Organosolv Pretreatment of Biomass

Background

Lignocellulosic Biomass

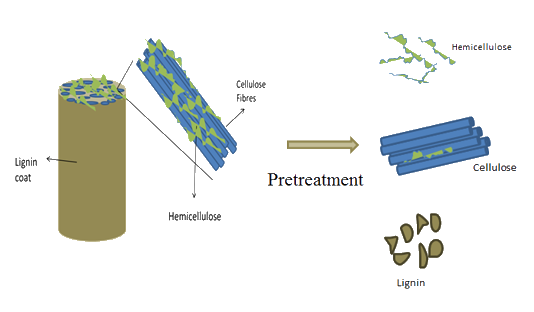

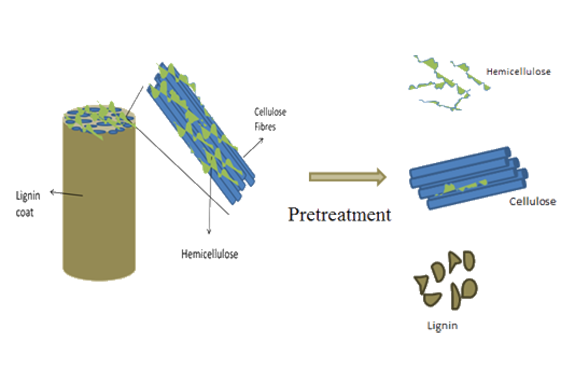

Lignocellulosic biomass is defined as a plant, or plant-derived, material that is mostly composed of cellulose, hemicellulose, and lignin. Lignocellulosic feedstocks are highly abundant, covering many biomass types including grasses, wood, energy crops (e.g. Miscanthus and coppices), agricultural residues (e.g. straws and corn stover), and municipal wastes.Lignocellulosic feedstocks are highly abundant and can often be sourced sustainably, at low cost, without leading to land-use conflicts. As a result, there is currently great interest in obtaining chemicals, fuels, and biomaterials from such biomass.

However, the hydrolysis of lignocellulosic polysaccharides is not easy and is influenced by the complex inter-associations between hemicellulose and cellulose and between these polysaccharides and lignin in the lignocellulosic matrix. In particular, the crystalline nature of much cellulose and the existence of a physical barrier of lignin surrounding the cellulose fibres are said to be major contributors to the recalcitrance of cellulose.

The mechanism of hydrolysis is further complicated by the fact that different process intensities are required for the hydrolysis of cellulose versus hemicellulose. The more intense conditions required for cellulose hydrolysis may degrade the sugars hydrolysed from hemicellulose (to products such as furfural and formic acid).

For this reason, most hydrolysis technologies employ pre-treatment processes that aim to break apart the matrix (and in particular the associations between lignin and cellulose), reduce cellulose crystallinty, and hydrolyse hemicelluloses, hence separating the hydrolysate from cellulose which can then undergo more severe/targeted treatment.

Get more info...Biomass Hydrolysis

Need for Pretreatment

For this reason, most hydrolysis technologies employ pre-treatment processes that aim to break apart the matrix (and in particular the associations between lignin and cellulose), reduce cellulose crystallinty, and hydrolyse hemicelluloses, hence separating the hydrolysate from cellulose which can then undergo more severe/targeted treatment.Get more info...Pretreatment Homepage

Organosolv Pretreatment

The aim of organosolv pretreatment is to fractionate the biomass into its three major components: cellulose, hemicellulose, and lignin. This allows for targeted separate valorisation approaches for each fraction.

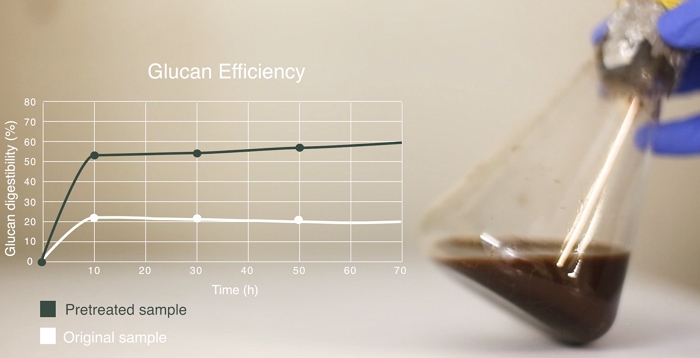

In particular, the purity of the separated lignin fraction and the enhanced suitability of the cellulose fraction for enzymatic hydrolysis are some of the advantages of using the organosolv approach.

