Biomass Research at Celignis USA

To help tackle these issues there have been a number of funding programmes, in the USA and overseas, for research projects to advance the art and economics of biomass technologies. Examples in the USA include:

- The Bioenergy Technologies Office (BETO) from the Department of Energy.

- US Departmernt of Agriculture (USDA) programmes such as AFRI.

- Small Business Innovation Research (SBIR) and Small Business Technology Transfer (STTR) programmes.

Celignis USA is eager to collaborate in the advancement of the US bioeconomy. We are SAM.gov registered and eligible for full participation in funded projects looking to advance the state-of-the-art in biomass valorization. We can provide contributions in several domains (e.g. cellulosic fuels, seaweed utilisation, biochar, RNG sector) as either a parner focused on analytical or bioprocess development aspects. We can also be involved in the preparation of scientific articles for such projects (click here to see a selection of the over 50 publications by members of the Celignis family) as well as in the development of proposals for funding.

History of Research at Celignis

Celignis was Born from Pioneering Research

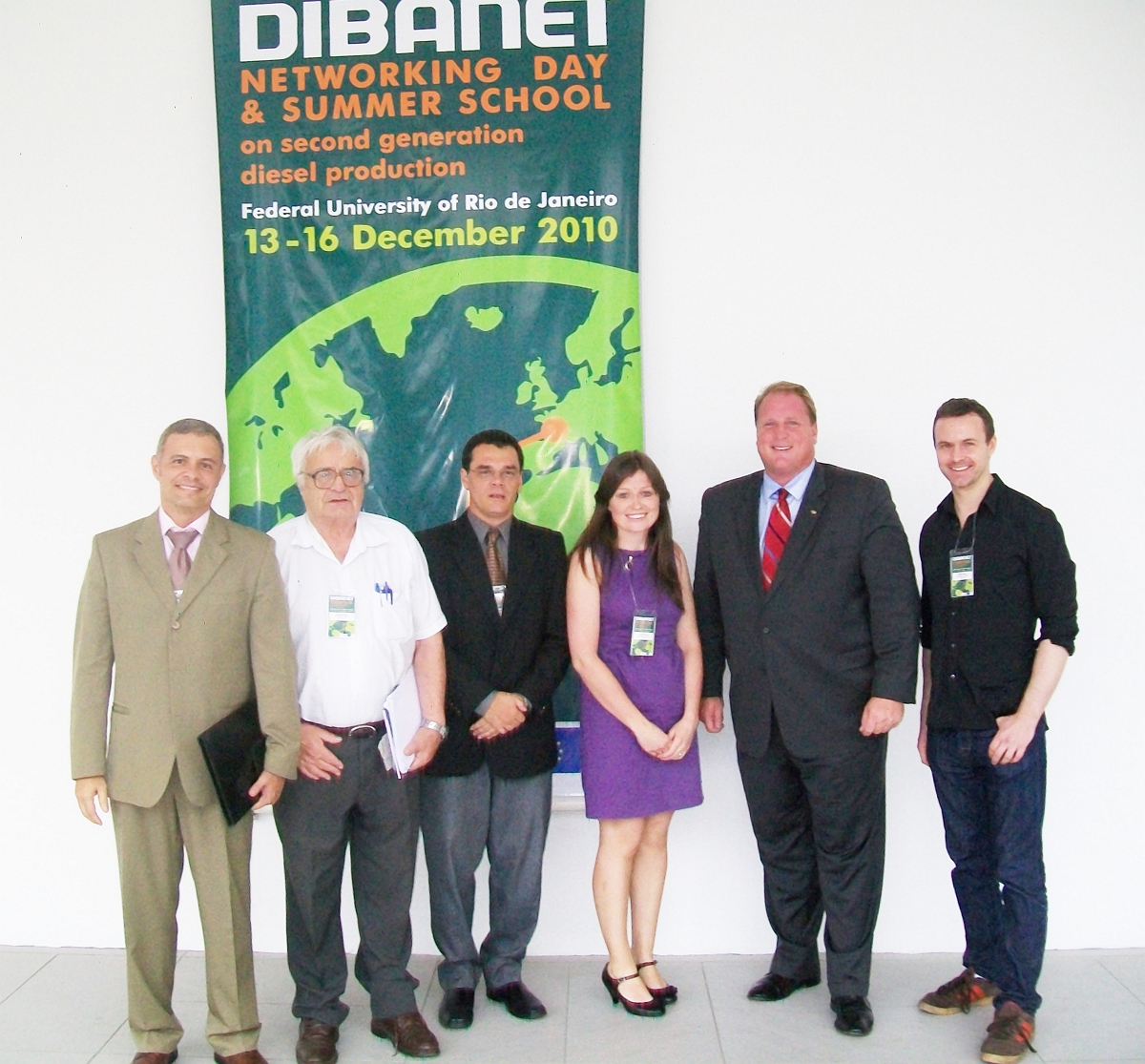

One output of DIBANET was the development of rapid biomass analysis models which led to Dan spinning-out Celignis in 2014.

Prior to that he also wrote and managed a number of other research projects during his placement at the University of Limerick.

In 2018 Dan made a presentation entitled "Spinning Our from an EU Research Project: The Story so Far" at the ECO-BIO conference in Dublin, Ireland. It covered the background to the formation of Celignis and observations regarding the process of commercialising research. Click here to download that presentation.

Celignis's Growing Recognition as a Research Partner

In 2021 Celignis (Ireland) was winner of the Innovation of the Year award at the Irish Laboratory Awards.

Current Projects at Celignis

Click here to read a recent pitch from Celignis concerning the company's areas of expertise for involvement in future research project proposals.

The biofuel production potentials for encroacher and invasive bush biomass species found in Southern Africa were assessed using different valorization routes. Theoretical models were employed to calculate the biofuel yields. The gasification-catalytic route produced highest ethanol yields (450–488 L/t) while the lowest values were from enzymatic/acid hydrolysis-to-fermentation route. Blue gum gave the highest ethanol yields. Biodiesel and naphtha yields produced through Fischer-Tropsch synthesis were highest for blue gum (196 L/t) and lowest for Acacia raficiens (176 L/t). The highest biogas and biomethane potential of 458 L/kg.VS and 229 L/kg.VS respectively were obtained from black wattle while the respective lower values (270 L/kg.VS and 132 L/kg.VS) were recorded for blue gum. Senegalia mellifera gave the highest torrefied biofuel energy and mass yields at 0.92 and 0.97 respectively while black wattle had the lowest mass and energy yields at 0.75 and 0.83 respectively. From an energy yield basis, the acid hydrolysis-fermentation route yielded an average of 3.69 GJ/t of biomass while the highest yields came from the gasification-catalytic conversion route which was 9.7 GJ/t. The average energy yield variations across biomass species ranged 5.11–6.19 GJ/t which is around 30 % of the raw biomass' calorific value. These early results provide insights towards the best pairing of appropriate biomass species and energy conversion route. Further evaluations of these biomass-valorization technology pairing to unpack process efficiencies, cost and kinetics are required using real process experiments instead of using theoretical models. These additional tests should include sustainability assessment to guide future commercialization decisions. | |

Fruit juice processing generates large volumes of organic waste, including pomace, retentate, and waste apples, that are a challenge to manage. Anaerobic digestion (AD) allows for conversion of these wastes into biogas; however, their high acidity and low buffering capacity limits AD process stability, leading to reduced methane yield. In this study, co-digestion with manure and lignocellulosic biomass (LCB) was assessed. A five-factor mixture design was used to test different combinations on a bench scale, selected based-on seasonal fruit waste availability. Process performance was assessed based-on methane yield and volatile fatty acids before and after AD. Feedstock mixture representing an off-season blend of 20% pomace, 30% retentate and 50% manure, as well as an in-season blends of 20% waste apples, 30% pomace, 30% retentate, and 20% manure, were found to maximise the biomethane yield. Supplementation with at least 20% manure was essential for fruit waste digestion. Replacing a portion of the fruit waste with lignocellulose in the anaerobic digestion significantly improved the methane yield and prevented an “acid crash”. It was found that 30% LCB and 20% manure supplementation were the minimum required for anaerobic digestion process stability and yield for both in- and off-season fruit harvesting and processing. | ||

