Analysis of Pretreated Biomass

Background on Pretreated Biomass

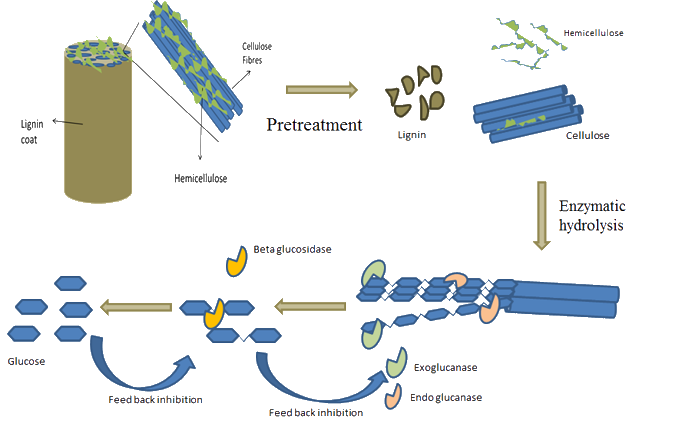

Types of pretreatment include: particle size reduction; steam explosion; ammonia fibre explosion; liquid hot water treatment; dilute acids; alkalis; wet oxidation; organosolv; formic acid; hydrogen peroxide; supercritical CO2; ionic liquids; ozonolysis; and biological pretreatments.

Our Recommendations for Evaluating Pre-Treatment Processes

We have a lot of experience in analysing many products (both liquid and solid) from biomass pre-treatment processes. These samples have covered a wide variety of starting feedstocks and pre-treatment processes and conditions. Below we recommend a set of Celignis analysis packages for getting the most detailed data about the whole conversion process:

(1) The Starting Feedstock

We recommend that analysis package P10 - Sugars, Lignin, Extractives, and Ash is used as this will fully remove the extractives prior to the hydrolysis stage meaning that you can be confident that the sugars reported in this package come from lignocellulose.

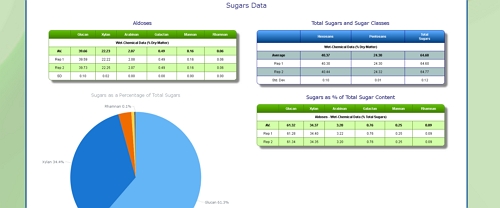

We would also recommend analysis package P12 - Sugars in Solvent Extract as this will report the amount of water-soluble carbohydrates in the sample. It is likely that water-soluble carbohydrates will be present in the liquid output of many pre-treatment processes and, if their concentrations are not known, it may be incorrectly inferred that such sugars present in the liquid must come from lignocellulose. However, if the water-soluble carbohydrate composition is known then these values can be substracted from the amounts of sugars in the pre-treatment liquid to determine the amount of true lignocellulosic sugars that are present.

Similarly, if you expect that there will be some starch in your sample then we also recommend that analysis package P14 - Starch Content is also undertaken as starch may also be removed and hydrolysed in many pre-treatment processes.

Additionally, if you are interested in the uronic acid composition of the biomass then we recommend analysis package P15 - Uronic Acids is also undertaken.

(2) The Liquid Product from Pre-treatment

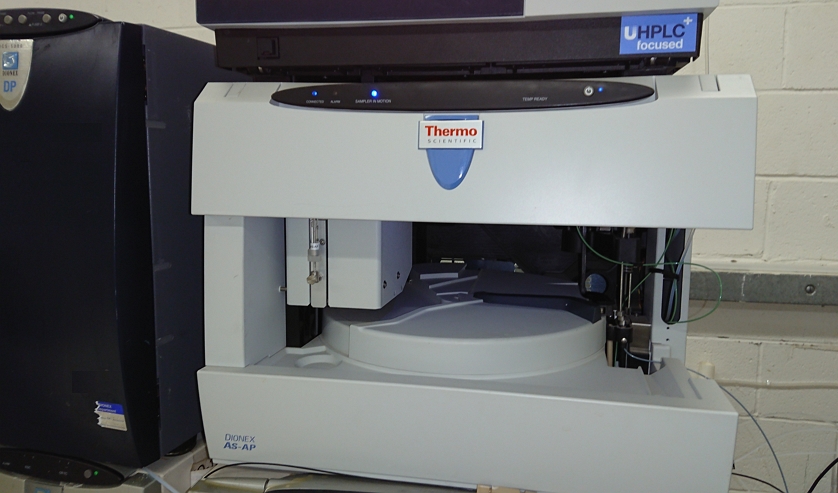

For the most detailed results, we would recommend that the liquid output is analysed using analysis packages P13 - Sugars and Oligosaccharides in Solution, P22 - Organic Acids and Furans, and P15 - Uronic Acids. However, if uronic acids are expected to be very low in your original biomass sample then that analysis package may not need to be undertaken.

