Production of Xylitol from Biomass

Biobased Chemicals - Background

Rationale for Biobased Chemicals Production

The production of chemicals from biomass, also known as bio-based chemicals, plays a critical role in creating a sustainable and environmentally friendly future, particularly as the world strives to reduce dependence on fossil fuels. Some of the advantages of biobased chemicals are listed below:- Climate Change Mitigation - Unlike fossil fuels, bio-based chemicals are made from plant materials that recently absorbed carbon dioxide from the atmosphere.

- Security of Supply - Fossil fuel supply often is reliant on geopolitically unstable regions. Developing domestic sources of biomass and the infrastructure to convert such feedstocks to chemicals, can help improve national chemicals security.

- Sustainable Development - Biomass can often be produced and processed locally, promoting rural development and creating jobs in agriculture, industry, and research.

- Waste Management - Biomass for bio-based chemicals can come from waste residues from agriculture, forestry, or even municipal waste. Using these waste streams for biobased chemicals can help solve waste disposal problems.

- Biodegradability - Many bio-based chemicals and the products made from them are biodegradable, avoiding environmental pollution associated with many fossil-derived resources.

- Resource Efficiency - The use of biomass as a raw material can contribute to a more circular economy, where waste from one process becomes the feedstock for another. This approach increases resource efficiency and reduces environmental impact compared to linear models of production.

Approaches for the Production of Biobased Chemicals

There are two main ways in which biobased chemicals can be obtained from biomass feedstocks:- Direct Extraction from Biomass - In this approach the target chemicals already exist within the feedstock. Hence, the focus of the bioprocess is on the extraction of the target chemical and then on subsequent separation and purification steps. CBD (cannabidiol), an alkaloid obtained from extracts of the hemp (cannabis) plant, is one example, among thousands, of a biobased chemical obtained this way.

- Production from Biomass or Biomass-Derived Compounds - Here the biobased chemical does not exist natively in the feedstock but is produced from it. This conversion can involve chemical, thermal, catalytic, and biological approaches or a combination of these. It is usually the case that the key stage of the bioprocess, where the biobased chemical is produced, works on a fraction, or derivative, of the original biomass feedstock. For example, ethanol can be produced via fermentation of the monomeric sugars obtained when the lignocellulosic polysaccharides (cellulose and/or hemicellulose) are hydrolysed. Alternatively, ethanol can also be produced via catalytic reforming of the syngas produced in the gasification of biomass.

How Celignis Can Help

At Celignis our multidisciplinary team has strong understanding of: biomass chemistry, bioprocessing technologies, and the mechanisms and challenges involved in producing a wide variety of biobased chemicals. We are ready to work with you on developing a suitable bioprocess to either obtain your targeted biobased chemical from biomass or to obtain the most appropriate biobased chemicals from a given feedstock.

Xylitol Chemistry and Applications

Xylitol is a five-carbon sugar alcohol, chemically classified as a polyol. It is a white crystalline solid that is soluble in water, with a sweet taste similar to that of sucrose. It has the chemical formula C5H12O5.As a sugar alcohol, xylitol is neither a sugar nor an alcohol in the traditional sense, but shares some properties with both. It has the same sweetness as sucrose, but with approximately 40% fewer calories, which makes it a popular choice as a sugar substitute in many "sugar-free" and "low-calorie" products.

Xylitol has many important applications, a few of these are listed below:

- Food Industry - Xylitol is used extensively in the food industry as a sugar substitute. It is used in a variety of products including chewing gum, candy, baked goods, and other food items, particularly those marketed as "sugar-free" or "low-calorie."

- Dental Health - One of the unique benefits of xylitol is its ability to help prevent tooth decay. Unlike sugars, which can contribute to tooth decay, xylitol is not fermented by oral bacteria, and thus does not produce the acids that lead to tooth decay. It can even inhibit the growth of certain bacteria, such as Streptococcus mutans, which are known to cause tooth decay.

- Pharmaceuticals - Xylitol is used in pharmaceuticals and personal care products like toothpaste, mouthwash, and certain over-the-counter drugs due to its antibacterial properties and its ability to increase the bioavailability of certain drugs.