Seaweed, an abundant third-generation biomass, has garnered significant interest for hydrocolloid extraction due to its unique composition. The extraction of these hydrocolloids, coupled with the negligible presence of lignin, leaves behind a cellulose-rich residue ideal for nanocellulose production—a potential that remains underexplored. Nanocellulose, known for its versatility, finds applications across composite, fibre, and medical industries. This review delves into the structure, composition, and extraction processes of seaweed hydrocolloids. It also investigates green emerging pretreatment techniques for hydrocolloid extraction, evaluating their advantages and limitations. This review further analyses nanocellulose produced from seaweed residues, focusing on treatment types, morphology, thermal stability, and crystallinity to determine optimal applications. Lastly, a comprehensive biorefinery approach is proposed, integrating hydrocolloid extraction and nanocellulose production to maximize the benefits from the seaweed industry. | |

This study presents a method for effective pectin extraction from the laminae of three tobacco varieties as a means of biomass valorisation. Two pre-treatment methods (cold ethanol vs. accelerated solvent extraction [ASE] with ethanol) were compared for their capacities to produce a high pectin yield. Enzymatic extraction of pectin was also tested as a green extraction procedure and compared to the acid extraction approach. The optimisation experiments revealed that cold ethanol extraction followed by acid hydrolysis is the most convenient method for pectin extraction; the optimal set of conditions for hydrolysis were identified as 90°C, pH 1.5, and 4 h of extraction. Applying these optimised conditions to the three Nicotiana rustica tobacco varieties yielded pectin recoveries of 66.2%, 57.8%, and 56.7% from the NRT63, Bakoum Miena, and NRT61 samples, respectively. Tobacco pectins were found to have a medium molecular weight and low methoxy content. These results highlight the potential of tobacco residues as feedstock for to produce pectin with dietary applications. | |||

The production of high-value commodities from sugarcane bagasse and harvest residues could be integrated into existing sugarcane mills to create sugarcane biorefineries. Three distinctly different domains of operating conditions were optimised for autocatalyzed steam pretreatment and enzymatic hydrolysis of these lignocelluloses, to provide sugars according to biorefinery priorities, i.e. (i) maximum digestibility of the solids for glucose only, (ii) maximum hemicellulose recovery in the prehydrolysate for xylose only, or (iii) maximum combined sugar yield (CSY; glucose plus xylose). Bagasse pretreatment showed isolated optima for each response at (i) 215 °C, 15 min; (ii) 202.2 °C, 5 min; and (iii) 215 °C, 5 min. For the harvest residues, the three domains of optimum conditions overlapped within temperatures of 198 and 200 °C, and times of 8 and 12°min, allowing for a single pretreatment condition that meets all three criteria. The practicality and robustness of the preferred pretreatment conditions were demonstrated with a mixed stream of both feedstocks. | |

Brewers spent grains (BSGs) represent the largest quantity of solid waste from brewing, while xylooligosaccharides (XOS) produced from BSG show promising applications in food, beverage and health products. Production of XOS from a Weiss and malt BSG was scaled-up in steam explosion hydrothermal treatment using process conditions from bench-scale liquid hot water optimisations in stirred batch reactors. Three levels of moisture (15, 25 and 32% dry matter) achieved by screw press dewatering were evaluated by varying the treatment temperatures and times. Results show the highest XOS yields (73.1%) were obtained, for both BSGs, at process condition selected (180 C, 10 min) with 25% initial dry matter content. These yields were higher than reported bench-scale optimisations (61%), but obtained using 60% less water; hence, initial dry matter content was an important variable affecting XOS yield. The pilot-scale steam explosion results provide a departing point for a cost-effective commercial production of XOS from BSG. | |

Anaerobic digestion (AD) is a bioprocess technology that integrates into circular economy systems, which produce renewable energy and biofertilizer whilst reducing greenhouse gas emissions. However, improvements in biogas production efficiency are needed in dealing with lignocellulosic biomass. The state-of-the-art of AD technology is discussed, with emphasis on feedstock digestibility and operational difficulty. Solutions to these challenges including for pre-treatment and bioaugmentation are reviewed. This article proposes an innovative integrated system combining alkali pre-treatment, temperature-phased AD and bioaugmentation techniques. The integrated system as modelled has a targeted potential to achieve a biodegradability index of 90% while increasing methane production by 47% compared to conventional AD. The methane productivity may also be improved by a target reduction in retention time from 30 to 20 days. This, if realized has the potential to lower energy production cost and the levelized cost of abatement to facilitate an increased resource of sustainable commercially viable biomethane. | ||

weet sorghum bagasse displays many characteristics rendering it a promising substrate for lignocellulosic ethanol production. In this study, the steam pretreatment catalyst, enzymatic hydrolysis and the substrate loading for the fermentation were investigated in order to maximise the production of ethanol from the feedstock. The results deemed water as a sufficient pretreatment catalyst since the SO2 impregnation of the biomass did not produce any significant beneficial effects on the yield of ethanol produced. The preferred pretreatment and enzymatic hydrolysis conditions were incorporated in a fed-batch simultaneous saccharification and fermentation (SSF) process using pressed-only (not washed) WIS at a final solid loading of 13% (w/w) that resulted in the targeted ethanol concentration of 39 g/L with a corresponding yield of 82% of the theoretical maximum. Yeast inhibition coupled with significant glucose accumulation was observed at higher solid loadings of 16% and 20%. Ultimately, the sweet sorghum bagasse could be integrated into existing ethanol production regimes to improve the global bioenergy production. | |

Brewers' spent grains (BSG) make up to 85% of a brewery's solid waste, and is either sent to landfill or sold as cheap animal feed supplement. Xylo-oligosaccharides (XOS) obtained from BSG are antioxidants and prebiotics that can be used in food formulations as low-calorie sweeteners and texturisers. The effect of extremely low acid (ELA) catalysis in liquid hot water (LHW) hydrothermal treatment (HTT) was assessed using BSG with dry matter contents of 15% and 25%, achieved by dewatering using a screw press. Batch experiments at low acid loadings of 5, 12.5 and 20 mg/g dry mass and temperatures of 120, 150 and 170 C significantly affected XOS yield at both levels of dry mass considered. Maximum XOS yields of 76.4% (16.6 g/l) and 65.5% (31.7 g/l) were achieved from raw BSG and screw pressed BSG respectively, both at 170 C and using 5 mg acid/g dry mass, after 15 min and 5 min, respectively. These XOS yields were obtained with BSG containing up to 63% less water and temperatures more than 20 C lower than that reported previously. The finding confirms that ELA dosing in LHW HTT allows lowering of the required temperature that can result in a reduction of degradation products, which is especially relevant under high solid conditions. This substantial XOS production intensification through higher solid loadings in HTT not only achieved high product yield, but also provided benefits such as increased product concentrations and decreased process heat requirements. | |

Knowing the accurate composition of biomass is of crucial importance in order to assess and decide on the use and processes to be applied to specific biomass types. In this study, the composition of the lignocellulosic constituents present in forestry, agricultural and underutilised waste residues was assessed. Considering the increased interest on hemicellulose fractions for application in biomaterials and biomolecules, large emphasis has been given in detailing the monomeric constituents of the hemicellulose polymer. Lignin and cellulose, the two other major components of lignocellulosic biomass, were analysed and correlated with the trends in the other constituents. In the samples analysed, the total structural sugars content ranged from 26.0 to 67.5% of the biomass dry weight, indicating high variation between different feedstock and fractions. Hemicellulose concentration and composition also varied significantly (from 38.8% in birch (Betula Pendula Roth) foliage to 22.0 % in rice (Oryza sativa L.) straw) between the feedstock types and within the same feedstock type between different species and different fractions. The extractives content varied greatly between the different species (from 2.66 % to 30.47 % of the biomass dry weight) with high contents in certain fractions of feedstock suggesting more detailed compositional analysis of these extracts is warranted. | ||

