Alkali Pretreatment of Biomass

Background

Lignocellulosic Biomass

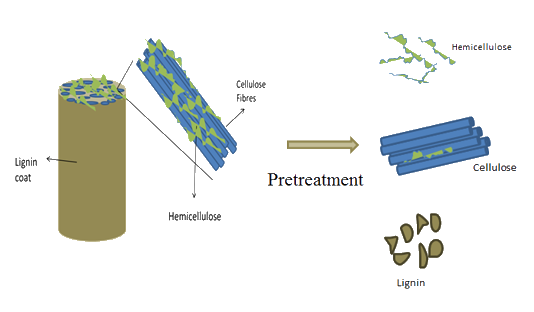

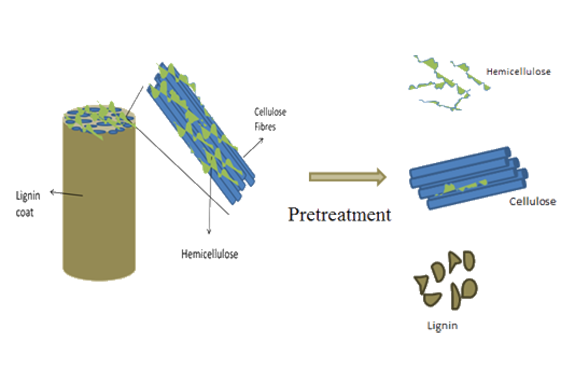

Lignocellulosic biomass is defined as a plant, or plant-derived, material that is mostly composed of cellulose, hemicellulose, and lignin. Lignocellulosic feedstocks are highly abundant, covering many biomass types including grasses, wood, energy crops (e.g. Miscanthus and coppices), agricultural residues (e.g. straws and corn stover), and municipal wastes.Lignocellulosic feedstocks are highly abundant and can often be sourced sustainably, at low cost, without leading to land-use conflicts. As a result, there is currently great interest in obtaining chemicals, fuels, and biomaterials from such biomass.

However, the hydrolysis of lignocellulosic polysaccharides is not easy and is influenced by the complex inter-associations between hemicellulose and cellulose and between these polysaccharides and lignin in the lignocellulosic matrix. In particular, the crystalline nature of much cellulose and the existence of a physical barrier of lignin surrounding the cellulose fibres are said to be major contributors to the recalcitrance of cellulose.

The mechanism of hydrolysis is further complicated by the fact that different process intensities are required for the hydrolysis of cellulose versus hemicellulose. The more intense conditions required for cellulose hydrolysis may degrade the sugars hydrolysed from hemicellulose (to products such as furfural and formic acid).

For this reason, most hydrolysis technologies employ pre-treatment processes that aim to break apart the matrix (and in particular the associations between lignin and cellulose), reduce cellulose crystallinty, and hydrolyse hemicelluloses, hence separating the hydrolysate from cellulose which can then undergo more severe/targeted treatment.

Get more info...Biomass Hydrolysis

Need for Pretreatment

For this reason, most hydrolysis technologies employ pre-treatment processes that aim to break apart the matrix (and in particular the associations between lignin and cellulose), reduce cellulose crystallinty, and hydrolyse hemicelluloses, hence separating the hydrolysate from cellulose which can then undergo more severe/targeted treatment.Get more info...Pretreatment Homepage

Alkali Pretreatment

One of the primary targets of alkali pretreatment is the removal and/or modification of lignin. Alkali substances are able to disrupt and solubilize lignin structures, which are more susceptible to alkaline conditions compared with cellulose or hemicellulose. The removal of lignin opens up the plant cell wall structure and increases the accessibility of cellulose and hemicellulose to enzymes.

Another impact of alkali pretreatment on hemicellulose is that it can reduce the acetyl groups present. This is also beneficial for subsequent enzymatic hydrolysis.

Alkali pretreatment also causes swelling of the hemicellulose and cellulose structures, increasing their surface area and making them more susceptible to enzymatic attack.

Effects of Different Alkali-Pretreatment Conditions

- Type and Concentration of Alkali - Different alkalis (e.g. NaOH, KOH, NH4OH, Ca(OH)2) have different reactivity with the biomass components, and this can influence the extent of lignin removal and cellulose accessibility. The concentration of the alkali also plays a major role. Higher concentrations can lead to greater disruption of the biomass structure, but also increased costs and potential environmental impacts.