- Nutraceuticals - Due to its low calorie content and low glycemic index (it is metabolized independently of insulin), xylitol is popular in nutraceuticals and food products designed for diabetics and those on calorie-restricted diets.

History of Xylitol Production

The history of xylitol production goes back to the late 19th and early 20th centuries. Xylitol was first discovered and isolated by German and French chemists in the late 19th century, though it remained a relatively obscure compound for several decades due to the lack of efficient production methods.The interest in xylitol production increased during World War II due to sugar shortages. Finland, a country rich in birch trees, began to investigate the production of xylitol from the xylan-rich hemicellulose fraction of birch wood as a substitute for sugar. This marked the beginning of large-scale xylitol production.

Early xylitol production processes were based on the acid hydrolysis of hardwood xylan to yield xylose, which was then reduced to xylitol by catalytic hydrogenation. However, these early processes were energy-intensive and had relatively low yields.

In the second half of the 20th century, more efficient processes were developed. A significant advance was the development of the so-called "sugar platform" approach, which involves the enzymatic hydrolysis of hemicellulose to produce xylose, followed by microbial fermentation to convert the xylose into xylitol. This process, although more efficient than acid hydrolysis, is still challenging due to the relatively low yields and the need for extensive purification of the final product.

Most commercial xylitol is still produced by the catalytic hydrogenation of xylose derived from hardwoods or corncobs. These processes can be considered "biobased" in the sense that they start from renewable feedstocks, but they still rely on industrial chemical processes for the actual production of xylitol.

There's currently interest in producing xylitol via microbial fermentation directly from lignocellulosic biomass. However, this approach presents its own challenges, including the need to develop more efficient microbial strains and processes.

Biomass Hydrolysis to Xylose

Xylitol is currently mostly produced from the pentose sugars (primarily xylose) present in the hemicellulose polysaccharides of lignocellulosic feedstocks.The first step is to hydrolyse hemicellulose in order to obtain these monomers. This hydrolysis can involve enzymes and be undertaken alongside the hydrolysis of cellulose. However, depending on the pretreatment method used, hemicellulose may end up in the liquid output stream of that pretreatment. For example, hemicelluloses tend to be well hydrolysed in dilute-acid pretreatments and, depending on the process conditions, in hydrothermal (Liquid Hot Water) pretreatments. Hence, the production of xylitol can be a means of valorising the pretreatment liquid sidestreams in bioprocesses involving the pretreatment of biomass for subsequent enzymatic hydrolysis of cellulose.

Catalytic Production of Xylitol from Xylose

The chemical approach to xylitol production from xylose generally involves a process known as catalytic hydrogenation. The main steps and parameters of the process are described below:- Feeding the Reactants: Xylose and hydrogen are fed into a reaction vessel. The xylose can be in a pure form or as part of a solution, whilst the hydrogen is typically provided as a gas.

- Catalysis: The reaction is facilitated by a catalyst, typically a metal such as nickel, ruthenium, or palladium supported on a carrier like silica or activated carbon. The catalyst accelerates the hydrogenation process, helping the hydrogen atoms to be added across the carbonyl group in xylose, reducing it to the alcohol group in xylitol.

- Reaction conditions: The reaction is typically carried out at elevated temperatures (100-160 °C) and pressures (20-50 bar), although this can vary depending on the specific process and catalyst used. The pH of the reaction is also controlled, as it can affect the selectivity of the hydrogenation reaction towards xylitol.

- Product Separation: After the reaction, the product mixture typically needs to be separated and purified. This can involve steps such as filtration to remove the catalyst, evaporation to concentrate the xylitol, and crystallization to obtain pure xylitol.

Xylitol via Fermentation of Xylose

An alternative to the chemical approach for xylitol production is to use microorganisms, such as yeast or bacteria, that have the ability to convert xylose into xylitol. The process is essentially a specialized form of fermentation.Several species of yeasts and bacteria have been identified as potential candidates for this fermentation, including species of Candida, Pichia, and Debaryomyces. Some microorganisms naturally produce xylitol, while others have been genetically modified to enhance their xylitol production capabilities. Some yeast strains have been shown to tolerate high sugar concentrations and produce high xylitol yields.

