acids (acetic acid, lactic acid, propionic acid),

it is toxic to the bacteria after a certain concentration. Hence, the product titres are generally low which makes downstream expensive.

In order to reduce these costs, in situ removal of butyric acid can be developed. In situ removal strategies are not yet industrially applied for butyric acid, but

it is a key area where progress has to be made to make the process economically sustainable.

At Celignis, we have strong expertise in Clostridial fermentation. We can isolate and or adapt the strains that are suitable for your feedstock and can develop fermentation strategies to reduce substrate and product inhibition. We will innovate with you for you.

Get more info...Butyric Acid Fermentation

At Celignis, we have strong expertise in Clostridial fermentation. We can isolate and or adapt the strains that are suitable for your feedstock and can develop fermentation strategies to reduce substrate and product inhibition. We will innovate with you for you.

Get more info...Butyric Acid Fermentation

Butanol Fermentation

Butanol fermentation is also one of the difficult fermentation pathways due to substrate and product inhibition. However, this can be

avoided by fed-batch fermentation and in-situ stripping of butanol. Also, reducing the feedstock and enzyme costs will make the process more

economically viable. Through using industrial waste streams (negative costs), enzymatic cocktails tailored for the feedstock (allowing low-enzyme dosages), and

with high sugar yields, the right choice of microbial strain, and an effective in-situ removal technology, it is possible to develop an economically-viable butanol process.

At Celignis, we have considerable expertise in Clostridial fermentation and especially butanol fermentation. Our Chief Innovation Officer Dr Lalitha Gottumukkala has extensively worked in this area and has isolated novel strains and developed novel methods for non-acetogenic butanol fermentation as part of her PhD.

Get more info...Butanol Fermentation

At Celignis, we have considerable expertise in Clostridial fermentation and especially butanol fermentation. Our Chief Innovation Officer Dr Lalitha Gottumukkala has extensively worked in this area and has isolated novel strains and developed novel methods for non-acetogenic butanol fermentation as part of her PhD.

Get more info...Butanol Fermentation

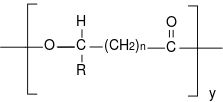

Polyhydroxy Alkanoates (PHAs) Production

PHA is one of the most complicated fermentation processes, but the possibility to use mixed microbial cultures and the avoidance of sterilisation costs

makes it an interesting process to produce bioplastics. Also, PHA blends are becoming more and more popular to increase the tensile strength and

flexibility of the polymer, possible by using mixed culture substrates.

At Celignis, we have experience in enrichment of desired microorganisms, fed-batch and continuous fermentations with cell-recycling. We can design and develop the most suitable process for your feedstock by using mixed or mono-culture fermentations. We can also develop cost-efficient downstream processing steps for efficient PHA extraction by using non-toxic and environmentally friendly techniques.

Get more info...PHA Production Fermentation

At Celignis, we have experience in enrichment of desired microorganisms, fed-batch and continuous fermentations with cell-recycling. We can design and develop the most suitable process for your feedstock by using mixed or mono-culture fermentations. We can also develop cost-efficient downstream processing steps for efficient PHA extraction by using non-toxic and environmentally friendly techniques.

Get more info...PHA Production Fermentation

Yeast and Fungal Fermentation

Yeast fermentation is one of the oldest fermentations and is used in everyday life to produce a variety of commodity products including bread, beer, wine,

cheese, and soy sauce. A few decades ago, yeast gained popularity as an industrial strain for biorefinery and biofuel applications.

At Celignis, we can use yeast and fungi for the production of: bioethanol, glycerol, single cell oils (SCOs), and emulsifiers, among other products.

Get more info...Yeast and Fungal Fermentation At Celignis, we can use yeast and fungi for the production of: bioethanol, glycerol, single cell oils (SCOs), and emulsifiers, among other products.

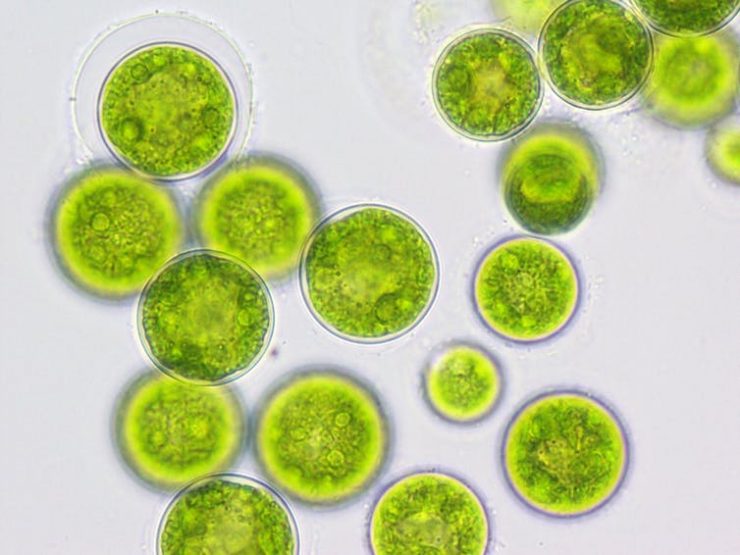

Microalgal Fermentation

Algal cultivation is complicated and requires optimisation to achieve high biomass yields. Algal biomass production depends on nutrient uptake and

other environmental conditions such as temperature, pH, salt concentration etc. It is important to select the strain based on the type of

production (open ponds, photobioreactors), feedstock and application. We have particular expertise in the evaluation and optimisation of algae thorugh

our Chief Innovation Officer, Lalitha, who is currently undertaking a Marie-Curie funded project at Celignis on this topic.

Get more info...Microalgae Fermentation Contact Us For Further Details

We are available to answer any questions you may have on how to get high value chemicals and biofuels from biomass through fermentation processes.

Just get in touch with us by sending us an email info@celignis.com, giving us a call at (+353) 61 371 725, or through

our contact form.

Get more info...Get in Touch

Get more info...Get in Touch