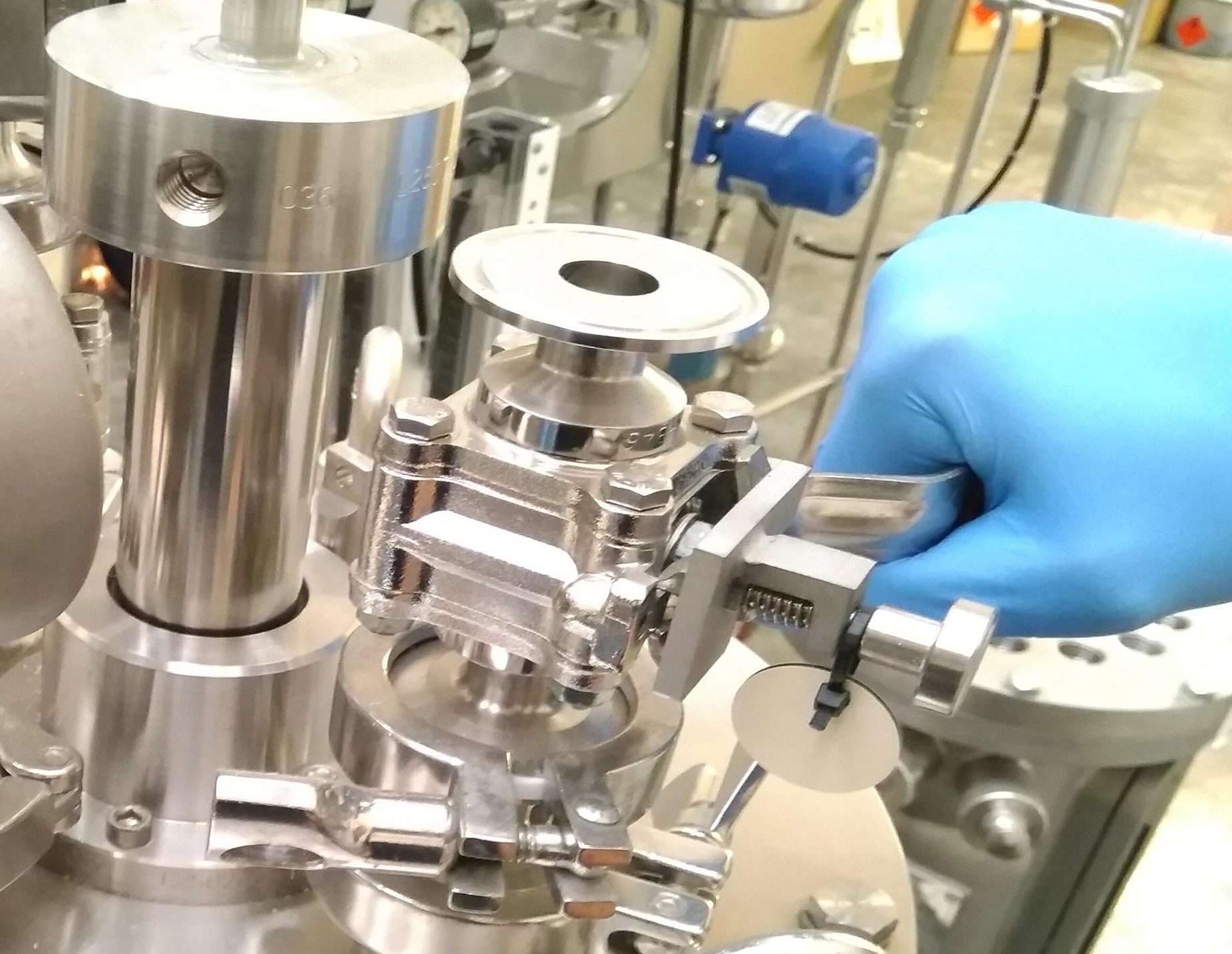

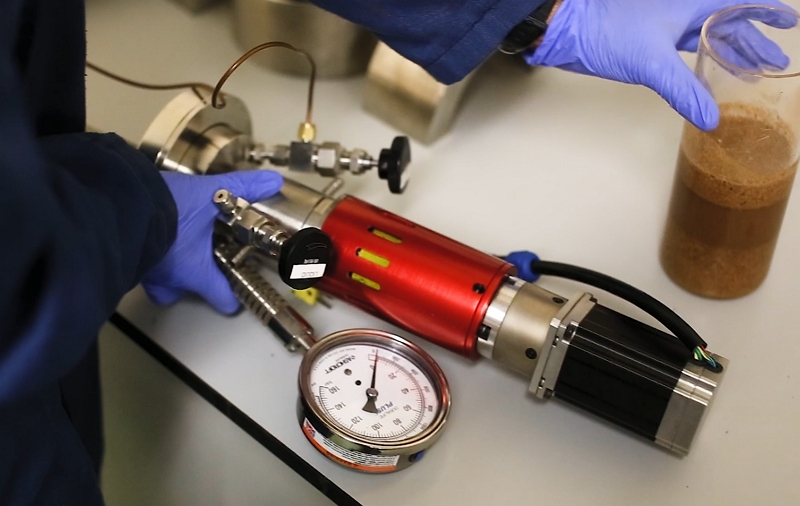

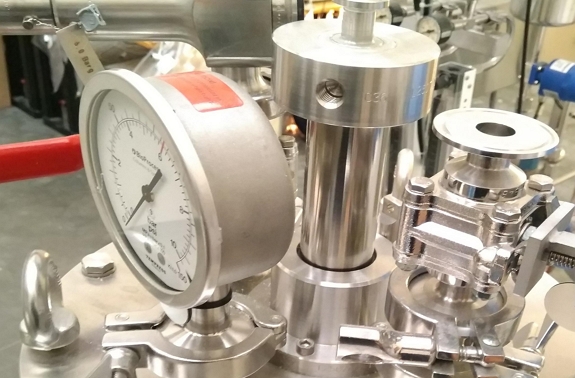

- Pretreatment - The biomass is mixed with an organic solvent or solvent mixture, typically at elevated temperatures and pressures.

- Fractionation - The organic solvent penetrates the biomass structure and solubilizes the lignin and some of the hemicellulose, leaving behind a cellulose-rich pulp. The solvent can also break the lignin-carbohydrate complexes (LCCs) that bind these components together in the plant cell wall, further enhancing the accessibility of cellulose.

- Recovery - After fractionation, the biomass-solvent mixture is typically separated into a solid fraction (the cellulose-rich pulp) and a liquid fraction (containing solubilized lignin, hemicellulose sugars, and solvent). These fractions can then be further processed separately.

Effects of Different Organosolv Pretreatment Conditions

- Choice of Solvent - The type of organic solvent used can greatly influence: the efficiency of lignin removal; whether hemicellulose is also removed and in what form it exists (e.g. as a polymer or monomers); and the preservation of cellulose in the solid phase. For example, organosolv pretreatment using ethanol as the solvent results in extraction and partial hydrolysis (to a mix of oligomers and polymers) of hemicellulose whilst organosolv pretreatment using tetrahydrofuran (THF) as the solvent extracts hemicellulose as a polymer.

- Temperature and Pressure - Higher temperatures and pressures generally improve the efficiency of organosolv pretreatment by increasing the solubility of lignin and reducing the time required for effective pretreatment. However, extreme conditions can also lead to degradation of the sugars in cellulose and hemicellulose, leading to lower yields.

- Reaction Time - Longer reaction times can allow for more thorough delignification and separation of biomass components, but they can also lead to greater sugar degradation if conditions are too harsh.

- Solvent Concentration - Higher solvent concentrations can increase the efficiency of lignin removal, but they can also lead to higher costs and potentially greater environmental impacts.

- Catalyst Use - Acidic or alkaline catalysts can be used to enhance the organosolv process. Acid catalysts can enhance hemicellulose hydrolysis and lignin solubilization, while alkaline catalysts can promote lignin disruption. However, the use of catalysts adds complexity and may require additional steps for catalyst recovery and neutralization.

- Particle Size - Smaller particle sizes increase the surface area of biomass exposed to the solvent, improving the efficiency of the organosolv process. However, reducing the particle size requires additional energy input.