Six conceptual process scenarios for the production of biobutanol from lignocellulosic biomass through acetone?butanol?ethanol (ABE) fermentation, using reported data on process performances, were developed with ASPEN Plus® V8.2 software. The six scenarios covered three fermentation strategies, i.e. batch separate hydrolysis and fermentation (SHF), continuous SHF, and batch simultaneous saccharification and fermentation (SSF) integrated with gas stripping (GS). The two downstream processing options considered were double?effect distillation (DD) and liquid?liquid extraction and distillation (LLE&D). It was found that the SSF?GS/DD scenario was the most energy efficient with a liquid fuel efficiency of 24% and an overall efficiency of 31%. This was also the scenario with the best economic outcome, with an internal rate of return (IRR) of 15% and net present value (NPV) of US$387 million. The SSF?GS/DD scenario was compared to a similar molasses process, based on the product flow rates, and it was found that the molasses process was more energy efficient with a gross energy value (GEV) of 23?MJ?kg1 butanol compared to ?117?MJ?kg1 butanol for the lignocellulosic process. In addition, the molasses?based process was more profitable with an IRR of 36% compared to 21%. However, the energy requirements for the molasses process were supplied from fossil fuels, whereas for the lignocellulose processes a portion of the feedstock was diverted to provide process energy. Improved environmental performance is therefore associated with the lignocellulosic process. | |

Preheating with hot air at 85-125 C was evaluated for its effectiveness in removing terpenes and terpenoids in softwood sawdust, thereby enhancing fungal preprocessing and subsequent saccharification of softwood-based mushroom substrates. Sawdust from pine (Pinus sylvestris L.) and spruce (Picea abies (L.) H. Karst.) was preheated prior to shiitake (Lentinula edodes (Berk.) Pegler) cultivation. Preheating removed up to 96?% of terpenes in pine- based substrates and up to 50?% in spruce-based substrates. Additionally, preheating decreased total terpenoids content in spruce by up to 78?%. For the pine-based substrate, the mild heating generally led to faster colonisation and improved mushroom yield, with the fastest mycelia colonisation and highest yield observed for 105 C treatment. This temperature was associated with the lowest content of total terpenes and absence of major monoterpenes. The content of terpenes and terpenoids continued to decrease during cultivation, alongside fungal degradation of lignocellulose. As a result of more extensive lignin degradation, the enzymatic digestibility of cellulose was higher for spruce-based spent mushroom substrate than for pine-based one (up to 89?% vs. 49?% conversion). Enzymatic digestibility showed a negative correlation with the a-pinene content, and a positive correlation with increasing preheating temperatures. | |

As a result of the current high throughput of the fast fashion collections and the concomitant decrease in product lifetime, we are facing enormous amounts of textile waste. Since textiles are often a blend of multiple fibers (predominantly cotton and polyester) and contain various different components, proper waste management and recycling are challenging. Here, we describe a high-yield process for the sequential chemical recycling of cotton and polyester from mixed waste textiles. The utilization of 43 wt% hydrochloric acid for the acid hydrolysis of polycotton (44/56 cotton/polyester, room temperature, 24 h) results in a 75% molar glucose yield from the cotton fraction, whereafter the hydrolysate solution is easily separated from the solid polyester residue. The reaction is scalable, as similar results are obtained for experiments performed at 1?mL, 0.1, and 1.0?L and even in a 230?L pilot plant reactor, where mixed postconsumer polycotton waste textile is successfully recycled. The residual polyester is successfully converted via glycolysis to bis(2-hydroxyethyl) terephthalate in 78% isolated yield (>98% purity). | |

The utilisation of lignocellulosic biomass for energy production has gained significant attention in recent years as a strategy to reduce carbon emissions and achieve renewable energy and net-zero targets. However, the recalcitrance of lignin in biomass hinders the effectiveness of biomethane production from anaerobic digestion, necessitating pretreatment. This study investigates the impact of a novel microbubble plasma-assisted pretreatment on structural changes in lignocellulosic biomass (maize, wheat, and rice husk) with subsequent biomethane generation. Pretreatment conditions, including durations of 1 h and 3 h under neutral, acidic (pH 3), and alkaline (pH 9) environments, were systematically investigated. Comprehensive material characterisation of untreated and pretreated material using ATR-FTIR, TGA, SEM, and XRD indicated physicochemical changes in the biomass structure, where ATR-FTIR detected lignin disruption, SEM revealed surface morphology changes, and XRD revealed minor crystallinity changes. The potential of pretreated material to generate biogas was tested using the standard BMP test. Maize pretreated in tap water for 1 h resulted in the highest biomethane yield improvement of 18% among the tested conditions. Conversely, for longer pretreatment durations of 3 h, the formation of inhibitory compounds resulted in reduced yields. Wheat and rice husk pretreated in tap water for 1 h also increased yields, but only slightly, by 5% and 7%, respectively. This study emphasises the need to optimise pretreatment duration and conditions to balance lignin breakdown and inhibitor formation and illustrates the potential of microbubble plasma-assisted pretreatment for improving Anaerobic Digestion (AD) efficiency. | |

The reaction mechanism and kinetics of the sulfuric acid catalysed ethanolysis of glucose, cellulose, xylan, and corncob were investigated using a combination of experiments and empirical reaction mechanism modelling. The experimental study was carried out in ethanol at various temperatures between 150 C and 200 C. Ethanol mediates the depolymerisation and formation of ethyl levulinate from the carbohydrates in the substrates. Ethanol itself is converted to the corresponding ether in a parallel acid-catalysed condensation reaction. The complementary synergistic thermal and combustion properties of the main components in the resulting mixture, ethyl levulinate, diethyl ether, and ethanol, create the potential for the use of the product mixture as a tailored drop-in biofuel. The concentrations of the main species in the product mixtures from the reaction experiments were used to build a hierarchical surrogate kinetic model based on feedstock composition. The reaction mechanism provided to the surrogate kinetic model is informed by a comparative experimental mechanistic study of the ethanolysis of glucose and fructose. The study shows that the major reaction species formed from glucose ethanolysis are ethyl glucoside and ethyl levulinate, whereas fructose ethanolysis primarily forms 5-hydroxymethylfurfural, 5-ethoxymethylfurfural, ethyl fructoside and ethyl levulinate. The study shows that fructose produces a higher yield of ethyl levulinate than glucose and that fructose does so at a rate approximately ten times faster than glucose. The rate of formation of both ethyl levulinate and diethyl ether increases with increasing temperature. The maximum yields (mass%) of ethyl levulinate achieved from the ethanolysis of glucose, cellulose, xylan, and corncob are 39.3, 39.1, 7.9, and 18.6%, respectively. Ethyl levulinate yields reach a maximum steady state value for each feedstock that is independent of temperature. The conversion of the model compounds, glucose, cellulose, and xylan, to ethyl levulinate in the presence of ethanol and sulfuric acid is a catalytic process. However, for corncob, the yield of ethyl levulinate is dependent on the concentration of sulfuric acid in the reaction. This effect is also observed in the mass fraction of diethyl ether formed, indicating that the hydrogen cation supplied by sulfuric acid is not being fully replenished in the corncob ethanolysis process. A corncob[thin space (1/6-em)]:[thin space (1/6-em)]acid mass ratio of 10[thin space (1/6-em)]:[thin space (1/6-em)]1 is identified as a sufficient sulfuric acid concentration to achieve a maximum steady state yield of ethyl levulinate. An empirical analysis of the experimental data show that the apparent activation energies of the global reaction of glucose to ethyl levulinate and ethanol to diethyl ether are 21.5 and 23.0 kcal mol-1, respectively. The hierarchical surrogate kinetic model for the ethanolysis of corncob based on its composition of cellulose, hemicellulose, and lignin was developed and has an overall R2 value of 0.88. The model was exercised to predict the major trends of the reaction system at various hypothetical conditions, demonstrating its utility as tool for process development. | |