During the fermentation process the microorganisms metabolize xylose primarily through the pentose phosphate pathway. In this pathway, xylose is first reduced to xylitol by xylose reductase, an enzyme that the microorganisms produce. This step requires the co-factor NADPH. Xylitol is then oxidized to xylulose by xylitol dehydrogenase using NAD+. However, the latter step is typically slower and less efficient, leading to an accumulation of xylitol, which is then excreted by the cells.

Some important parameters for the fermentation are described below:

- Fermentation Time - Fermentation time can affect xylitol yield. In batch fermentation, the process might take several days. In continuous or fed-batch fermentation, it is controlled by feeding rates and other parameters.

- Fermentation Mode - The mode of fermentation can influence xylitol production. In batch fermentation, all nutrients are added at the beginning, while in fed-batch or continuous fermentation, nutrients are added over time. Fed-batch or continuous fermentation can potentially give higher xylitol yields, as they allow better control over the fermentation conditions.

- Presence of Fermentation Inhibitors - Depending on the source of xylose (e.g the hydrolysis or pretreatment method employed), the feed may contain toxic compounds that inhibit the growth of the microorganisms or the fermentation process. These toxins need to be removed or neutralized before or during fermentation. Alternatively, microorganisms that are less sensitive to these inhibitors should be used.

Chemical Vs Biological Approach

Advantages of the chemical method over the biological method:- High yield - The chemical method generally provides a high yield, often greater than 90%.

- Robust and Predictable - The process is less susceptible to contamination compared to biological methods and it has less variability, leading to more predictable outputs.

- Scalability - This method is often used in commercial production as it can be effectively scaled up for industrial application.

- High Energy Consumption - The process requires high temperatures and pressures, leading to substantial energy consumption.

- Use of Hazardous Materials - The use of potentially dangerous substances like hydrogen gas and catalysts like nickel, ruthenium, or palladium can pose safety and environmental risks.

- Catalyst Deactivation - he catalyst may need to be frequently replaced due to deactivation over time, adding to the process costs.

- Lower Energy Requirements - The process operates at ambient or near-ambient conditions, resulting in less energy consumption.

- Environmentally Friendly - It does not require the use of harsh chemicals, and does not generate hazardous waste.

- Flexibility - There's potential for further transformation of xylose into other value-added products due to the metabolic versatility of microorganisms.

- Lower Yield - The yield of xylitol is typically lower than the chemical method, though research is ongoing to improve this.

- Contamination Risks - The fermentation process is susceptible to contamination, which could disrupt xylitol production.

- Feedstock Issues - The hydrolysates used as feedstock can contain inhibitors that negatively impact microbial growth and fermentation, necessitating additional detoxification steps.

- Separation and Purification - The fermentation broth contains various by-products, necessitating extensive purification steps to obtain pure xylitol.

Xylitol from Hexose Sugars

While xylitol is typically derived from the pentose sugar xylose, it is also possible to produce xylitol from hexose sugars like glucose, derived from the cellulose fraction of lignocellulosic biomass. This involves the use of certain microorganisms that can convert hexose sugars into xylitol. It is worth noting, however, that this process is less straightforward and efficient than the direct reduction of xylose to xylitol, and is still a subject of ongoing research.One approach for converting hexose sugars into xylitol involves genetically engineered microorganisms. Through metabolic engineering, the natural metabolic pathways in these microorganisms can be modified to divert glucose metabolism towards the production of xylitol. A commonly used microorganism for this purpose is Saccharomyces cerevisiae (yeast), which naturally metabolizes glucose through glycolysis. By introducing the genes for xylose reductase and xylitol dehydrogenase (enzymes that convert xylose into xylitol), and modifying other metabolic pathways, the yeast can be engineered to convert glucose into xylitol.

However, it is important to highlight that this is a challenging process. Glucose naturally tends to be metabolized to ethanol in yeast, and redirecting this metabolism towards xylitol production requires significant metabolic engineering. Furthermore, the yield of xylitol from glucose is typically lower than that from xylose, as the conversion involves more steps and is less direct. Therefore, while it is technically possible to produce xylitol from hexose sugars, it is typically more practical and efficient to use pentose sugars like xylose as the starting material and then to use the biomass-derived hexose sugars as substrates for the production of other biobased chemicals (e.g. bioethanol, biobutanol etc.).