Feedstock Considerations in Organosolv Pretreatment

- Extractives - The content and composition of the extractives is important in organosolv pretreatment for several reasons. Firstly, extractives can interact with the solvents used in the organosolv process, potentially altering the solvent's effectiveness at solubilizing lignin and hemicellulose. Some extractives might be soluble in the solvent, which could dilute the solvent or change its properties, while others might not be soluble, which could lead to the formation of a separate phase or residues. Secondly, certain extractives can bind with lignin, making it more difficult to remove from the biomass during the pretreatment and so reducing process efficiency. Thirdly, some extractives can degrade or react under the pretreatment conditions to form compounds that are inhibitory to subsequent enzymatic hydrolysis or fermentation processes. Finally, the presence of extractives in the pretreatment liquor can also affect the quality of the co-products obtained, such as lignin. If the extractives are soluble in the solvent, they might contaminate the lignin fraction, making it less suitable for certain downstream applications. As a result of all of these issues associated with extractives, it may be necessary to employ a pre-pretreatment step to remove extractives prior to the organosolv pretreatment. However, this may increase the cost and complexity of the process.

- Hemicellulose Type - Different types of hemicellulose exhibit different solubility characteristics in various organosolv solvents. The solubility of hemicellulose influences its extraction efficiency during pretreatment. For example, xylans in hardwoods or agricultural residues might be more easily solubilized than the glucomannans often found in softwoods.

- Lignin Type - Different types of lignin (like guaiacyl, syringyl, and p-hydroxyphenyl lignin) have different solubility in various organosolv solvents. For instance, hardwood lignin, which has a high proportion of syringyl units, is typically more soluble in organosolv solvents than softwood lignin, which is rich in guaiacyl units. Additionally, the type of lignin can influence the quality of the lignin fraction recovered after the organosolv pretreatment. Certain types of lignin might be less degraded or contaminated by the pretreatment, leading to a high-quality lignin that can be used for high-value applications.

- Ash Content and Composition - Inorganic compounds can interact with the organosolv solvents and potentially influence the pretreatment process and the quality of the fractions obtained.

Advantages of Organosolv Pretreatment

- Efficient Biomass Fractionation - Organosolv pretreatment effectively fractionates biomass into its primary components: cellulose, hemicellulose, and lignin. This facilitates further conversion processes, as each component can be processed separately, optimising yields and quality.

- High-Purity Lignin - One of the most valuable advantages of the organosolv process is the production of high-purity lignin. This lignin is largely free of sugar residues and can be further utilised in various applications, including the production of bio-based materials or chemicals.

- Reduced Inhibitor Formation - Organosolv pretreatment typically results in fewer inhibitory by-products compared to other pretreatment methods, such as dilute acid pretreatment. This can lead to improved efficiency in subsequent fermentation processes.

- Reduced Enzyme Loading (Downstream) - By removing lignin and hemicellulose, organosolv pretreatment enhances the accessibility of cellulose, reducing the enzyme loading required for efficient hydrolysis.

Disadvantages of Organosolv Pretreatment

- Cost of Solvent - Organic solvents used in the process, like ethanol or acetone, can be expensive. Although the solvent can be recycled, the recovery rate is not 100% and the recycling process itself adds to the overall cost.

- Energy Consumption - Organosolv pretreatment often requires high temperatures and pressures, leading to high energy consumption, which adds to the operating cost and environmental impact of the process.

- Inhibitor Formation - Despite generally lower inhibitor formation compared to other pretreatment methods, some inhibitory compounds can still be formed during organosolv pretreatment, especially under severe conditions. These inhibitors can hinder subsequent enzymatic hydrolysis or fermentation processes.

- Equipment Corrosion - The use of organic solvents at high temperatures and pressures can lead to corrosion of equipment, necessitating the use of specialized, more expensive materials in construction.

- Regulatory Issues - Depending on the location and scale of the operation, the use, storage, and disposal of organic solvents might be subject to strict regulatory requirements due to potential safety and environmental concerns.

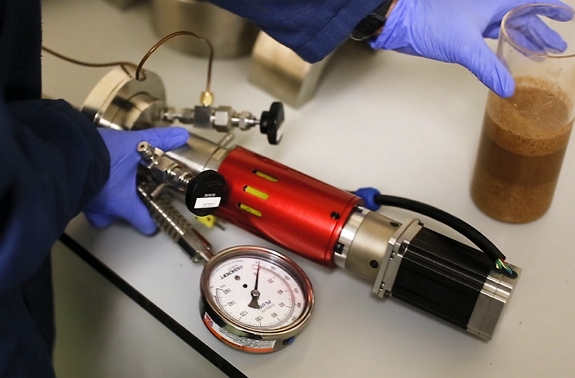

Organosolv Pretreatment Bioprocess Development at Celignis

Our initial step would involve learning from you what your targets are for the pretreatment and what the subsequent stages of the process, and final products, should be.

