Analysis of Straw

Background on Straw

The yield of straw per unit mass of grain will vary according to the plant type and the local environment. However, the average yield of wheat straw is 1.3 to 1.4 kg per kg of grain.

Analysis of Straw at Celignis

Celignis Analytical can determine the following properties of Straw samples:

Lignocellulosic Properties of Straw

Cellulose Content of Straw

The specific cultivar of the species may also be important as the relative proportions of leaves and internodes may differ between varieties and different cultivars may also lose differing quantities of leaves in the harvesting process, due to variations in the brittleness of leaves.

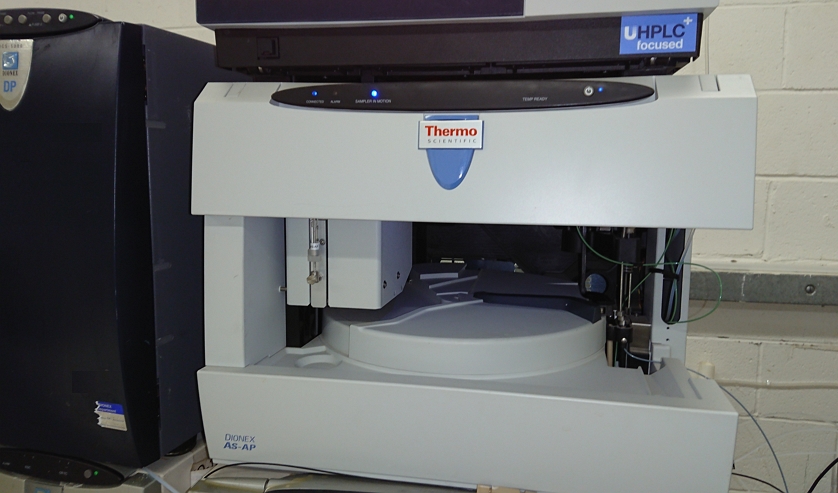

Celignis founder Daniel Hayes has extensive experience in the collection, preparation, and chemical/infrared analysis of straw samples. He has carried out research projects, funded by the Irish Environmental Protection Agency and the Irish Department of Agriculture, that involved the analysis of a variety of straw types.

Cellulose is the principal component in straw samples. The cellulose content can vary between different varieties of the same plant species. There is greater variability in cellulose content between straws from different plant species.

Click here to see the Celignis Analysis Packages that determine Cellulose Content

Request a QuoteCellulose Content

Hemicellulose Content of Straw

Click here to see the Celignis Analysis Packages that determine Hemicellulose Content

Request a QuoteHemicellulose Content

Lignin Content of Straw

Click here to see the Celignis Analysis Packages that determine Lignin Content

Request a QuoteLignin Content

Starch Content of Straw

Click here to see the Celignis Analysis Packages that determine Starch Content

Request a QuoteStarch Content

Uronic Acid Content of Straw

Click here to see the Celignis Analysis Packages that determine Uronic Acid Content

Request a QuoteUronic Acid Content

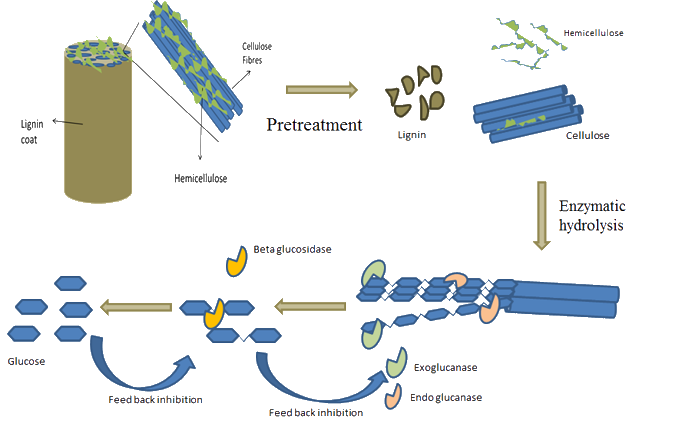

Enzymatic Hydrolysis of Straw

Click here to see the Celignis Analysis Packages that determine Enzymatic Hydrolysis