- Temperature - Higher temperatures can increase the rate of the alkali pretreatment reactions, leading to more effective disruption of the biomass structure and potentially higher sugar yields in the subsequent hydrolysis step. However, very high temperatures can also lead to degradation of the sugars and formation of inhibitory compounds.

- Reaction Time - Longer reaction times can allow for more complete reactions, leading to greater disruption of the biomass and potentially higher sugar yields. However, extended reaction times can also increase the risk of sugar degradation, and they require more energy, which can increase costs.

- Liquor Ratio - The ratio of liquid to solid biomass can influence the effectiveness of the pretreatment. Higher liquor ratios can improve the diffusion of the alkali into the biomass and the removal of solubilized components, but they also require more alkali and larger reaction vessels.

- Biomass Particle Size - Smaller particle sizes typically lead to higher sugar yields, as they provide a greater surface area for the alkali to interact with the biomass. However, very small particles can lead to issues with mixing and mass transfer.

- Agitation - Agitation can enhance mass transfer and lead to more uniform pretreatment, potentially improving sugar yields.

Feedstock Considerations in Alkali Pretreatment

- Extractives - The content and composition of the extractives is important in alkali pretreatment for several reasons. Firstly, extractives can react with alkali, potentially reducing the amount of alkali available for disrupting lignin and hemicellulose structures. This could reduce the overall effectiveness of the pretreatment. Secondly, some extractives can be converted into inhibitory compounds during alkali pretreatment. These compounds can inhibit subsequent enzymatic hydrolysis and fermentation processes. The risk of this can depend on the specific types of extractives present in the biomass. Thirdly, in other scenarios alkali pretreatment can help to remove many extractives from the biomass which can be beneficial in cases where otherwise the extractives would inhibit subsequent enzymatic hydrolysis and fermentation processes.

- Hemicellulose Type - Alkali can lead to partial solubilization of hemicelluloses, which can improve the accessibility of cellulose. The exact effect depends on the type of hemicellulose (e.g. xylans, mannans), with some types being more susceptible to alkali than others.

- Lignin Type - Different types of lignin (i.e. guaiacyl, syringyl, and p-hydroxyphenyl lignin) may respond differently to alkali. For example, hardwood lignin (which is rich in syringyl units) is often more susceptible to alkali treatment than softwood lignin (which contains mostly guaiacyl units). It should be noted that lignin can consume a significant amount of alkali during pretreatment, particularly if the biomass has a high lignin content.

- Lignin-Carbohydrate Complexes (LCCs) - Alkali pretreatment can break the linkages between lignin and carbohydrates, enhancing the accessibility of cellulose and hemicellulose to enzymatic hydrolysis. The type and degree of these LCC linkages can vary depending on the type of biomass and can influence the effectiveness of the pretreatment.

- Ash Content and Composition - Inorganic components, such as minerals and salts, can affect the pH of the system and potentially interact with the alkali, affecting its availability for reactions with the biomass components.

Advantages of Alkali Pretreatment

- Effective Lignin Removal - Alkali pretreatment is especially effective at solubilizing and removing lignin. This leaves a solid component containing mostly polysaccharides and the potential for recovering the lignin from the liquid phase.

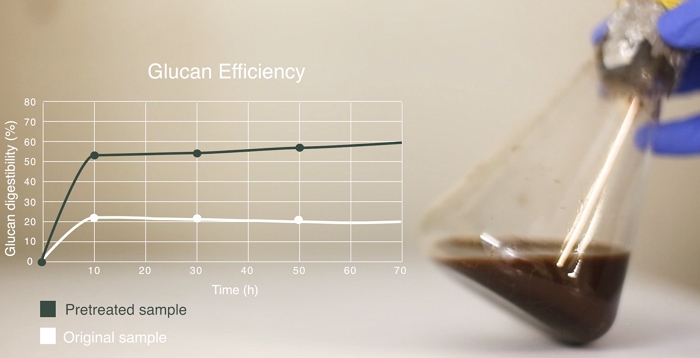

- Increased Enzymatic Digestibility - By disrupting the lignin structure and partially solubilizing hemicellulose, alkali pretreatment increases the digestibility of the biomass. This can lead to higher yields of fermentable sugars during the subsequent hydrolysis step.