Understanding the transcriptional regulation of biomass accumulation and sucrose storage is critical for enhancing sugarcane productivity. In this study, we quantified transcription factor protein (TFP) abundance across sugarcane internodes at different developmental stages and growth rates, correlating these profiles with key biochemical traits including lignin, glucan, hemicellulose, and sucrose content. Among 7333 proteins identified, 205 were classified as transcription factors spanning 22 families. Trait-centric correlation networks revealed 107 TFP-trait associations via Pearson correlation; refinement using the Partial Correlation with Information Theory (PCIT) algorithm identified 46 high-confidence regulatory links. Key transcription factors, such as ScMYB113, ScMADS15, and ScbZIP85, displayed trait-specific roles in coordinating sucrose storage and cell wall biosynthesis. Network topology uncovered distinct regulatory modules associated with biomass production, structural polysaccharide deposition, and intermediary metabolism. Notably, sucrose and lignin accumulation primarily occurred after internode elongation ceased, implicating shifts in transcriptional regulation during maturation. This study delivers the first protein-level regulatory map linking TF abundance to metabolic traits in sugarcane and provides a robust framework for identifying candidate regulators to optimize biomass quality and yield for bioenergy applications. | |

We report a simple procedure to produce carboxylated cellulose nanocrystals (CNCs) from grassy biomass (Miscanthus X Giganteus) using a two-step approach consisting of biomass fractionation with a protic ionic liquid followed by oxidation of the resulting cellulose-rich pulps with H2O2. The impact of the fractionation severity on the composition, structure, size, thermal stability, crystallinity, and degree of polymerization of the CNCs was evaluated. It was found that fractionation severity had a large impact on the pulp purity and its reactivity during the oxidation stage. Nevertheless, the impact on the properties of the final CNCs was small. CNCs were recovered as suspensions of negatively charged, electrostatically stable, needle-like CNCs with a lower degree of crystallinity (58-61%) compared to the precursor pulps (65-69%). The presence of carboxyl groups on the surface of the CNCs facilitated the stability of the suspensions but also caused a slight decrease in the thermal stability of the CNCs. A milder oxidation process followed by ultrasonication allowed us to maximize the production of CNCs while better preserving the degree of crystallinity of the cellulose (63%). | |

Sugar kelp (Saccharina latissima), a brown macroalga, is a vital crop in the burgeoning seaweed aquaculture industry. As seaweed farms expand, the traditional practice of collecting wild sporophytes will be unsustainable. Developing new kelp cultivars that suit multiple farm conditions is necessary. To address this challenge, our breeding project selected six sugar kelp crosses to be grown in New Castle, New Hampshire; Duxbury, Massachusetts; and Moriches, New York, in the 2022-2023 growing season. We measured four plot level traits (wet weight, dry weight, sporophyte density, and percent dry weight), five single blade level traits (blade length, blade maximum width, blade thickness, stipe length, and stipe diameter), and three tissue composition traits (ash content, carbon content, and nitrogen content). All plot level traits except for the percent dry weight were affected by both crosses/genotypes (G) and farm site/environments (E). All blade level traits were significantly affected by crosses. Farm effects were only detected on blade maximum width and stipe diameter. For the tissue composition traits, ash content was not affected by either cross or farm site. Carbon content was only significantly affected by the farm site, while the nitrogen content was affected by farm site, cross and their interaction effects. These findings suggest that multi-farm testing for sugar kelp breeding programs is important for determining the best crosses for various growers. Understanding G by E effects can advance sugar kelp breeding for targeted traits and farms that will facilitate the adoption of cultivars toward sustainable economic growth on diverse kelp farms. | |

Economic production of fermentable sugars from lignocellulosic biomass is critical for the biorefinery applications in the bioeconomy industry. This study demonstrates effective enzymatic hydrolysis of recalcitrant softwood using newly identified fungus Penicillium rotoruae. Initially, nineteen fungal isolates were screened on softwood galactoglucomannan (GGM), with nine showing strong responses in the liquid culture. Trichoderma viride, Penicillium rotoruae, and Amorphotheca resinae showed highest B-mannanase, B-mannosidase, and a-galactosidase activities. P. rotoruae demonstrated superior main chain cleaving enzyme activities, while A. resinae excelled in the side chain cleaving activity. The crude enzyme of P. rotoruae was evaluated on two Pinus radiata substrates. Using soluble GGM, P. rotoruae released 34.3% monomeric sugars (32.1 g/L reducing sugars), outperforming commercial CTec-2 (22.9% and 23.2 g/L respectively). Co-application of CTec-2 with P. rotoruae enzymes increased monomeric sugar yield to 56.3%, with galactose, mannose, and glucose increasing 20-, 3.6-, and 2.2-fold respectively. Using insoluble pulp, co-application yielded 88% of monomeric sugars (20.2 g/L reducing sugars) representing an increase of 20% soluble sugars relative to CTec-2 used alone. Techno-economic analysis indicated an increase in annual EBITDA, a positive ROCE and sugar cost savings of NZD 125/t demonstrating significant economic potential for softwood biorefineries. | |

A number of biomass processing plants that use torrefaction technology are coming up globally as this technology advances from several years of pilot and laboratory research studies to commercialization. However, continued and sustainable growth of biomass torrefaction industry hinges on the accessibility to critical technology information by decision makers especially on process efficiency measurement. This study attempts to organize and put together critical process efficiency measurement information about torrefaction technologies and later zeroes on one specific torrefaction technology called the superheated steam (SHS) torrefaction technology. The study focusses on different torrefaction technologies' applicability to processing bush encroacher and invasive bush species commonly found in Southern Africa. The study includes (a) a brief and general review of torrefaction processing plant performance metrics (b) a collection of plant and product performance information pertaining to a case study that employed SHS torrefaction technology on encroacher and invasive bush species of Southern Africa. The main objective of this study is to disseminate knowledge that can be useful in advancing SHS torrefaction technology towards addressing bush encroachment related issues, while fighting climate change through the production of renewable solid biofuels and biochemicals from these bushy woods. The review established that SHS torrefaction of Southern African encroacher and invasive bushes is technically feasible although additional optimization studies are required to prove commercial viability and improve competitiveness of the technology over fossil based processes and products. | |

In this work we aimed to increase the food potential of UK pasture by coupling targeted mechanochemical processing and novel biotechnology to convert silage into edible protein and lipid fractions. To this end, the water-soluble protein and vitamins were extracted from silage using a twin-screw extruder at room temperature. The extrusion of the silage was optimized in water with no additional chemicals. Under optimal conditions, 22 wt% of the silage was solubilized, with this fraction containing 52% of the protein present from the original material. The protein contained key essential amino acids with a profile similar to soy protein. Vitamins B1, B2, B3 (nicotinamide and nicotinic acid) and B6 (pyridoxine, pyridoxal and pyridoxamine) were also extracted. The resulting solids from the extruder, which contained further insoluble protein and the carbohydrates from the silage, were then depolymerized and used to culture the oleaginous yeast Metschnikowia pulcherrima producing further mycoprotein and lipid from the system. The mycoprotein contained a balanced amount of vital amino acids, while the yeast lipid had a fatty acid profile containing high levels of monounsaturated lipids. The silage was also found to contain high value lipids, rich in omega-6 linolenic acid. The work presented here represents a preliminary study but highlights the possibility of extracting edible nutrients from grass feasibly, with the potential to make UK agriculture far more resilient and sustainable. | |