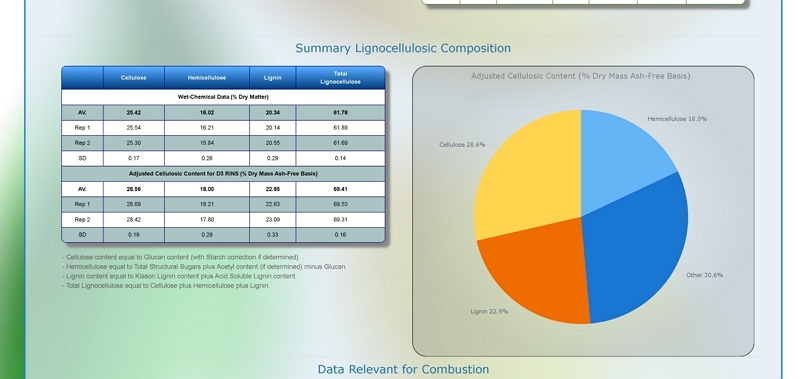

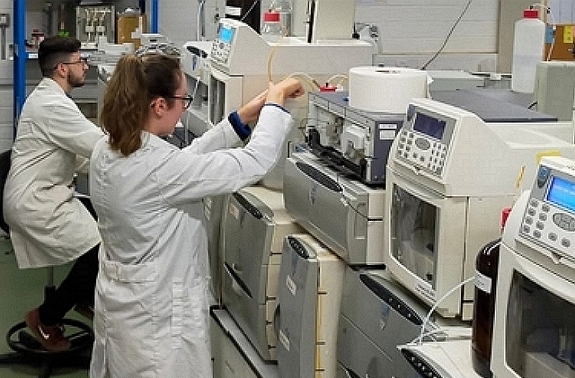

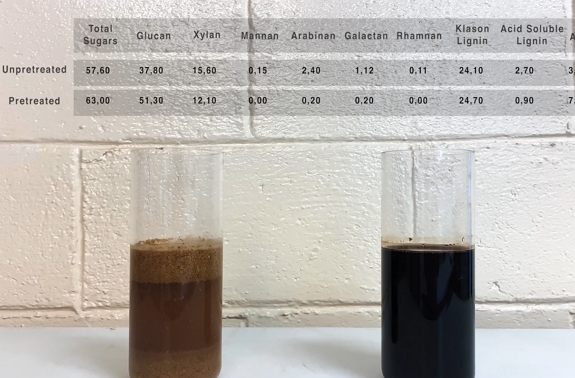

Then we would undergo a detailed compositional analysis of the feedstock in order to gain an understanding of its suitability for alkali pretreatment and to consider appropriate process conditions.

There would be detailed analysis of the liquid and solid outputs of these pretreatments, comparing these results with the targeted aims of the pretreatment and downstream valorisation.

If there are also plans for downstream valorisation of the liquid fraction we can also assess the suitability of various hydrolysates from the DoE for such processes.

The commercial viability of pretreatment is particularly important and should be considered throughout the project. We usually recommend to our clients that we undertake interative techno-economic analyses (TEA) at various stages of the bioprocess development, so that the experimental and scale-up work are framed in a commercially-relevant context.

Get more info...How our Bioprocess Projects Work

Other Types of Biomass Pretreament

Get more info...Mechanical Pretreatment

Get more info...Steam Pretreatment

Get more info...Hydrothermal Pretreatment

Get more info...Acid Pretreatment

Get more info...Acid Pretreatment

Get more info...Other Pretreatments

Get more info...Pretreatment Homepage

With regards to the pretreatment of biomass, the Celignis Bioprocess team members with the most experience in undertaking such projects are listed below. Feel free to contact them to discuss potential projects.

Lalitha Gottumukkala

Founder of Celignis Bioprocess, CIO of Celignis

PhD

Has a deep understanding of all biological and chemical aspects of bioproceses. Has developed Celignis into a renowned provider of bioprocess development services to a global network of clients.

Oscar Bedzo

Bioprocess Project Manager & Technoeconomic Analysis Lead

PhD

A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.