Higher-Value Chemicals from Xylitol

Xylitol can be also be upgraded to other higher value chemicals. Below are listed a few examples of chemicals that can be derived from xylitol:- Furans - Xylitol can be converted into furanic compounds, such as furfural and hydroxymethylfurfural (HMF), through dehydration reactions. Furans are versatile platform chemicals that can be further transformed into a variety of high-value chemicals and materials.

- Xylaric acid - Xylitol can be oxidized to form xylaric acid, a compound with potential applications in biodegradable polymers and as a building block for chemical synthesis.

- Xylonates - Oxidation of xylitol can also lead to the production of xylonates, such as xylonic acid, which has potential uses in food, pharmaceuticals, and chemical industries.

- Polyols - Xylitol is itself a polyol, but it can also be chemically modified to produce other polyols with different properties, which can be used in various applications like pharmaceuticals, food products, and polymer synthesis.

- Biofuels - Xylitol can be used as a starting material for the production of biofuels. For example, it can be converted into butanol through a series of fermentation and catalytic steps.

1. Understanding Your Requirements

Prior to undertaking bioprocess projects we learn from our clients what their targets are from the process as well as whether there are any restrictions or requirements that may need to form the boundaries of the work that we undertake. These help to guide us to then prepare a potential bioprocess development project.

For example, in the context of xylitol production, the primary focus of one client may be on the production of xylitol in the highest possible yields from a particular feedstock whereas, for another client, the primary focus may be on cellulose valorisation, with the production of xylitol from the xylose fraction being a lower priority. These different preferences are likely to influence our choices of pretreatment technology, hydrolysis and fermentation approaches, and process conditions.

Additionally, based on their existing infrastructure or other factors, the client may express a preference for a certain route (chemical or biological) for the production of xylitol which will affect our choices in subsequent stages of the project.

2. Detailed Feedstock Analysis

In cases where you have already selected a feedstock for the bioprocess, we would then undertake a detailed compositional analysis (P10 or, ideally, P19) of representative samples of that feedstock.

In cases where the feedstock has not yet been selected we can review your list of candidate feedstocks, selecting top candidates based on our prior experience in their analysis and bioprocessing. If you do not have a list of candidate feedstocks then we can provide one, based on your location and the requirements outlined in Stage 1. We would then analyse in detail these priority feedstocks and come to a decision, based on the compositional data and other relevant factors (e.g. price, supply, consistency etc.) on a selected feedstock for the project.

At this point of the project, the Celignis Bioprocess team typically meet to discuss and prepare a project proposal for the development of a bioprocess for xylitol production from this feedstock. After this proposal is reviewed by the client, and revised if needed, we are then ready to start work on the next stages.

3. Hydrolysis to Xylose (Lab-Scale)

We will undertake a number of hydrolysis experiments, focused on the extraction of xylose from the feedstock. These are often termed pretreatment experiments, when considering lignocellulosic biomass as a whole since methods for hemicellulose hydrolysis may not hydrolyse cellulose. Alternatively, depending on the we workplan established in Stage 2, we can work on the more extensive hydrolysis of biomass, releasing sugars from both hemicellulose and cellulose. However this approach would itself require some form of pretreatment in order to allow for the enzymes to effectively hydrolyse the biomass.

Our hydrolysis experiments will follow a scientifically-based Design of Experiments (DoE) protocol where the criteria and boundaries for this DoE are formulated in close collaboration with our clients, considering the chemistry of the feedstock(s) and our understandings of the mechanisms of biomass hydrolysis conversion.