Sugarcane is a globally important C4 crop traditionally bred for sucrose yield. However, its potential as a bioenergy crop depends on understanding lignocellulosic quality across developmental stages and environments. This study investigates the variability in fibre composition and theoretical digestibility among 17 sugarcane genotypes grown at two contrasting locations in northern Queensland. Plants were sampled at maximum vegetative growth and at peak sucrose accumulation. Fibre traits, including glucan, xylan, and lignin content, were quantified, and digestibility was estimated using cell wall composition ratios. The results revealed that digestibility declined with plant age, primarily due to increased lignin and xylan deposition. However, several genotypes maintained relatively high digestibility even at later stages. The study also identified substantial genotype-environment interactions influencing biomass quality. These findings suggest that harvesting sugarcane earlier in the cropping cycle, particularly when sucrose is not the main product, could improve fibre digestibility and biomass yield per unit time. This supports the use of sugarcane in circular bioeconomy systems and highlights opportunities for developing dual-purpose cropping strategies that align with sustainability goals. | |

This investigation explores the enhancement of CH4 generation in anaerobic digesters (AD) via in-situ renewable hydrogen injection utilising four exotic crop wastes and a crop (five feedstocks). The substrates are yam, cassava, and cocoyam peel (YP, CP and CYP), rice husk (RH) and finger millet seeds (FMS). Biomethane Potential (BMP) Tests, followed by AD experiments with food waste inoculum (FWI), were conducted in triplicate under mesophilic conditions (37 C), utilising an anaerobic model (ANM) test rig. The last phase of the experimental campaign is bio-methanation to upgrade CH4 purity. CYP and YP showed 233% and 81.5% higher gas yields, respectively, with CH4 content improvements up to 38.5%. However, CP emerged as the optimal feedstock, hence the primary substrate utilised in the AD, supporting hydrogenotrophic methanogenesis (HM) and CO2 to CH4 conversion. Consequently, MATLAB-based kinetic modelling confirmed the Richard equation as the best fit predictor. The novelty of this study lies in the innovative incorporation of in-situ H2 injection (0.67 ml/min), bubble mixing and mass transfer to enhance CH4 from tropical crop waste (cassava peel), a widely available yet underutilised feedstock specific to Plateau State, Nigeria. Additionally, integrating computational fluid dynamics (CFD) and bioprocess kinetic modelling provides a comprehensive framework for understanding the parameterisation and optimising system dynamics. This consolidates the research contribution to the experimental optimisation of decentralised biogas systems, facilitating sustainable energy solutions for pipeline quality in tropical regions. | |

Biobased materials are developed and utilized to reduce dependence on petroleum-based resources, protect the environment and reduce carbon emissions. Meanwhile, chemical recycling of thermosetting materials is an emerging strategy to increase the added value of post-consumer waste. Nevertheless, most thermosets have proved difficult to recycle due to the high stability of their crosslinked structure. Vitrimers, crosslinked by dynamic chemical bonds, are the perfect solution to recycling problems. Here, we report lignin-based vitrimers prepared by imine chemistry. First, aldehyde-modified lignin was successfully prepared by treating OH functionalized lignin with a dialdehyde via an acetalization reaction. The modified lignin acts as both a hard segment and crosslinker and the soft segment is a fatty acid diamine (Priamine (TM) 1075), which is chemically crosslinked via imine chemistry. The mechanical properties of lignin-based vitrimers (LPs) with more than 81.4% biobased content can be adjusted by blending the ratio of hard to soft segments. The resulting imine bond in LPs is highly dynamic at elevated temperatures (LP-40%, Ea = 49.6 kJ mol-1) allowing the material to be thermally recycled three cycles via imine metathesis and transimination without any catalyst. Unique hydrolytic properties of the imine bond endow the material with chemical recycling properties under acidic conditions (LP-40%, 62.0% tensile stress recovered). A potential application for this work is a coating, which can be prepared by hot pressing. In addition to the excellent coating properties, the LP coatings also possess thermal repairable, self-cleaning, removable, and degradable properties, which are not available with conventional coatings.The successful integration of biomass material (lignin) and the concept of dynamic imine bonds has led to the development of lignin-based vitrimers. These materials hold promise for applications in repairable and UV-shielding coatings. | |

Hydrothermal carbonization (HTC) research has mainly focused on primary char production, with limited attention to secondary char, which is formed through polymerization and condensation of dissolved organic compounds in the liquid phase. This research aims to address this gap via an experimental investigation of the impact of stirring on the mass and carbon balance of HTC reaction products, surface functional groups, and surface morphology of secondary char, using fructose as a model compound. A 3D hydrodynamic simulation model was developed for a two-liter HTC stirred reactor. The experimental results indicated that stirring did not significantly influence the pH, mass, carbon balance, and surface functional groups of secondary char produced under the range of experimental conditions (180 C, 10% biomass to water (B/W) ratio, and a residence time of 0-120 min) studied. Nonetheless, it was observed that a stirring rate of 200 rpm influenced the morphology and shape of the secondary char microspheres, leading to a significant increase in their size i.e., from 1-2 um in unstirred conditions compared with 70 um at a stirring rate of 200 rpm. This increase in size was attributed to the aggregation of microspheres into irregular aggregates at stirring rates > 65 rpm and residence times > 1 h. The hydrodynamic model revealed that high turbulence of Re > 104 and velocities > 0.17 m s-1 correlated with regions of secondary char formation, emphasizing their role in particle aggregation. Particle aggregation is significant above a stirring rate of 65 rpm, which corresponds to the onset of turbulent flow in the reactor. Finally, a mechanism is proposed, based on reactor hydrodynamics under stirred conditions, that explains secondary char deposition on the reactor walls and stirrer. | |

Lignocellulosic residues (LRs) are one of the most abundant wastes produced worldwide. Nevertheless, unlocking the full energy potential from LRs for biofuel production is limited by their complex structure. This study investigated the effect of N-methylmorpholine N-oxide (NMMO) pretreatment on almond shell (AS), spent coffee grounds (SCG), and hazelnut skin (HS) to improve their bioconversion to methane. The pretreatment was performed using a 73% NMMO solution heated at 120 C for 1, 3, and 5 h. The baseline methane productions achieved from raw AS, SCG, and HS were 54.7 (+/- 5.3), 337.4 (+/- 16.5), and 265.4 (+/- 10.4) mL CH4/g VS, respectively. The NMMO pretreatment enhanced the methane potential of AS up to 58%, although no changes in chemical composition and external surface were observed after pretreatment. Opposite to this, pretreated SCG showed increased porosity (up to 63%) and a higher sugar percentage (up to 27%) after pretreatment despite failing to increase methane production. All pretreatment conditions were effective on HS, achieving the highest methane production of 400.4 (+/- 9.5) mL CH4/g VS after 5 h pretreatment. The enhanced methane production was due to the increased sugar percentage (up to 112%), lignin removal (up to 29%), and loss of inhibitory compounds during the pretreatment. An energy assessment revealed that the NMMO pretreatment is an attractive technology to be implemented on an industrial scale for energy recovery from HS residues. | |

Grass, a low-cost lignocellulosic feedstock with relatively low lignin content, serves as a potential carbon source for microbial processes due to its polymeric sugar content. However, converting carbohydrates into monomeric sugars presents challenges due to complex lignocellulosic matrix. In this study, a mixture of perennial ryegrass and white clover (RG) was pretreated with alkaline before being enzymatically hydrolysed for use as a fermentable sugar source for the oleaginous yeast Metschnikowia pulcherrima. The dilute alkaline pretreatment approach resulted in a 3 times improvement in the conversion of RG, yielding a fermentable sugar concentration of 56.5 g/L. The yeast exhibited a growth yield (Ym/m) of 0.47, producing 23.7 g/L of dry cell weight at 20 C over 140 hours, with a lipid content of 37 % with a similar composition to high oleic palm oil. These findings suggest that RG can be utilised for formulating an oleaginous yeast medium containing the necessary nutrients. | |