- Reduced Formation of Inhibitory Compounds - Compared to acid-based pretreatments, alkali pretreatment typically results in lower formation of inhibitory compounds such as furfural and hydroxymethylfurfural (HMF). These compounds can hinder subsequent enzymatic hydrolysis and fermentation.

- Lower Operating Temperatures - Alkali pretreatment can be effective at lower temperatures compared to some other pretreatment methods, potentially reducing energy costs.

- Versatility - Alkali pretreatment can be effective for a wide variety of different types of lignocellulosic biomass.

- Improvement of Lignin for Downstream Applications - The alkali pretreatment process can modify lignin into forms that may be more suitable for downstream applications, potentially adding value to this byproduct.

Disadvantages of Alkali Pretreatment

- Alkali Cost and Handling - Alkali reagents, such as sodium hydroxide or potassium hydroxide, can be expensive and require special handling and safety precautions due to their corrosive nature.

- Waste Disposal and Environmental Impact - The spent alkali liquor may contain solubilized lignin, hemicellulose, and other byproducts that require proper disposal or treatment. Additionally, large amounts of alkali salts can be generated, which could have significant environmental impacts if not managed properly.

- Neutralization Requirement - After alkali pretreatment, the resulting biomass slurry is typically highly alkaline and needs to be neutralized before it can be used for enzymatic hydrolysis and fermentation. This neutralization step can add complexity and cost to the process.

- Loss of Hemicellulosic Sugars - Alkali pretreatment can lead to the solubilization and loss of some hemicellulosic sugars. This can reduce the total yield of fermentable sugars from the biomass.

- Long Reaction Times - Alkali pretreatment often requires longer reaction times than other pretreatment methods, particularly if it is performed at lower temperatures. This can reduce the overall throughput of the process.

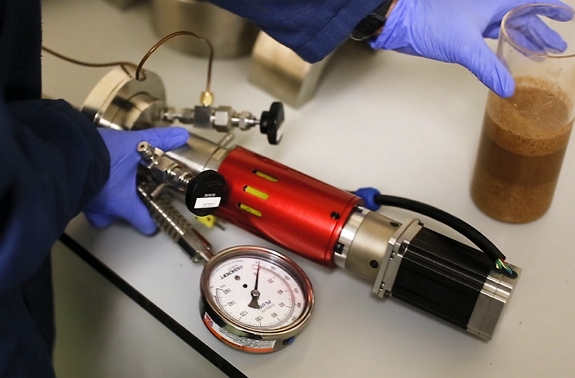

Alkali Pretreatment Bioprocess Development at Celignis

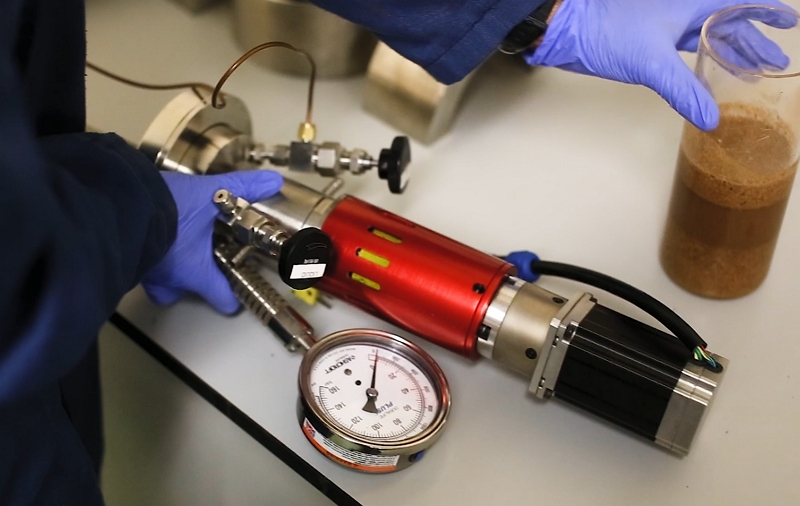

Our initial step would involve learning from you what your targets are for the pretreatment and what the subsequent stages of the process, and final products, should be.