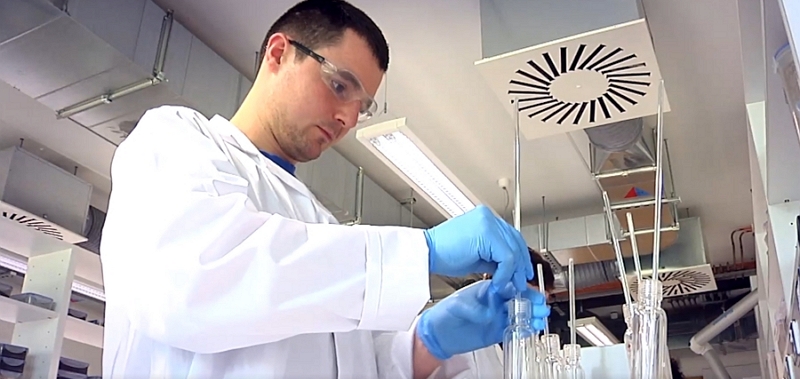

We usually recommend that these initial optimisation experiments are undertaken at the lab-scale (around TRL3) in order to reduce costs and the length of the project. For each experiment we analyse the solid and liquid outputs of the process, leading to a detailed data-set where effects of process conditions on the yield and composition of the various streams can be explored and mapped.

We can also undertake a second iteration of lab-scale experiments in order to fine-tune the conditions based on the knowledge gained in the initial experiments.

4. Xylitol Production

At the project proposal stage we will have decided with regards to whether the chemical or biological route would be applied for the production of xylitol from xylose.

In either case, our experimental work would follow a Design of Experiments (DoE) protocol, as outlined in Stage 3, in order to optimise the various process parameters for xylitol production. As before, these optimisation experiments are recommended to be undertaken at the lab-scale in order to accelerate the outputs and reduce project costs.

This stage can follow the hydrolysis optimisation activities, however in some cases it is recommended that these two stages overlap due to the interdependencies between them with regards to the ultimate yields and efficiencies of xylitol production.

5. Xylitol Recovery

Based on the outputs of the prior lab-scale Stages we can optimise the methods employed for separating and purifying the xylitol from the process. We can also potentially look at the recovery of other compounds from the liquid.

It is possible for this Stage to run alongside Stage 4.

6. Valorisation of Remaining Biomass

Depending on the pretreatment, hydrolysis, and fermentation processess employed in the project, we can look at valorising those biomass components that are not used for xylitol production. For example, we can assess the cellulose residue as a feedstock for enzymatic hydrolysis and for the subsequent fermentation of the liberated glucose to bioethanol.

7. Validation at Higher TRLs

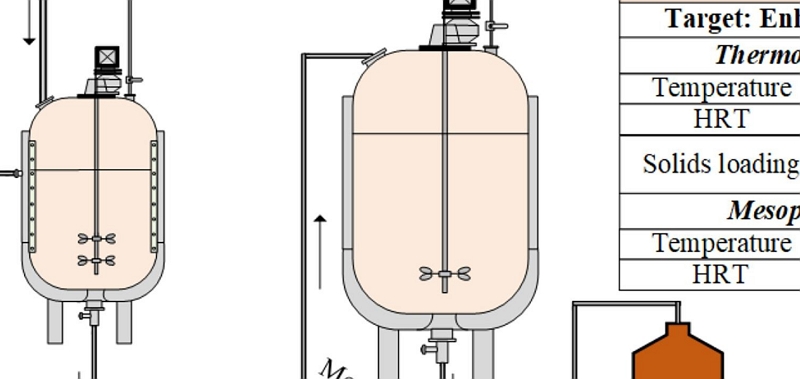

Once we have concluded our optimisation of the xylitol bioprocess conditions at the lab-scale we can then test those conditions at higher technology readiness levels (TRLs). The scales at which we can operate are dependent on the type of technology employed, but can reach up to 100 litres.

We have all of the necessary downstream equipment to efficiently handle the solid and liquid streams arising from these scaled-up activities.

If we find that there are differences between the yield and compositions of the different streams, compared with our lab-scale experiments, then we can explore the potential reasons for these and work on final tweaks to optimise the bioprocess for higher TRLs.

8. Technoeconomic Analysis (TEA)

The Celignis team, including Oscar our chief TEA expert, can undertake a detailed technoeconomic analysis of the developed process. We apply accurate and realistic costing models to determine the CAPEX and OPEX of simulated and pilot scale processes which are then used to determine key economic indicators such as IRR, NPV and payback periods.

Within these TEAs we can undertake sensitivity analyses to assess the effect of variable costs and revenues on the commercial viability of the xylitol production process.