This study proposes a chemical recycling pathway for valorizing the cellulosic component of municipal waste streams such as textile, cleaning wipes, corrugated cardboard, contaminated cardboard (i.e. a pizza box), paper-plastic laminate (PPL) coffee cups and cigarette butts (CBs). The goal of this study is to establish an experimental procedure that allows to test a broad range of cellulose-containing waste materials, laying the groundwork for commercial deployment of their chemical recycling. The cellulose contained in these materials is transformed into 5-chloromethylfurfural (CMF), a precursor for bio-based plastics, without affecting the plastic counterpart (if present). We employ a biphasic system concept using aqueous HCl solutions for CMF formation and in situ extraction from the reaction medium using immiscible organic solvents, enabling straightforward product separation. This method allows to hydrolyze cellulosic materials from waste without affecting PET or polyolefin plastic also present, facilitating the subsequent recycling of this plastic as well. This study serves as a foundation to assess the feasibility of using cellulose-containing waste streams for chemical recycling and to offer recommendations on selecting optimal reaction procedures. | |

Brewer's spent grain (BSG) contains a large fraction of proteins, lignin, and carbohydrates. However, its heterogeneous composition limits its use in the food industry. The current work evaluated a cascade process for fractionation of these compounds. Two different thermally diluted acid pretreatments prior to enzymatic hydrolysis steps were evaluated. Condition 1 (C1) corresponded to 0.49% (v/v) HCl at 87.7 C for 92.7 min, and C2 used 0.80% HCl at 121.0 C for 142 min. Three different solid fractions were obtained for each condition, a fine solid (FS) (particle size <25?m), a coarse solid (CS) rich in protein and fiber, and an alkaline solid (AS) rich in fiber. The fractions had water retention capacities between 4.0 and 8.8 gH2O/gTS. The highest protein content was obtained for C1-FS (31.5% w/w), and the highest total fiber content for C2-AS (>80%). Some of those fractions have characteristics similar to those of current market ingredients used in the food industry. | |

Haemorrhage control during surgery and following traumatic injury remains a critical, life-saving challenge. Cellulose products are already employed in commercially available haemostatic dressings. This work explores sourcing cellulose from sugarcane trash pulp to produce micro- and nanosized fibres with hydroxyl, carboxylic acid, and trimethylamine functional groups, resulting in either positive or negative surface charges. This paper assesses the influence of these fibres on multiple blood clotting parameters in both dispersed solutions and dry gauze applications. In vitro blood clotting studies demonstrated the significant haemostatic potential of cellulose fibres derived from sugarcane waste to initiate clotting. Plasma absorbance assays showed that the 0.25 mg/mL cellulose microfibre dispersion had the highest clotting performance. It was observed that no single property of surface charge, functionality, or fibre morphology exclusively controlled the clotting initiation measured. Instead, a combination of these factors affected clot formation, with negatively charged cellulose microfibres comprising hydroxyl surface groups providing the most promising result, accelerating the coagulation cascade mechanism by 67% compared to the endogenous activity. This difference in clot initiation shows the potential for the non-wood agricultural waste source of cellulose in haemostatic wound healing applications, contributing to the broader understanding of cellulose-based materials' versatility and their applications in biomedicine. | |

Monosaccharides such as L-arabinose (Ara) and D-tagatose (derived from D-galactose, Gal) are low-calorie sweeteners associated with improved glycaemic and insulin control compared to disaccharides such as sucrose. However, alternative sources and better sugar-sugar separation methods are needed to improve the sustainability and economics of their production. Here, these sugars were obtained from purified and ultrafiltered compression screw pressate (CSP) of thermo-mechanical pulping of softwood (Pinus radiata) and orange peels (OPs). Ba- substituted zeolite X (BaX) molecular sieves showed superior separation performance of Ara from other sugars compared to conventional Ca-form ion exchange resin. To facilitate subsequent separation of sugars, OP hydrolysates were fermented to leave just Ara and Gal, while OP pectin was hydrolysed to generate a Gal-rich mixture. Overall, BaX has good potential for separating Ara from Ara-rich hydrolysates containing several different sugars. It is also suited for separating Ara and another monosaccharide such as Gal or Xyl in the absence of other sugars. | |

Value added lignin rich waste sludges from biorefinery processes are, as yet untapped valuable feedstocks that can be reformed into clean, high quality solid fuels. By water washing sludges produced from base hydrolyzed waste, a material stripped of water-soluble alkali and alkaline earth metals (ash) can be obtained. This work shows how leached bagasse, barley and wheat straw sludges can be valorised into clean, low ash solid biofuels that can be used to supplement global energy demands. Repurposed lignin rich sludges of 1.00-2.00mm particle size feedstocks were found to exhibit calorific values +17.3%, +16.8% and +11.7% for bagasse, wheat, and barley straw sludges, respectively higher than their untreated waste counterparts. Additionally, by employing densification in the absence of a binder, <0.25mm particles of leached sludge feedstocks were found to experience 16.0% (bagasse), 12.0% (wheat) and 4.0% (barley) increases to their calorific values. This provides options for sustained energy from waste production and consumption campaigns, diversifying feedstock options for green solid fuels | |

Radiocarbon (D14C) measurements of nonstructural carbon enable inference on the age and turnover time of stored photosynthate (e.g., sugars, starch), of which the largest pool in trees resides in the main bole. Because of potential issues with extraction-based methods, we introduce an incubation method to capture the D14C of nonstructural carbon via respired CO2. In this study, we compared the D14C obtained from these incubations with D14C from a well-established extraction method, using increment cores from a mature trembling aspen (Populus tremuloides Michx). To understand any potential D14C disagreement, the yields from both methods were also benchmarked against the phenol-sulfuric acid concentration assay. We found incubations captured less than 100% of measured sugar and starch carbon, with recovery ranging from ~3% in heartwood to 85% in shallow sapwood. However, extractions universally over-yielded (mean 273 +/- 101% expected sugar carbon; as high as 480%), where sugars represented less than half of extracted soluble carbon, indicating very poor specificity. Although the separation of soluble and insoluble nonstructural carbon is ostensibly a strength of extraction-based methods, there was also evidence of poor separation of these two fractions in extractions. The D14C of respired CO2 and D14C from extractions were similar in the sapwood, whereas extractions resulted in comparatively higher D14C (older carbon) in heartwood and bark. Because yield and D14C discrepancies were largest in old tissues, incubations may better capture the D14C of nonstructural carbon that is actually metabolically available. That is, we suggest extractions include metabolically irrelevant carbon from dead tissues or cells, as well as carbon that is neither sugar nor starch. In contrast, nonstructural carbon captured by extractions must be respired to be measured. We thus suggest incubations of live tissues are a potentially viable, inexpensive and versatile method to study the D14C of metabolically relevant (available) nonstructural carbon. | |

This study explores the hydroxycinnamic acid extraction from prairie biomass as a potential value-added pretreatment for enhancing the performance of anaerobic digestion. Pretreatment increased the biomethane potential of prairie biomass by 33 %; when the extraction residue was left on the biomass, the biomethane potential increased by 100 %. When the treated biomass was co-digested with manure, a 134 % and 25 % increase in methane productivity and methane content was obtained, respectively, relative to raw biomass co-digested with manure. Hydroxycinnamic acid extraction also improved anaerobic digestion performance under biochar supplementation and liquid digestate recirculation conditions. Lastly, the extraction process was optimized for hydroxycinnamic acid yield. It was found that increases in treatment temperature and time could further increase yield by 5 %. Collectively, the results show hydroxycinnamic acid extraction can be used as a highly effective pretreatment for improving the anaerobic digestion of prairie biomass. | |