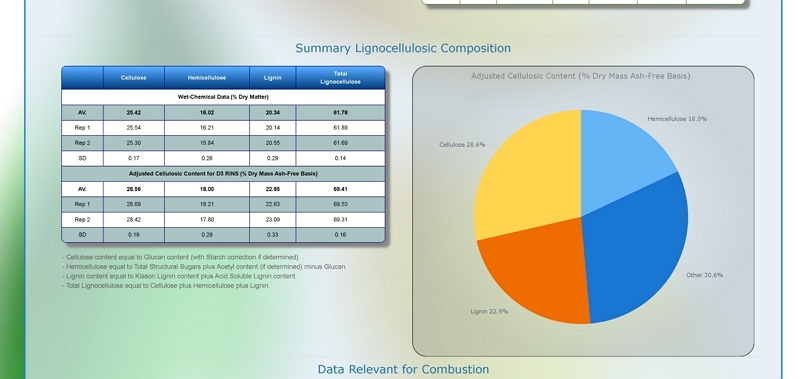

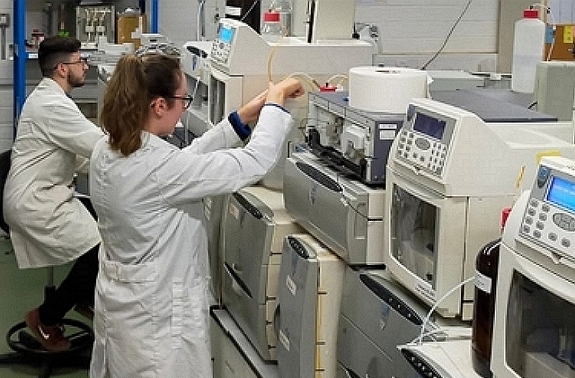

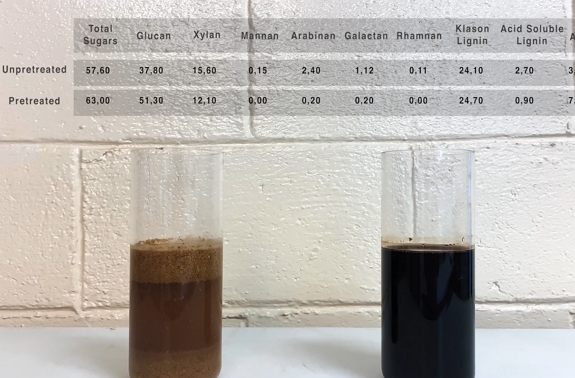

Then we would undergo a detailed compositional analysis of the feedstock in order to gain an understanding of its suitability for alkali pretreatment and to consider appropriate process conditions.

There would be detailed analysis of the liquid and solid outputs of these pretreatments, comparing these results with the targeted aims of the pretreatment and downstream valorisation.

If there are also plans for downstream valorisation of the liquid fraction we can also assess the suitability of various hydrolysates from the DoE for such processes.

The commercial viability of pretreatment is particularly important and should be considered throughout the project. We usually recommend to our clients that we undertake interative techno-economic analyses (TEA) at various stages of the bioprocess development, so that the experimental and scale-up work are framed in a commercially-relevant context.

Get more info...How our Bioprocess Projects Work

Other Types of Biomass Pretreament

Get more info...Mechanical Pretreatment

Get more info...Steam Pretreatment

Get more info...Hydrothermal Pretreatment

Get more info...Acid Pretreatment

Get more info...Organosolv Pretreatment

Get more info...Other Pretreatments

Get more info...Pretreatment Homepage

With regards to the pretreatment of biomass, the Celignis Bioprocess team members with the most experience in undertaking such projects are listed below. Feel free to contact them to discuss potential projects.

Lalitha Gottumukkala

Founder of Celignis Bioprocess, CIO of Celignis

PhD

<p style="text-align: left;">Has a deep understanding of all biological and chemical aspects of bioproceses. Has developed Celignis into a renowned provider of bioprocess development services to a global network of clients.</p>

Oscar Bedzo

Bioprocess Project Manager & Technoeconomic Analysis Lead

PhD

<p style="text-align: left;">A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.</p>

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

<p style="text-align: left;">Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.</p>