Our preferred approach is to include TEA studies at each stage of the development of the bioprocess, so that the process can be optimised in a commercially-relevant way, followed by a more detailed TEA after the process has been optimised and tested at higher TRL levels.

Click here to read more about the technoeconomic analysis (TEA) services offered by Celignis.

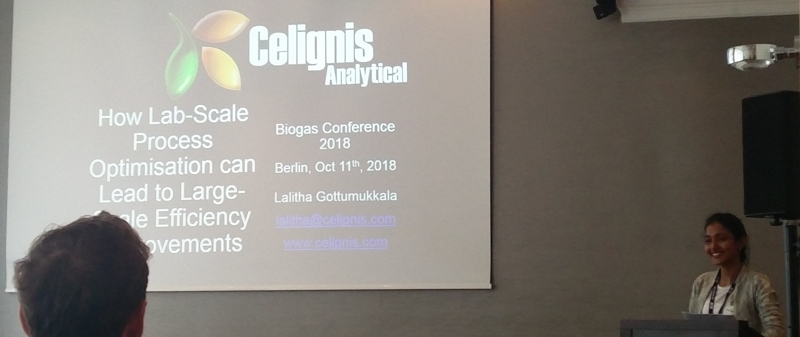

Lalitha Gottumukkala

Founder of Celignis Bioprocess, CIO of Celignis

PhD

<p style="text-align: left;">Has a deep understanding of all biological and chemical aspects of bioproceses. Has developed Celignis into a renowned provider of bioprocess development services to a global network of clients.</p>

Oscar Bedzo

Bioprocess Project Manager & Technoeconomic Analysis Lead

PhD

<p style="text-align: left;">A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.</p>

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

<p style="text-align: left;">Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.</p>

Bioethanol

Biobutanol

Hydrothermal carbonization (HTC) research has mainly focused on primary char production, with limited attention to secondary char, which is formed through polymerization and condensation of dissolved organic compounds in the liquid phase. This research aims to address this gap via an experimental investigation of the impact of stirring on the mass and carbon balance of HTC reaction products, surface functional groups, and surface morphology of secondary char, using fructose as a model compound. A 3D hydrodynamic simulation model was developed for a two-liter HTC stirred reactor. The experimental results indicated that stirring did not significantly influence the pH, mass, carbon balance, and surface functional groups of secondary char produced under the range of experimental conditions (180 C, 10% biomass to water (B/W) ratio, and a residence time of 0-120 min) studied. Nonetheless, it was observed that a stirring rate of 200 rpm influenced the morphology and shape of the secondary char microspheres, leading to a significant increase in their size i.e., from 1-2 um in unstirred conditions compared with 70 um at a stirring rate of 200 rpm. This increase in size was attributed to the aggregation of microspheres into irregular aggregates at stirring rates > 65 rpm and residence times > 1 h. The hydrodynamic model revealed that high turbulence of Re > 104 and velocities > 0.17 m s-1 correlated with regions of secondary char formation, emphasizing their role in particle aggregation. Particle aggregation is significant above a stirring rate of 65 rpm, which corresponds to the onset of turbulent flow in the reactor. Finally, a mechanism is proposed, based on reactor hydrodynamics under stirred conditions, that explains secondary char deposition on the reactor walls and stirrer. | |

A dried dairy processing sludge (sludge from wastewater treatment of an effluent from a milk processing plant) was pyrolysed in a single-particle reactor at different temperatures from 400 C to 900 C. NH3 and HCN were measured online and offline by means of FTIR as well as by cumulative sampling in impinger bottles (in 0.05 M H2SO4 and 1 M NaOH, respectively) and analysed by photometric method. NO and NO2 were measured online using a nitric oxide analyser while N2O was measured by FTIR. Nitrogen (N) in the sludge and in the remaining char, char-N, was determined. Moreover, tar content in pyrolysis gas was measured and tar-N was determined. The results with respect to N mass balance closure are discussed. The different measurements techniques are compared. For pyrolysis at 520 and 700 nitrogen in the gas phase was mainly contained as N2 (36 % and 40 % respectively), followed by NH3 (15 % and 18 %), tar-N (10 % and 9 %), HCN (1 % and 3 %), NO (1 %) and NO2 (0.2 %). The dairy processing sludge has very specific properties with organic-N present predominantly as proteins and a high content of inherent Ca. These characteristics affected the distribution of N. The amount of char-N was higher while the amount of tar-N lower than for sewage sludge from literature, at comparable pyrolysis temperature. | |