(3) The Solid Residue from Pre-treatment

As it is likely that most of the extractives will have been removed in the pre-treatment, it may not be necessary to remove or characterise these. Instead, we recommend that analysis package P9 - Lignocelullosic Sugars and Lignin is undertaken to determine the lignocellulosic composition of the residue. We would also recommend that analysis package P3 - Ash Content is also undertaken to see whether the pre-treatment process significantly changes the ash content of the sample. Also, if the fate of the uronic acids is of interest then analysis package P15 - Uronic Acids could be undertaken.

Analysis of Pretreated Biomass at Celignis

Celignis Analytical can determine the following properties of Pretreated Biomass samples:

Lignocellulosic Properties of Pretreated Biomass

Cellulose Content of Pretreated Biomass

Click here to see the Celignis Analysis Packages that determine Cellulose Content

Request a QuoteCellulose Content

Hemicellulose Content of Pretreated Biomass

Click here to see the Celignis Analysis Packages that determine Hemicellulose Content

Request a QuoteHemicellulose Content

Lignin Content of Pretreated Biomass

Click here to see the Celignis Analysis Packages that determine Lignin Content

Request a QuoteLignin Content

Starch Content of Pretreated Biomass

Click here to see the Celignis Analysis Packages that determine Starch Content

Request a QuoteStarch Content

Uronic Acid Content of Pretreated Biomass

Click here to see the Celignis Analysis Packages that determine Uronic Acid Content

Request a QuoteUronic Acid Content

Enzymatic Hydrolysis of Pretreated Biomass

Click here to see the Celignis Analysis Packages that determine Enzymatic Hydrolysis

Request a QuoteEnzymatic Hydrolysis

Bioenergy Properties of Pretreated Biomass

Ash Content of Pretreated Biomass

Click here to see the Celignis Analysis Packages that determine Ash Content

Request a QuoteAsh Content

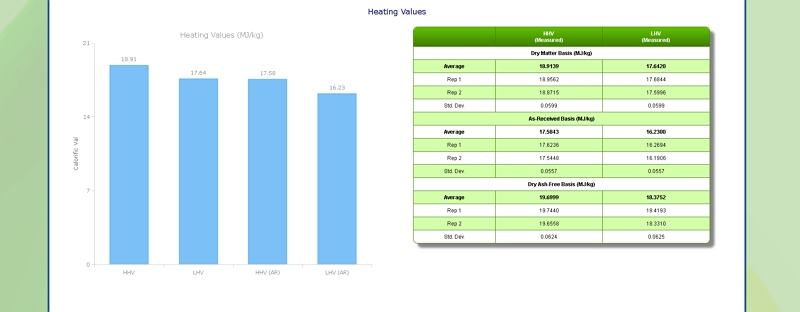

Heating (Calorific) Value of Pretreated Biomass

Click here to see the Celignis Analysis Packages that determine Heating (Calorific) Value