Although industrial hydrothermal carbonization (HTC) uses wet feedstock, lab-scale studies tend to dry the feedstock under the assumption that the rehydration of the feedstock would restore its original properties. To the best of our knowledge, this assumption has not been thoroughly examined at the lab scale; therefore, its investigation is crucial to prevent any discrepancies that might affect the upscaling of HTC. This research aims to examine the effects of pre-drying biomass by comparing it to the use of wet biomass in HTC experiments, employing three different types of biomass (rejected tomatoes, rejected apples, and digestate). Additionally, the study investigates the influence of stirring on pre-dried and wet biomass under the selected HTC conditions. The results indicate a substantial disparity in studied hydrochar properties when using pre-dried biomass compared to wet biomass. For pre-dried biomass, there is a tendency for an increase in mass yield and solid carbon yield in most examined samples (5-10% dry basis) compared to the wet biomass. Regarding functional groups, wet tomatoes and apples exhibit more pronounced peaks than pre-dried samples. Conversely, digestate shows similar spectra across all examined scenarios. The effect of stirring appears insignificant for most of the studied scenarios; nevertheless, it reduced dehydration and decarboxylation reactions during HTC. | |

A dried dairy processing sludge (sludge from wastewater treatment of an effluent from a milk processing plant) was pyrolysed in a single-particle reactor at different temperatures from 400 C to 900 C. NH3 and HCN were measured online and offline by means of FTIR as well as by cumulative sampling in impinger bottles (in 0.05 M H2SO4 and 1 M NaOH, respectively) and analysed by photometric method. NO and NO2 were measured online using a nitric oxide analyser while N2O was measured by FTIR. Nitrogen (N) in the sludge and in the remaining char, char-N, was determined. Moreover, tar content in pyrolysis gas was measured and tar-N was determined. The results with respect to N mass balance closure are discussed. The different measurements techniques are compared. For pyrolysis at 520 and 700 nitrogen in the gas phase was mainly contained as N2 (36 % and 40 % respectively), followed by NH3 (15 % and 18 %), tar-N (10 % and 9 %), HCN (1 % and 3 %), NO (1 %) and NO2 (0.2 %). The dairy processing sludge has very specific properties with organic-N present predominantly as proteins and a high content of inherent Ca. These characteristics affected the distribution of N. The amount of char-N was higher while the amount of tar-N lower than for sewage sludge from literature, at comparable pyrolysis temperature. | |

The relationship between metabolic changes occurring in the developing internodes of sugarcane and the final yield and sugar characteristics is poorly understood due to the lack of integration between phenotypic and metabolic data. To address this issue, a study was conducted where sugarcane metabolism was modeled based on the measurement of cellular components in the top internodes, at two stages of crop development. The study also looked at the effects of Trinexapac-ethyl (Moddus) on growth inhibition. The metabolome was measured using GC-analysis, while LC-MS/MS was used to measure proteome changes in the developing internodes. These data were then integrated with the metabolic rates. Regardless of the growth rate, internode elongation was restricted to the top five internodes. In contrast, sucrose and lignin accumulation was sensitive to the growth rate. Crossover plots showed that sucrose accumulation only occurred once the cell wall synthesis had slowed down. These data suggest that sucrose accumulation controlled a reduction in sucrose breakdown for metabolic activity and a reduction in demand for carbon for cell wall polysaccharide synthesis. This study also found that nucleotide sugar metabolism appears to be a key regulator in regulating carbon flow during internode development. | |

Considering the current transition to biobased carbon sources and the search for viable extraction procedures, the microwave-assisted solubilization of seaweed biomass was explored. Hereto, the brown North Sea native species Ascophyllum nodosum was processed using water as green extraction solvent. Response surface methodology was used to determine the best solubilization conditions towards maximizing the solubilization efficiency and minimizing the applied energy per mass of solubilized seaweed by varying (i) temperature, (ii) time and (iii) solid to liquid ratio (S/L). It was found that a temperature of 120 C, a processing time of 15?min and a 1.03 w:v S/L are most suitable to achieve the pre-set criteria. Concurrently, mass balances were developed with respect to total lipid, polysaccharide, protein, mineral and heavy metal contents. Moreover, zeta potential measurements were performed to link the obtained values and the antimicrobial characteristics of the extracts. Finally, antimicrobial tests on S. aureus and E. coli were conducted and with results indicating up to 97?% inhibition of bacterial growth after 8?h, antimicrobial characteristics were indeed observed. | |

The importance of reducing the strong dependence of the chemical industry on fossil feedstock is no longer a debate. Above-the-ground carbon is abundant, but scalable technologies to supply alternatives to fossil-fuel-derived chemicals and/or materials at the world scale are still not available. Lignocellulosic biomass is the most available carbon source, and a first requirement for its valorization is the complete saccharification of its sugar-bearing components. HCl-based technologies can achieve this at 20 C and ambient pressure. These principles were disclosed in the 1920s, but the inability to economically separate sugars from acids impeded its commercialization. Avantium Chemicals B.V. developed a modern version of this 'Bergius' highly concentrated acid hydrolysis, in which the saccharides in HCl are transformed into furanics without any prior purification, in particular, to 5-(chloromethyl)furfural (CMF). Saccharide conversion to CMF was developed by Mascal in the early 2000s. CMF is extracted in situ using immiscible organic solvents, allowing for an easy product separation. This study not only targets to investigate the viability and optimization of this integrated process but also aims to predict the outcome of the CMF formation reaction by applying design of experiment techniques from the hydrolyzed saccharides varying a broad range of reaction parameters. | |

The Organic Fraction of Municipal Solid Waste (OFMSW) contains paper and cardboard, an attractive cellulosic feedstock for bioethanol production. Waste paper/cardboard (WPC) was subjected to mild acid treatment in solids loadings from 20 to 27.5 %. Different doses of commercial enzyme cocktail and various adjuvants facilitating enzymatic saccharification were tested. Enzyme dosing of 3.75 FPU/g fiber with very slow fed-batch saccharification of 27.5 % (w/v) solids from model lignin-free paper pulp resulted in 12.6 % (w/v) total sugar after 74 h. Use of cheap non-catalytic waste protein adjuvants including Soymeal, Protisyr, Feather meal strongly improved enzymatic saccharification and reduced the overall process cost by reducing commercial enzyme dosing. After fermentation with the industrial yeast strain BMD44 (Cellusec 1.0) an ethanol titer of 5.77 % (v/v) was obtained using a reduced enzyme loading of 2.5 FPU/g of actual industrial WPC fiber. These results show the potential of economically profitable second-generation bioethanol production with WPC fiber. | |

This study tested the hypothesis that post-harvest hot water blanching improves the chemical composition, mainly mineral and carbohydrate contents, and in vitro digestibility of two predominant brown macroalgae, Ascophyllum nodosum (AN) and Fucus vesiculosus (FV), as feed ingredients for monogastric and ruminant animals. Low-temperature water blanching (LTB; 40 C for 5 min) had minor impacts on macroalgal chemical composition and in vitro digestibility. Conversely, high-temperature water blanching (HTB; 80 C for 5 min) effectively reduced total ash and specific elements, including sodium, potassium, iodine, and arsenic, by ~ 25�73% compared to unblanched algal biomass (more prominently in FV). The HTB raised total sugar contents by ~ 25% in FV, markedly elevating uronic acids (~60%) and glucans (~33%). However, HTB reduced mannitol (>50%) and enhanced total polyphenol extractability in both macroalgae. The HTB diminished ~ 8% of in vitro dry matter or organic matter digestibility and 26% of crude protein (CP) digestibility of both macroalgae for monogastric animals and of FV for ruminants (particularly of CP by ~ 42%). Those reduced digestibilities were associated with enriched fibre, uronic acids, total polyphenols, and declined mannitol in the HT-blanched macroalgal biomass. Our findings suggest that hot-water blanching can be an efficient technique to optimise the elemental composition of two fucoid algae, but the altered sugar and complex carbohydrate compositions may impair their digestibility. Future studies should identify appropriate post-harvest processing techniques for brown macroalgae that can optimise both nutritional composition and digestibility along with favourable impacts on feed utilisation and animal performance. | |