Dairy processing sludge (DPS) is a byproduct generated in wastewater treatment plants located in dairy (milk) processing companies (waste activated sludge). DPS presents challenges in terms of its management (as biosolids) due to its high moisture content, prolonged storage required, uncontrolled nutrient loss and accumulation of certain substances in soil in the proximity of dairy companies. This study investigates the potential of hydrothermal carbonization (HTC) for recovery of nutrients in the form of solid hydrochar (biochar) produced from DPS originating from four different dairy processing companies. The HTC tests were carried out at 160 C, 180 C, 200 C and 220 C, and a residence time of 1h. The elemental properties of hydrochars (biochars), the content of primary and secondary nutrients, as well as contaminants were examined. The transformation of phosphorus in DPS during HTC was investigated. The fraction of plant available phosphorus was determined. The properties of hydrochar (biochar) were compared against the European Union Fertilizing Products Regulation. The findings of this study demonstrate that the content of nutrient in hydrochars (biochars) meet the requirements for organo-mineral fertilizer with nitrogen and phosphorus as the declared nutrients (13.9-26.7%). Further research on plant growth and field tests are needed to fully assess the agronomic potential of HTC hydrochar (biochar). | |

Disposal of waste-activated sludge [dairy processing sludge, (DPS)] from wastewater treatment plants located in milk processing companies is an increasing concern. DPS is usually applied to farmlands in the vicinity of the dairy companies. This practice is becoming unsustainable due to uncontrolled nutrient loss and potential soil contamination. We propose to recover nutrients in the form of biochar. This paper examines the properties of biochars obtained from slow pyrolysis of DPS. DPS samples were pyrolyzed at laboratory and pilot scale at 600 and 700 C. The elemental properties of biochars, the content of primary and secondary nutrients, as well as contaminants were examined and compared against the European Union Fertilizing Products Regulation. The biochars meet the specified limits for hydrogen-to-organic carbon ratio, chloride, and polycyclic aromatic hydrocarbons intended for gasification and pyrolysis component category materials. In six out of eight biochars, the content of phosphorus (P) as a single declared nutrient and the level of contaminants meet those required for an organo-mineral fertilizer. Only two biochars meet the required concentrations of nitrogen, phosphorus, and potassium. A minimum solid content of 30% in DPS is required to make the process of biochar production energetically sustainable. | |

Anaerobically digested sewage sludge mixed with forest residues was pyrolysed at 800 C, at laboratory and pilot scale. The study quantified differences in char and gas yields for tests carried out in a simple fixed bed laboratory reactor and rotating retort pyrolyser at pilot scale, when the residence time of feedstock was 10 min in both cases. The yield of char from pilot scale was 4 % lower than from laboratory scale while the yield of gas was 15.7 % higher. During the pilot scale pyrolysis of anaerobically digested sewage sludge blended with forest residues the gas quality for energy recovery applications was assessed and the fate of impurities (tar, NH3 and H2S) was investigated. The raw pyrolysis gas contained 14.6 g/Nm3 of tar, 36.9 g/Nm3 of NH3 and 793 ppm of H2S. Sixteen N-containing tar species were identified of which pyridine, propenenitrile, 2-methyl-, benzonitrile, and indole are found to be the most abundant. The yield of N-containing tar compounds accounted for approx. 12 % of total tar content. Conditioned pyrolysis gas contained 7.1 g/Nm3 of tar, 0.036 g/Nm3 of NH3 and 119 ppm of H2S. Benzene was by far the most abundant tar compound followed by toluene and styrene. The specifications of the used internal combustion engine were exceeded due to the sum of tar compounds such as fluorantrene and pyrene with 4+ aromatic rings (at 0.0015 g/Nm3) and NH3 content The effectiveness and sustainability of energy recovery in wastewater treatment can be improved using forest industry by-products. | |

