Services for the Analysis of Oligosaccharides

Background

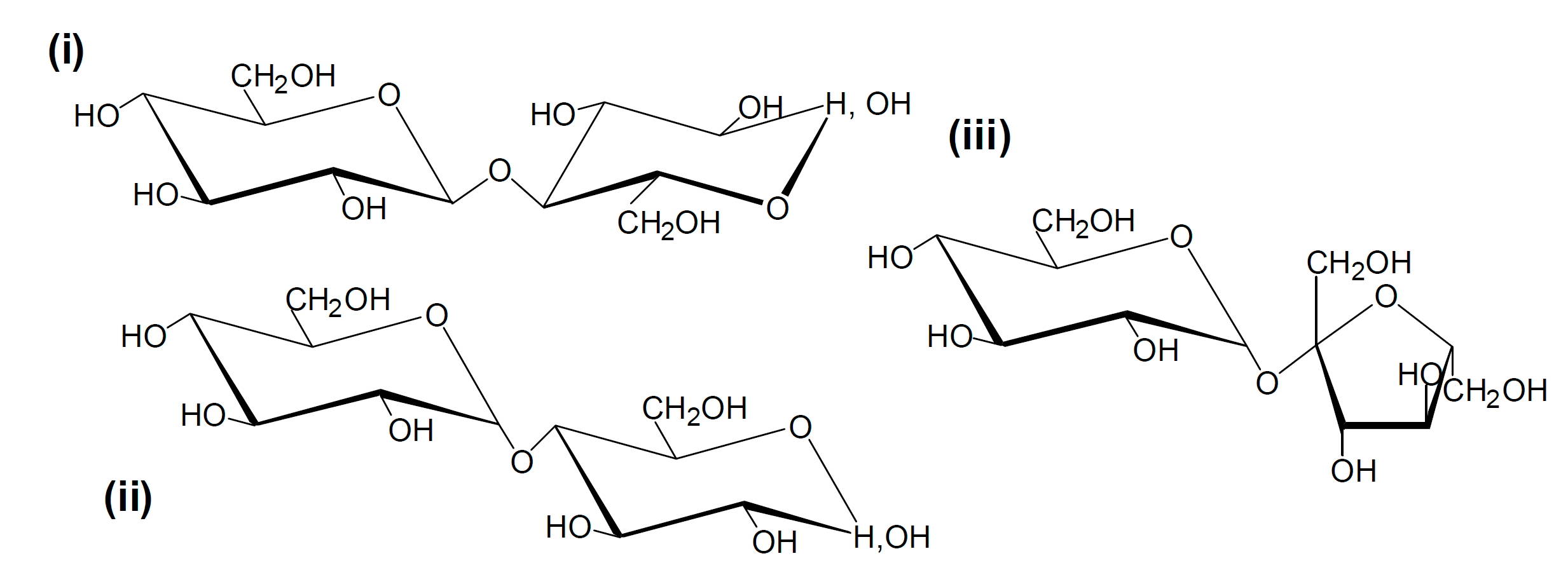

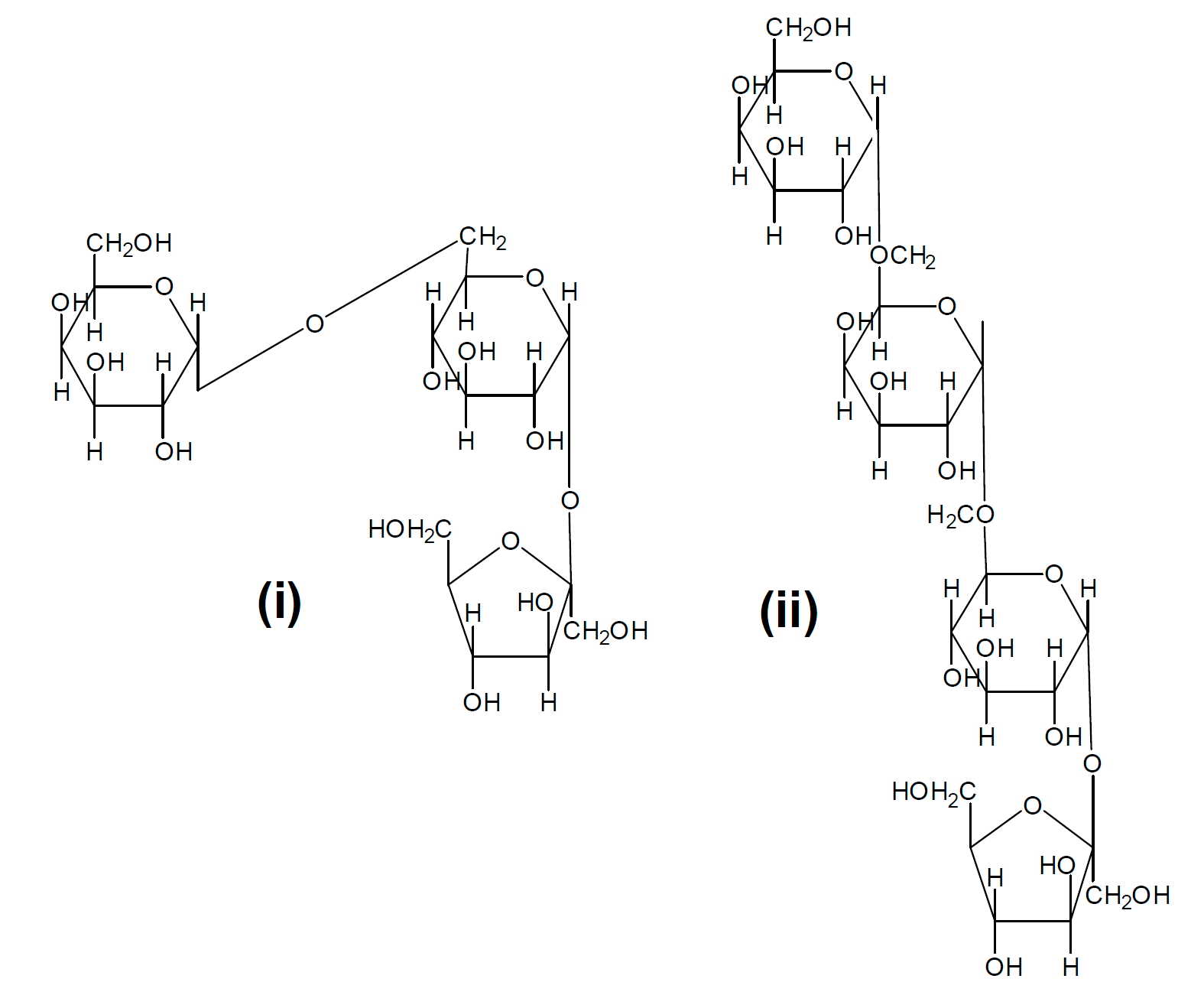

1. Monosaccharides - a single sugar unit (e.g glucose, xylose, and fructose).

2. Oligosaccharides - up to ten monosaccharide residues joined together by glycosidic linkages.

3. Polysaccharides - generally considered to be polymers of more than ten monosaccharide residues. Examples include cellulose, hemicellulose, and starch.

Request a QuoteOligomers Analysis

Oligosaccharides in Pre-Treatment and Hydrolysis Liquids

Oligosaccharides in Bio-Oil

Please click here to read more about bio-oil and the analysis methods that we use to characterise it.

Request a QuoteBio-Oil Oligomers

Direct Analysis of Oligosaccharides

If you would like us to directly determine other oligosaccharides then this may be possible depending on whether a suitable chromatography method for separation and appropriate chemical standards for those oligosaccharides are available. Please get in touch with us to discuss this.

Determination of the Proportions of Each Sugar in the Oligomeric Form

Firstly, the liquid is analysed using our ion chromatography system for the free monosaccharides and disaccharides in solution, just as in package P21 - Sugars in Solution.

Then we subject the liquid to a mild form of acid hydrolysis involving 4% sulphuric acid and 1 hour in an autoclave at 121 degrees Celcius. These conditions will break apart any oligosaccharides into their constituent monosaccharide units.

The liquid is subsequently filtered and analysed again on our IC system, to determine the amounts of various monosaccharides, after correction for any losses in sugars associated with the hydrolysis process. For each monosaccharide there will now be two values, the concentration prior to hydrolysis and that after hydrolysis.

The constituents determined in analysis package P13 - Sugars and Oligosaccharides in Solution are detailed below. In our reports for P13 we report the pre-hydrolysis, post-hydrolysis and oligomeric concentrations of each sugar.