Request a QuoteHeating (Calorific) Value

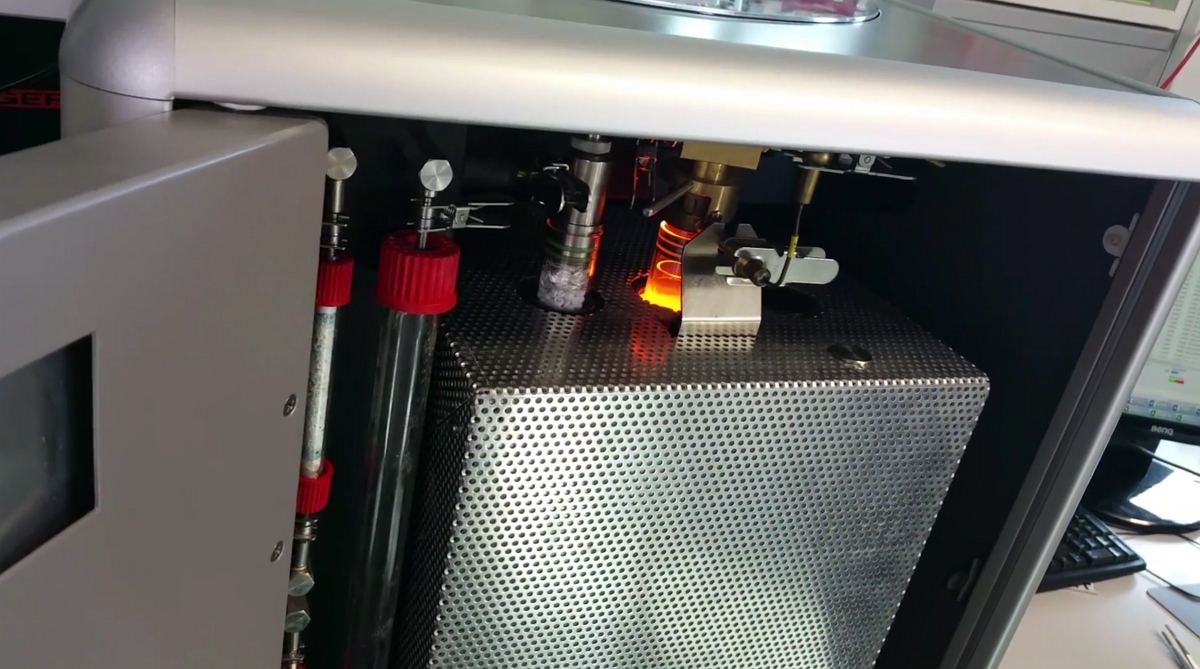

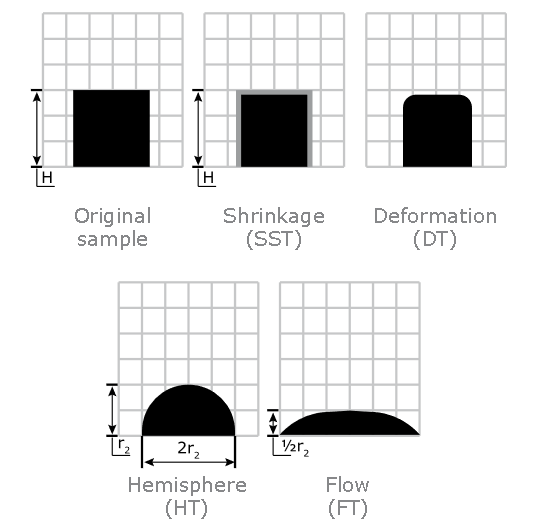

Ash Melting Behaviour of Pretreated Biomass

Ash Shrinkage Starting Temperature (SST) - This occurs when the area of the test piece of Pretreated Biomass ash falls below 95% of the original test piece area.

Ash Deformation Temperature (DT) - The temperature at which the first signs of rounding of the edges of the test piece occurs due to melting.

Ash Hemisphere Temperature (HT) - When the test piece of Pretreated Biomass ash forms a hemisphere (i.e. the height becomes equal to half the base diameter).

Ash Flow Temperature (FT) - The temperature at which the Pretreated Biomass ash is spread out over the supporting tile in a layer, the height of which is half of the test piece at the hemisphere temperature.

Click here to see the Celignis Analysis Packages that determine Ash Melting Behaviour

Request a QuoteAsh Melting Behaviour

Major and Minor Elements in Pretreated Biomass

We can also determine the levels of 13 different minor elements (such as arsenic, copper, and zinc) that may be present in Pretreated Biomass.

Click here to see the Celignis Analysis Packages that determine Major and Minor Elements

Request a QuoteMajor and Minor Elements

Analysis of Pretreated Biomass for Anaerobic Digestion

Biomethane potential (BMP) of Pretreated Biomass

However, the increase in BMP often varies greatly according to the conditions and type of pre-treatment employed. For that reason we recommend that the biochemical methane potential test is undertaken in order to evaluate the effectiveness of any given pre-treatment process regarding improving potential biogas yields in anaerobic digestion.

Click here to see the Celignis Analysis Packages that determine BMP

Request a QuoteBMP

Physical Properties of Pretreated Biomass

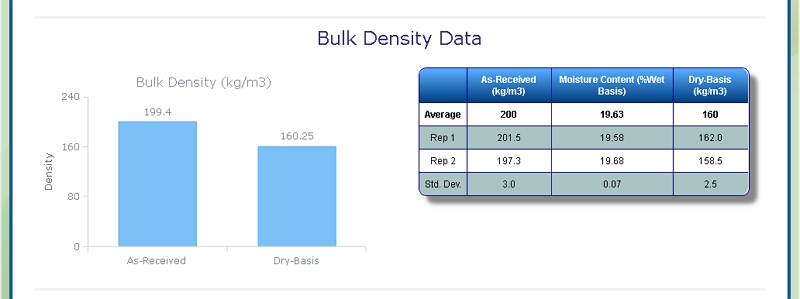

Bulk Density of Pretreated Biomass

At Celignis we can determine the bulk density of biomass samples, including Pretreated Biomass, according to ISO standard 17828 (2015). This method requires the biomass to be in an appropriate form (chips or powder) for density determination.

Click here to see the Celignis Analysis Packages that determine Bulk Density

Request a QuoteBulk Density

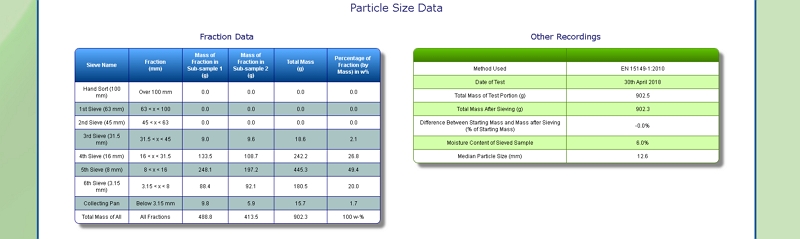

Particle Size of Pretreated Biomass

However, the increase in BMP often varies greatly according to the conditions and type of pre-treatment employed. For that reason we recommend that the biochemical methane potential test is undertaken in order to evaluate the effectiveness of any given pre-treatment process regarding improving potential biogas yields in anaerobic digestion.

Click here to see the Celignis Analysis Packages that determine Particle Size

Request a QuoteParticle Size