Request a QuoteEnzymatic Hydrolysis

Bioenergy Properties of Straw

Ash Content of Straw

Click here to see the Celignis Analysis Packages that determine Ash Content

Request a QuoteAsh Content

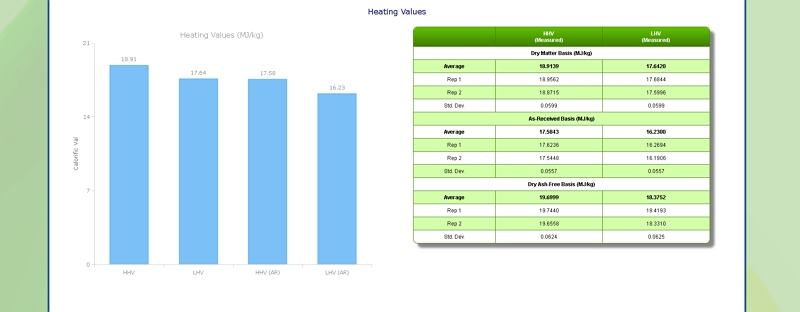

Heating (Calorific) Value of Straw

Click here to see the Celignis Analysis Packages that determine Heating (Calorific) Value

Request a QuoteHeating (Calorific) Value

Ash Melting Behaviour of Straw

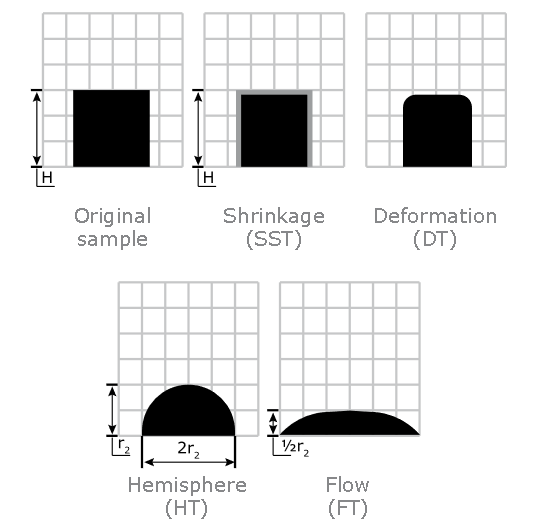

Ash Shrinkage Starting Temperature (SST) - This occurs when the area of the test piece of Straw ash falls below 95% of the original test piece area.

Ash Deformation Temperature (DT) - The temperature at which the first signs of rounding of the edges of the test piece occurs due to melting.

Ash Hemisphere Temperature (HT) - When the test piece of Straw ash forms a hemisphere (i.e. the height becomes equal to half the base diameter).

Ash Flow Temperature (FT) - The temperature at which the Straw ash is spread out over the supporting tile in a layer, the height of which is half of the test piece at the hemisphere temperature.

Click here to see the Celignis Analysis Packages that determine Ash Melting Behaviour

Request a QuoteAsh Melting Behaviour

Major and Minor Elements in Straw

We can also determine the levels of 13 different minor elements (such as arsenic, copper, and zinc) that may be present in Straw.

Click here to see the Celignis Analysis Packages that determine Major and Minor Elements

Request a QuoteMajor and Minor Elements

Analysis of Straw for Anaerobic Digestion

Biomethane potential (BMP) of Straw

Click here to see the Celignis Analysis Packages that determine BMP

Request a QuoteBMP

Physical Properties of Straw

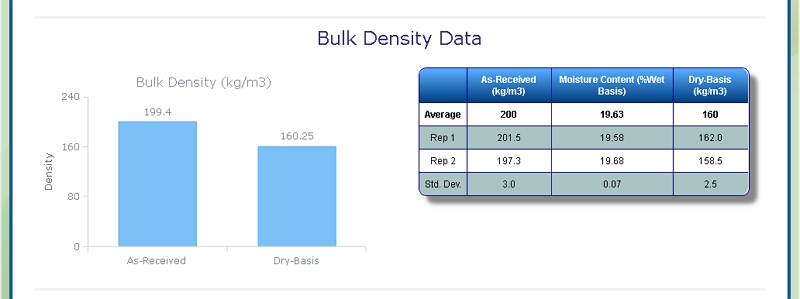

Bulk Density of Straw

At Celignis we can determine the bulk density of biomass samples, including Straw, according to ISO standard 17828 (2015). This method requires the biomass to be in an appropriate form (chips or powder) for density determination.

