Mechanical Pretreatment of Biomass

Background

Lignocellulosic Biomass

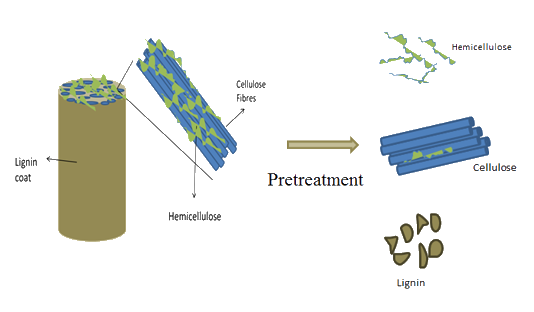

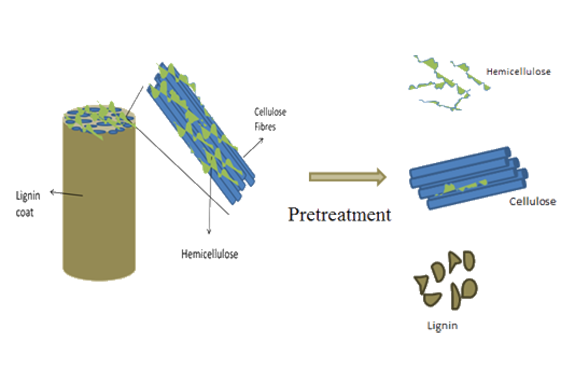

Lignocellulosic biomass is defined as a plant, or plant-derived, material that is mostly composed of cellulose, hemicellulose, and lignin. Lignocellulosic feedstocks are highly abundant, covering many biomass types including grasses, wood, energy crops (e.g. Miscanthus and coppices), agricultural residues (e.g. straws and corn stover), and municipal wastes.Lignocellulosic feedstocks are highly abundant and can often be sourced sustainably, at low cost, without leading to land-use conflicts. As a result, there is currently great interest in obtaining chemicals, fuels, and biomaterials from such biomass.

However, the hydrolysis of lignocellulosic polysaccharides is not easy and is influenced by the complex inter-associations between hemicellulose and cellulose and between these polysaccharides and lignin in the lignocellulosic matrix. In particular, the crystalline nature of much cellulose and the existence of a physical barrier of lignin surrounding the cellulose fibres are said to be major contributors to the recalcitrance of cellulose.

The mechanism of hydrolysis is further complicated by the fact that different process intensities are required for the hydrolysis of cellulose versus hemicellulose. The more intense conditions required for cellulose hydrolysis may degrade the sugars hydrolysed from hemicellulose (to products such as furfural and formic acid).

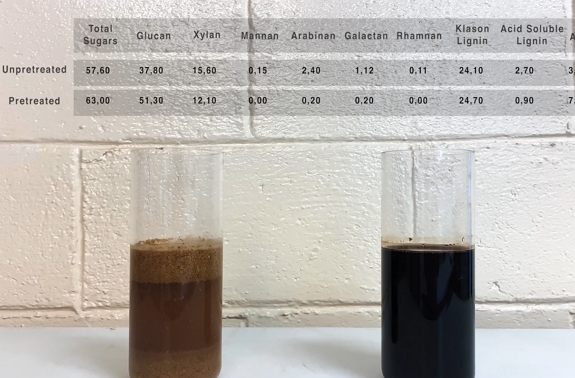

For this reason, most hydrolysis technologies employ pre-treatment processes that aim to break apart the matrix (and in particular the associations between lignin and cellulose), reduce cellulose crystallinty, and hydrolyse hemicelluloses, hence separating the hydrolysate from cellulose which can then undergo more severe/targeted treatment.

Get more info...Biomass Hydrolysis

Need for Pretreatment

For this reason, most hydrolysis technologies employ pre-treatment processes that aim to break apart the matrix (and in particular the associations between lignin and cellulose), reduce cellulose crystallinty, and hydrolyse hemicelluloses, hence separating the hydrolysate from cellulose which can then undergo more severe/targeted treatment.Get more info...Pretreatment Homepage

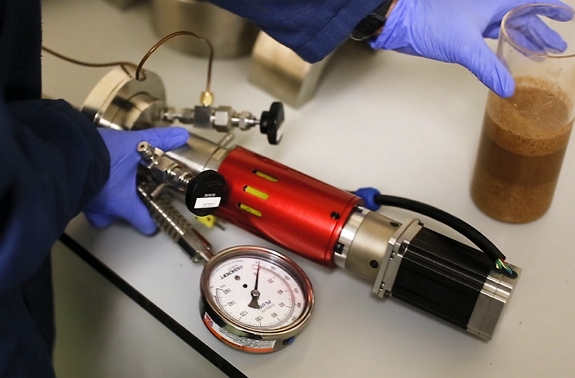

Mechanical Pretreatment of Biomass

It is generally the case that the smaller the particle size, the higher the efficiency of the process. However, excessive reduction in particle size may cause process issues (e.g. viscosity, high water holding, filter clogging etc.).

Depending on the pretreatment conditions, and on the particle-size reduction tools used in the process, the pretreatment process may also cause the biomass to shear and reduce the degree of polymerization, which in turn increases the available accessible area to chemicals, enzymes and microbes.

Other Types of Biomass Pretreament

Get more info...Steam Pretreatment

Get more info...Hydrothermal Pretreatment

Get more info...Acid Pretreatment

Get more info...Acid Pretreatment

Get more info...Organosolv Pretreatment

Get more info...Other Pretreatments

Get more info...Pretreatment Homepage

With regards to the pretreatment of biomass, the Celignis Bioprocess team members with the most experience in undertaking such projects are listed below. Feel free to contact them to discuss potential projects.

Lalitha Gottumukkala

Founder of Celignis Bioprocess, CIO of Celignis

PhD

Has a deep understanding of all biological and chemical aspects of bioproceses. Has developed Celignis into a renowned provider of bioprocess development services to a global network of clients.

Oscar Bedzo

Bioprocess Project Manager & Technoeconomic Analysis Lead

PhD

A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.