Lignocellulosic biomass plays a vital role in the global shift away from the utilisation of non-renewable petrochemical resources. An emerging class of biomass-derived material is nanocellulose, which are typically generated from the deconstruction of cellulose bundles within the cell wall of terrestrial and aquatic plants, either in the form of cellulose nanocrystals (CNCs) or cellulose nanofibres (CNFs). However, the utilisation of biomass has an inherent challenge associated with product variability, both in terms of the starting feedstock properties, the wide range of processing routes available to generate nanocellulose, and the fabrication of nanocellulose into a diverse range of different product formats. As a result, it is difficult to accurately characterise and benchmark the wide variety of nanocellulose materials described within the literature. To address this challenge, this study presents a threefold benchmarking assessment of CNF-based material, including: (1) CNFs generated from different biomass sources (sorghum, banana, sugarcane, spinifex, and softwood); (2) CNFs generated through different mechanical processing methods (Silverson mixing, twin-screw extrusion, bead milling, and high pressure homogenisation); and (3) Energy-standardised nanopaper mechanical performance presented within applicable literature studies. The biomass benchmarking study highlighted sorghum and banana stem as comparatively sustainable biomass feedstock, while the mechanical process benchmarking study highlighted twin-screw extrusion as a promising fibrillation method with relatively low energy consumption. Lastly, the nanopaper benchmarking study aided in the visualisation of the nanopaper research landscape. Overall, sample benchmarking in this manner provides greater insight into the mechanisms driving nanocellulose material performance and processing sustainability. | |

Biochar is an engineered carbon-rich substance used for soil improvement, environmental management, and other diverse applications. To date, the understanding of how biomass affects biochar microstructure has been limited due to the complexity of analysis involved in tracing the changes in the physical structure of biomass as it undergoes thermochemical conversion. In this study, we used synchrotron x-ray micro-tomography to visualize changes in the internal structure of biochar from diverse feedstock (miscanthus straw pellets, wheat straw pellets, oilseed rape straw pellets, and rice husk) during pyrolysis by collecting a sequence of 3D scans at 50 C intervals during progressive heating from 50 C to 800 C. The results show a strong dependence of biochar porosity on feedstock as well as pyrolysis temperature, with observed porosity in the range of 7.41-60.56%. Our results show that the porosity, total surface area, pore volume, and equivalent diameter of the largest pore increases with increasing pyrolysis temperature up to about 550 C. The most dramatic development of pore structure occurred in the temperature range of 350-450 C. This understanding is pivotal for optimizing biochar's properties for specific applications in soil improvement, environmental management, and beyond. By elucidating the nuanced variations in biochar's physical characteristics across different production temperatures and feedstocks, this research advances the practical application of biochar, offering significant benefits in agricultural, environmental, and engineering contexts. | |

Dairy processing sludge (DPS) is a byproduct generated in wastewater treatment plants located in dairy (milk) processing companies (waste activated sludge). DPS presents challenges in terms of its management (as biosolids) due to its high moisture content, prolonged storage required, uncontrolled nutrient loss and accumulation of certain substances in soil in the proximity of dairy companies. This study investigates the potential of hydrothermal carbonization (HTC) for recovery of nutrients in the form of solid hydrochar (biochar) produced from DPS originating from four different dairy processing companies. The HTC tests were carried out at 160 C, 180 C, 200 C and 220 C, and a residence time of 1h. The elemental properties of hydrochars (biochars), the content of primary and secondary nutrients, as well as contaminants were examined. The transformation of phosphorus in DPS during HTC was investigated. The fraction of plant available phosphorus was determined. The properties of hydrochar (biochar) were compared against the European Union Fertilizing Products Regulation. The findings of this study demonstrate that the content of nutrient in hydrochars (biochars) meet the requirements for organo-mineral fertilizer with nitrogen and phosphorus as the declared nutrients (13.9-26.7%). Further research on plant growth and field tests are needed to fully assess the agronomic potential of HTC hydrochar (biochar). | |

A novel thermo-mechanical pulping (TMP) process has been developed to produce a by-product rich in high-molecular weight (MW) hemicelluloses, a potential raw material for barrier coatings and films. This process uses prehydrolysis to solubilise the hemicelluloses followed by chip compression to separate the soluble material from the wood matrix. The pressate from the chip compression stage was dark-coloured and had a high content of high-MW hemicelluloses and lignin. However, isolating the high-MW material from the pressate directly by ultrafiltration was not feasible because of membrane fouling by dissolved lignin and wood extractives, while coloured impurities are undesirable for many potential applications. To solve these problems the pressate was purified using XAD adsorbent resin to remove low-MW lignin, extractives and colour. Ultrafiltration of the purified pressate yielded lightly coloured high-MW hemicellulose with a low content of lignin and well suited for barrier films and coatings. | |

Disposal of waste-activated sludge [dairy processing sludge, (DPS)] from wastewater treatment plants located in milk processing companies is an increasing concern. DPS is usually applied to farmlands in the vicinity of the dairy companies. This practice is becoming unsustainable due to uncontrolled nutrient loss and potential soil contamination. We propose to recover nutrients in the form of biochar. This paper examines the properties of biochars obtained from slow pyrolysis of DPS. DPS samples were pyrolyzed at laboratory and pilot scale at 600 and 700 C. The elemental properties of biochars, the content of primary and secondary nutrients, as well as contaminants were examined and compared against the European Union Fertilizing Products Regulation. The biochars meet the specified limits for hydrogen-to-organic carbon ratio, chloride, and polycyclic aromatic hydrocarbons intended for gasification and pyrolysis component category materials. In six out of eight biochars, the content of phosphorus (P) as a single declared nutrient and the level of contaminants meet those required for an organo-mineral fertilizer. Only two biochars meet the required concentrations of nitrogen, phosphorus, and potassium. A minimum solid content of 30% in DPS is required to make the process of biochar production energetically sustainable. | |

Polymer materials today face significant challenges, notably the utilization of green and low-carbon feedstock, the development of eco-friendly preparation processes, and effective material recycling. A promising solution to these challenges lies in the direct synthesis of covalent adaptable networks (CANs) from biomass sources, like lignin. However, the development of unmodified lignin CANs via catalyst-free methods has been a challenging task. Here, we report the successful preparation of lignin-based CANs (TERs) via phthalate monoester transesterification. In this system, lignin (PB1000) serves as hard segment and crosslinker, while the soft segment consists of a biomass diol (PripolTM 2033). By blending the ratio of hard to soft segments, we were able to tune the mechanical properties of the TERs (with lignin content ranging from 10 to 50 wt% and crosslink density increasing from 3600 mol/m3 to 47900 mol/m3). Monoester bonds within the TERs are highly dynamic at elevated temperatures (with an activation energy of 169.2 kJ mol-1), facilitating material recycling without the need for catalysts. Furthermore, TERs can be chemically recycled via alkaline solutions at 80 C. Notably, we demonstrate a potential application for this work in the form of a TER-based adhesive. In addition to its excellent adhesion properties, the TER adhesive exhibits thermal repair ability, removability, and degradability properties. This work provides a green and sustainable approach towards tackling the challenges associated with recycling of thermoset plastics. | |