Click here to see the Celignis Analysis Packages that determine Bulk Density

Request a QuoteBulk Density

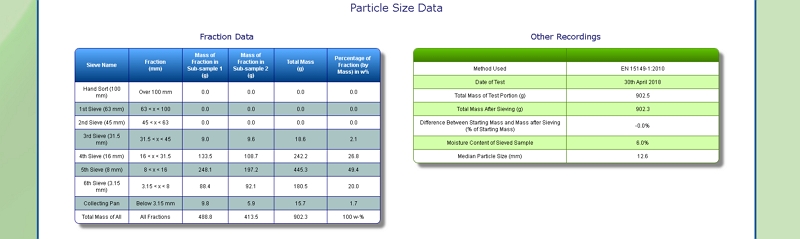

Particle Size of Straw

Click here to see the Celignis Analysis Packages that determine Particle Size

Request a QuoteParticle Size

Six conceptual process scenarios for the production of biobutanol from lignocellulosic biomass through acetone?butanol?ethanol (ABE) fermentation, using reported data on process performances, were developed with ASPEN Plus® V8.2 software. The six scenarios covered three fermentation strategies, i.e. batch separate hydrolysis and fermentation (SHF), continuous SHF, and batch simultaneous saccharification and fermentation (SSF) integrated with gas stripping (GS). The two downstream processing options considered were double?effect distillation (DD) and liquid?liquid extraction and distillation (LLE&D). It was found that the SSF?GS/DD scenario was the most energy efficient with a liquid fuel efficiency of 24% and an overall efficiency of 31%. This was also the scenario with the best economic outcome, with an internal rate of return (IRR) of 15% and net present value (NPV) of US$387 million. The SSF?GS/DD scenario was compared to a similar molasses process, based on the product flow rates, and it was found that the molasses process was more energy efficient with a gross energy value (GEV) of 23?MJ?kg1 butanol compared to ?117?MJ?kg1 butanol for the lignocellulosic process. In addition, the molasses?based process was more profitable with an IRR of 36% compared to 21%. However, the energy requirements for the molasses process were supplied from fossil fuels, whereas for the lignocellulose processes a portion of the feedstock was diverted to provide process energy. Improved environmental performance is therefore associated with the lignocellulosic process. | |

Next-generation biofuels from renewable sources have gained interest among research investigators, industrialists, and governments due to major concerns on the volatility of oil prices, climate change, and depletion of oil reserves. Biobutanol has drawn signicant attention as an alternative transportation fuel due to its superior fuel properties over ethanol. e advantages of butanol are its high energy content, better blending with gasoline, less hydroscopic nature, lower volatility, direct use in convention engines, low corrosiveness, etc. Butanol production through (acetone, butanol, and ethanol) ABE fermentation is a well-established process, but it has several drawbacks like feedstock cost, strain degeneration, product toxicity, and low product concentrations. Lignocellulosic biomass is considered as the most abundant, renewable, low-cost feedstock for biofuels. Production of butanol from lignocellulosic biomass is more complicated due to the recalcitrance of feedstock and inhibitors generated during the pretreatment and hydrolysis process. Advanced fermentation and product recovery techniques are being researched to make biobutanol industrially viable. | |

Clostridium sporogenes BE01, a non-acetone forming butanol producer, can produce hydrogen and volatile fatty acids (VFAs) during butanol fermentation from rice straw hydrolysate. Bio-electrochemical analysis revealed the changes that occurred in the redox microenvironment and electron transport mediators during fermentation at different pH and CaCO3 concentrations. CaCO3 played a very important role in enhancing the production of hydrogen, volatile fatty acids and solvents by stimulating the changes in the electron transport system. The electron transport system mediated by NAD/NADH, flavins, Fe–S clusters, protein bound FAD, and cytochrome complex in C. sporogenes BE01 was analysed by cyclic voltammetry (CV). Electrokinetic analysis revealed that the favorability for redox reactions increased with an increase in pH, and the polarization resistance reduced significantly with CaCO3 supplementation. | |

Growth inhibition kinetics of a novel non-acetone forming butanol producer, Clostridium sporogenes BE01, was studied under varying concentrations of acetic and formic acids in rice straw hydrolysate medium. Both the organic acids were considered as inhibitors as they could inhibit the growth of the bacterium, and the inhibition constants were determined to be 1.6 and 0.76 g/L, respectively, for acetic acid and formic acid. Amberlite resins—XAD 4, XAD 7, XAD 16, and an anion exchange resin—Seralite 400 were tested for the efficient removal of these acidic inhibitors along with minimal adsorption of sugars and essential minerals present in the hydrolysate. Seralite 400 was an efficient adsorbent of acids, with minimal affinity towards minerals and sugars. Butanol production was evaluated to emphasize the effect of minerals loss and acids removal by the resins during detoxification. | |