As with P13, analysis package P62 then involves the acid hydrolysis of the liquid to calculate the oligomeric composition. However, in this case the anhydrosugars will be hydrolysed to their hydrated aldose equivalents (i.e. levogluocosan and cellobiosan to glucose, mannosan to mannose, and galactosan to galactose) and we consider this in our calculations to ensure that the proportions of each sugar that are reported as being present in oligomers actually are. Analysis package P62 is detailed below:

Economic production of fermentable sugars from lignocellulosic biomass is critical for the biorefinery applications in the bioeconomy industry. This study demonstrates effective enzymatic hydrolysis of recalcitrant softwood using newly identified fungus Penicillium rotoruae. Initially, nineteen fungal isolates were screened on softwood galactoglucomannan (GGM), with nine showing strong responses in the liquid culture. Trichoderma viride, Penicillium rotoruae, and Amorphotheca resinae showed highest B-mannanase, B-mannosidase, and a-galactosidase activities. P. rotoruae demonstrated superior main chain cleaving enzyme activities, while A. resinae excelled in the side chain cleaving activity. The crude enzyme of P. rotoruae was evaluated on two Pinus radiata substrates. Using soluble GGM, P. rotoruae released 34.3% monomeric sugars (32.1 g/L reducing sugars), outperforming commercial CTec-2 (22.9% and 23.2 g/L respectively). Co-application of CTec-2 with P. rotoruae enzymes increased monomeric sugar yield to 56.3%, with galactose, mannose, and glucose increasing 20-, 3.6-, and 2.2-fold respectively. Using insoluble pulp, co-application yielded 88% of monomeric sugars (20.2 g/L reducing sugars) representing an increase of 20% soluble sugars relative to CTec-2 used alone. Techno-economic analysis indicated an increase in annual EBITDA, a positive ROCE and sugar cost savings of NZD 125/t demonstrating significant economic potential for softwood biorefineries. | |

A novel thermo-mechanical pulping (TMP) process has been developed to produce a by-product rich in high-molecular weight (MW) hemicelluloses, a potential raw material for barrier coatings and films. This process uses prehydrolysis to solubilise the hemicelluloses followed by chip compression to separate the soluble material from the wood matrix. The pressate from the chip compression stage was dark-coloured and had a high content of high-MW hemicelluloses and lignin. However, isolating the high-MW material from the pressate directly by ultrafiltration was not feasible because of membrane fouling by dissolved lignin and wood extractives, while coloured impurities are undesirable for many potential applications. To solve these problems the pressate was purified using XAD adsorbent resin to remove low-MW lignin, extractives and colour. Ultrafiltration of the purified pressate yielded lightly coloured high-MW hemicellulose with a low content of lignin and well suited for barrier films and coatings. | |

Brewers spent grains (BSGs) represent the largest quantity of solid waste from brewing, while xylooligosaccharides (XOS) produced from BSG show promising applications in food, beverage and health products. Production of XOS from a Weiss and malt BSG was scaled-up in steam explosion hydrothermal treatment using process conditions from bench-scale liquid hot water optimisations in stirred batch reactors. Three levels of moisture (15, 25 and 32% dry matter) achieved by screw press dewatering were evaluated by varying the treatment temperatures and times. Results show the highest XOS yields (73.1%) were obtained, for both BSGs, at process condition selected (180 C, 10 min) with 25% initial dry matter content. These yields were higher than reported bench-scale optimisations (61%), but obtained using 60% less water; hence, initial dry matter content was an important variable affecting XOS yield. The pilot-scale steam explosion results provide a departing point for a cost-effective commercial production of XOS from BSG. | |

BACKGROUND | |

Brewers' spent grains (BSG) make up to 85% of a brewery's solid waste, and is either sent to landfill or sold as cheap animal feed supplement. Xylo-oligosaccharides (XOS) obtained from BSG are antioxidants and prebiotics that can be used in food formulations as low-calorie sweeteners and texturisers. The effect of extremely low acid (ELA) catalysis in liquid hot water (LHW) hydrothermal treatment (HTT) was assessed using BSG with dry matter contents of 15% and 25%, achieved by dewatering using a screw press. Batch experiments at low acid loadings of 5, 12.5 and 20 mg/g dry mass and temperatures of 120, 150 and 170 C significantly affected XOS yield at both levels of dry mass considered. Maximum XOS yields of 76.4% (16.6 g/l) and 65.5% (31.7 g/l) were achieved from raw BSG and screw pressed BSG respectively, both at 170 C and using 5 mg acid/g dry mass, after 15 min and 5 min, respectively. These XOS yields were obtained with BSG containing up to 63% less water and temperatures more than 20 C lower than that reported previously. The finding confirms that ELA dosing in LHW HTT allows lowering of the required temperature that can result in a reduction of degradation products, which is especially relevant under high solid conditions. This substantial XOS production intensification through higher solid loadings in HTT not only achieved high product yield, but also provided benefits such as increased product concentrations and decreased process heat requirements. | |