Adsorption of six contaminants of emerging concern (CECs) - caffeine, chloramphenicol, carbamazepine, bisphenol A, diclofenac, and triclosan - from a multicomponent solution was studied using activated biochars obtained from three lignocellulosic feedstocks: wheat straw, softwood, and peach stones. Structural parameters related to the porosity and ash content of activated biochar and the hydrophobic properties of the CECs were found to influence the adsorption efficiency. For straw and softwood biochar, activation resulted in a more developed mesoporosity, whereas activation of peach stone biochar increased only the microporosity. The most hydrophilic CECs studied, caffeine and chloramphenicol, displayed the highest adsorption (22.8 and 11.3 mg g-1) onto activated wheat straw biochar which had the highest ash content of the studied adsorbents (20 wt%). Adsorption of bisphenol A and triclosan, both relatively hydrophobic substances, was highest (31.6 and 30.2 mg g-1) onto activated biochar from softwood, which displayed a well-developed mesoporosity and low ash content. | |

Magnetic carbons can significantly lower the costs of wastewater treatment due to easy separation of the adsorbent. However, current production techniques often involve the use of chlorinated or sulfonated Fe precursors with an inherent potential for secondary pollution. In this study, ochre, an iron-rich waste stream was investigated as a sustainable Fe source to produce magnetic activated biochar from two agricultural feedstocks, softwood and wheat straw. Fe doping resulted in significant shifts in pyrolysis yield distribution with increased gas yields (+50%) and gas energy content (+40%) lowering the energy costs for production. Physical activation transformed ochre to magnetite/maghemite resulting in activated magnetic biochars and led to a 4-fold increase in the adsorption capacities for two common micropollutants - caffeine and fluconazole. The results show that Fe doping not only benefits the adsorbent properties but also the production process, leading the way to sustainable carbon adsorbents. | |

The majority of the sludge from the treatment of wastewater in milk processing plants is land spread. The drawbacks of land spreading include local oversupply due to high transport costs, which results in sludge being spread on lands in the vicinity of the dairy factories. Local oversupply can lead to accumulation of certain substances in soil through annual application over many years. Therefore, in the long term, there is a need for alternative methods to recover energy and nutrients from increasing volumes of sludge generated from dairy processing. Pyrolysis offers a potential alternative to land spreading, which can reduce health and environmental risks, while providing an avenue for the recovery of energy and nutrients. Pyrolysis allows energy recovery in the form of a high calorific value pyrolysis gas and a char which may be used as a soil amendment. In this study pyrolysis of dried dairy sludge was carried out at pilot scale. The results indicate that a dried biological sludge can be successfully pyrolysed and when mixed with wood the resulting char meets European Biochar Certificate criteria regarding carbon content. Most of the initial energy content of the feedstock was retained in the pyrolysis gas prior to cleaning, 53%, compared to 34.5% in the char and 1.5% in the tar. For the pyrolysis gas after cleaning (mainly cracking in presence of air) the initial energy content of the feedstock retained in the gas was only slightly higher than that retained in the char, 39.2% versus 34.5%, while the tar accounted for 0.8% of the initial energy content. | |

Eucalypts can be very productive when intensively grown as short rotation woody crops (SRWC) for bioproducts. In Florida, USA, a fertilized, herbicided, and irrigated cultivar planted at 2471 trees/ha could produce over 58 green mt/ha/year in 3.7 years, and at 2071 trees/ha, its net present value (NPV) exceeded $750/ha at a 6% discount rate and stumpage price of $11.02/green mt. The same cultivar grown less intensively at three planting densities had the highest stand basal area at the highest density through 41 months, although individual tree diameter at breast height (DBH) was the smallest. In combination with an organic fertilizer, biochar improved soil properties, tree leaf nutrients, and tree growth within 11 months of application. Biochar produced from Eucalyptus and other species is a useful soil amendment that, especially in combination with an organic fertilizer, could improve soil physical and chemical properties and increase nutrient availability to enhance Eucalyptus tree nutrition and growth on soils. Eucalypts produce numerous naturally occurring bioproducts and are suitable feedstocks for many other biochemically or thermochemically derived bioproducts that could enhance the value of SRWCs. | |