Biobutanol from lignocellulosic biomass has gained much attention due to several advantages over bioethanol. Though microbial production of butanol through ABE fermentation is an established technology, the use of lignocellulosic biomass as feedstock presents several challenges. In the present study, biobutanol production from enzymatic hydrolysate of acid pretreated rice straw was evaluated using Clostridium sporogenes BE01. This strain gave a butanol yield of 3.43 g/l and a total solvent yield of 5.32 g/l in rice straw hydrolysate supplemented with calcium carbonate and yeast extract. Hydrolysate was analyzed for the level of inhibitors such as acetic acid, formic acid and furfurals which affect the growth of the organism and in turn ABE fermentation. Methods for preconditioning the hydrolysate to remove toxic end products were done so as to improve the fermentation efficiency. Conditions of ABE fermentation were fine tuned resulting in an enhanced biobutanol reaching 5.52 g/l. | |

Biobutanol from lignocellulosic biomass has gained much attention due to several advantages over bioethanol. Though microbial production of butanol through ABE fermentation is an established technology, the use of lignocellulosic biomass as feedstock presents several challenges. In the present study, biobutanol production from enzymatic hydrolysate of acid pretreated rice straw was evaluated using Clostridium sporogenes BE01. This strain gave a butanol yield of 3.43 g/l and a total solvent yield of 5.32 g/l in rice straw hydrolysate supplemented with calcium carbonate and yeast extract. Hydrolysate was analyzed for the level of inhibitors such as acetic acid, formic acid and furfurals which affect the growth of the organism and in turn ABE fermentation. Methods for preconditioning the hydrolysate to remove toxic end products were done so as to improve the fermentation efficiency. Conditions of ABE fermentation were fine tuned resulting in an enhanced biobutanol reaching 5.52 g/l. | |

This document is the result of the evaluation of biomass feedstocks, from Europe and Latin America, that took place as part of the DIBANET project. That project is co-financed from the 7 th Framework Programme for Research and Technological Demonstration of the European Union. (Title: Enhancing international cooperation between the EU and Latin America in the field of biofuels; Grant Agreement No: 227248-2).

| |||

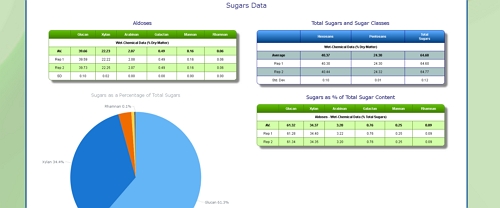

The processing of lignocellulosic materials in modern biorefineries will allow for the

production of transport fuels and platform chemicals that could replace petroleum-derived

products. However, there is a critical lack of relevant detailed compositional information

regarding feedstocks relevant to Ireland and Irish conditions. This research has involved the

collection, preparation, and the analysis, with a high level of precision and accuracy, of a

large number of biomass samples from the waste and agricultural sectors. Not all of the

waste materials analysed are considered suitable for biorefining; for example the total sugar

contents of spent mushroom composts are too low. However, the waste paper/cardboard

that is currently exported from Ireland has a chemical composition that could result in high

biorefinery yields and so could make a significant contribution to Ireland’s biofuel demands. | ||

Aspergillus niger NII-08121/MTCC 7956 exhibited differences in expression of ?-glucosidase (BGL) in response to carbon sources provided in the medium. Activity staining with methyl umbelliferyl ?-d-glucopyranoside (MUG) indicated that four different isoforms of BGL were expressed when A. niger was grown under submerged fermentation with either lactose or cellulose, whereas only two were expressed when wheat bran or rice straw was used as the carbon source. Among the four isoforms of BGL expressed during lactose supplementation, two were found to retain 92% and 82% activity respectively in presence of 250 mM glucose in the MUG assay. The major ?-glucosidase (BGL1) was purified to homogeneity by electro elution from a Native PAGE gel. The purified 120 kDa protein was active at 50 °C and was stable for 48 h without any loss of activity. The optimum pH and temperature were 4.8 and 70 °C respectively. | |

Rice straw is an attractive lignocellulosic material for bioethanol production since it is one of the most abundant renewable resources. It has several characteristics, such as high cellulose and hemicelluloses content that can be readily hydrolyzed into fermentable sugars. But there occur several challenges and limitations in the process of converting rice straw to ethanol. The presence of high ash and silica content in rice straw makes it an inferior feedstock for ethanol production. One of the major challenges in developing technology for bioethanol production from rice straw is selection of an appropriate pretreatment technique. The choice of pretreatment methods plays an important role to increase the efficiency of enzymatic saccharification thereby making the whole process economically viable. The present review discusses the available technologies for bioethanol production using rice straw. | |