Jerusalem artichoke (JA) is a crop with excellent potential for application in biorefineries. It can resist drought, pests, and diseases and can thrive well in marginal lands with little fertilizer application. The JA tubers contain considerable quantities of inulin, which is suitable for the production of inulooligosaccharides (IOS), as a high-value prebiotic, dietary fiber. In this study, five JA tuber biorefinery scenarios were simulated in Aspen Plus and further evaluated by techno-economic and sensitivity analyses. Production of IOS, proteins and animal feed was studied in scenarios A and C, applying various biorefinery configurations. Scenario B explored the option of producing only IOS and the sale of residues as animal feed. Scenarios D and E investigated the economic potential of biofuel generation from residues after IOS and protein production by generation of biogas and ethanol respectively, from residues. Based on the chosen economic indicators, scenario B resulted in the lowest minimum selling price (MSP) of 3.91 US$ kg-1 (market price 5.0 US$ kg-1) with correspondingly reduced total capital investment (TCI) and total operating cost (TOC) per mass unit produced of IOS of 18.91 and 2.59 US$ kg-1 respectively, compared with other studied scenarios. Considering the set production scale, it is more profitable when the residues are sold as animal feed instead of being converted into biofuel, due to the capital-intensive nature of the biofuel production processes. The coproduction of protein had a negative impact on the economics of the process as the associated capital and operating expenditure outweighed the associated revenue. | |

Pretreatments of lignocellulosic biomass prior to fast pyrolysis need to give a better yield and quality of pyrolysis oil and be practical to implement at a commercial scale. This study demonstrated, at a large pilot scale, that thermomechanical refining can reduce the particle size, hemicellulose content, and mineral content of pine wood chips, leading to improved yields of carbohydrate-derived chemicals on fast pyrolysis. Additionally, a hemicellulose-rich byproduct can be generated during the pretreatment for separate valorization. The impact of different presteaming times, citric acid infusion, and disc refining on the yield and composition of the pyrolysis oil was studied. Presteaming of citric acid-infused wood chips at 173 C for 3 min and refining to wood fiber proved most effective in improving the yield of pyrolysis oil organics, including the valuable biochemicals levoglucosan and hydroxyacetaldehyde, while reducing the yields of low-value char and noncondensable gases. | |

The immobilization of B-fructofuranosidase for short-chain fructooligosaccharide (scFOS) synthesis holds the potential for a more efficient use of the biocatalyst. However, the choice of carrier and immobilization technique is a key to achieving that efficiency. In this study, calcium alginate (CA), Amberlite IRA 900 (AI900) and Dowex Marathon MSA (DMM) were tested as supports for immobilizing a novel engineered B-fructofuranosidase from Aspergillus japonicus for scFOS synthesis. Several immobilization parameters were estimated to ascertain the effectiveness of the carriers in immobilizing the enzyme. The performance of the immobilized biocatalysts are compared in terms of the yield of scFOS produced and reusability. The selection of carriers and reagents was motivated by the need to ensure safety of application in the production of food-grade products. The CA and AI900 both recorded impressive immobilization yields of 82 and 62%, respectively, while the DMM recorded 47%. Enzyme immobilizations on CA, AI900 and DMM showed activity recoveries of 23, 27, and 17%, respectively. The CA, AI900 immobilized and the free enzymes recorded their highest scFOS yields of 59, 53, and 61%, respectively. The AI900 immobilized enzyme produced a consistent scFOS yield and composition for 12 batch cycles but for the CA immobilized enzyme, only 6 batch cycles gave a consistent scFOS yield. In its first record of application in scFOS production, the AI900 anion exchange resin exhibited potential as an adequate carrier for industrial application with possible savings on cost of immobilization and reduced technical difficulty. | |