Upgrading of Biochar and Biochar Bioprocess Development

However, the properties of raw biochar can vary widely depending on the feedstock and pyrolysis conditions, and may not always be suitable for specific applications. Therefore, upgrading biochar is often necessary to enhance its properties and tailor it to specific market needs.

Reasons for Upgrading Biochar

- Enhancing Physicochemical Properties: Raw biochar can have a wide range of properties, such as surface area and porosity, pH, and elemental composition, that may not be optimal for its intended application. Upgrading biochar can enhance these properties to improve its performance and efficacy in specific market applications.

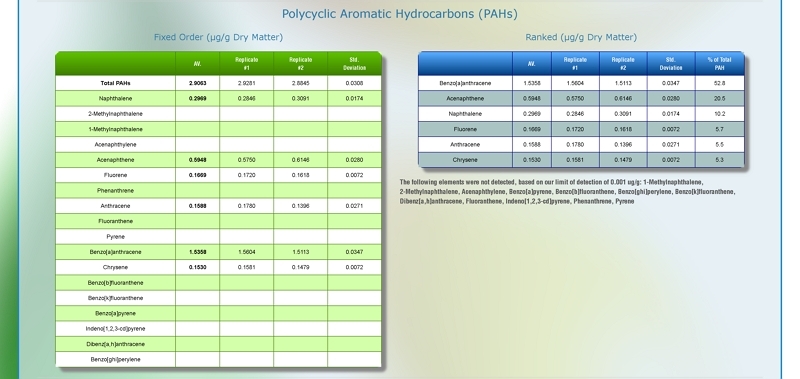

- Reducing Toxic Compounds: Some biochars may contain toxic compounds, such as heavy metals or polycyclic aromatic hydrocarbons (PAHs), which can pose risks to human health and the environment. Upgrading techniques can help to reduce or remove these harmful substances, ensuring the safety and sustainability of biochar applications.

- Customization for Market Needs: Upgrading biochar allows for the customization of its properties to meet the specific requirements of various market applications, such as agriculture, environmental remediation, energy production, or construction materials. Tailoring biochar properties to these applications can enhance its market value and competitiveness.

Market Applications for Upgraded Biochar

- Agriculture: Biochars with enhanced nutrient content, pH, and cation exchange capacity can improve soil fertility and crop productivity when used as soil amendments. Surface-functionalized biochars can also serve as carriers for slow-release fertilizers or plant growth-promoting microorganisms.

- Environmental Remediation: Upgraded biochars with high surface area, porosity, and adsorption capacity can effectively remove contaminants, such as heavy metals, organic pollutants, and nutrients, from soil and water. Surface-functionalized biochars can also be tailored for selective adsorption of specific contaminants or used as catalysts in advanced oxidation processes.

- Energy Production: Upgraded biochars with improved calorific value, mechanical strength, and combustion properties can be used as an alternative to fossil fuels in energy production, such as co-firing in power plants or biomass gasification.

- Construction Materials: Upgraded biochars blended with other materials can be used as lightweight aggregates, insulating materials, or reinforcing fillers in the production of concrete, bricks, and other construction materials. Biochar-based composites can also contribute to carbon sequestration and reduce the environmental impact of traditional construction materials.

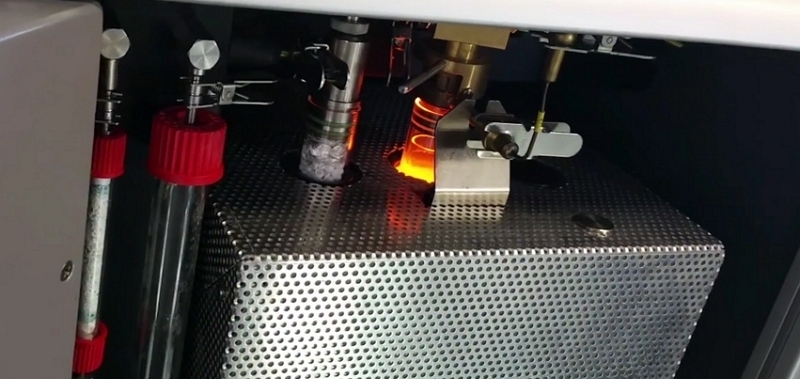

Physical Activation

This involves the treatment of biochar with steam or carbon dioxide at high temperatures (800-1000 oC) to increase its surface area and porosity. This method can improve biochar's adsorption capacity and is particularly beneficial for applications in wastewater treatment and gas purification. However, physical activation can be energy-intensive and may lead to carbon loss, reducing the carbon sequestration potential of biochar.Chemical Activation

This involves impregnating biochar with chemical agents, such as potassium hydroxide (KOH), sodium hydroxide (NaOH), or phosphoric acid (H3PO4), followed by heat treatment at lower temperatures (400-800oC) compared to physical activation. This process can increase biochar's surface area and porosity, enhancing its performance in adsorption and catalysis applications. The main disadvantage of chemical activation is the use of hazardous chemicals and the need for post-treatment to remove residual activation agents.Acid/Base Washing

Here biochar is treated with acidic or alkaline solutions to modify its surface properties and remove impurities, such as heavy metals or ash. This technique can improve biochar's pH and cation exchange capacity (CEC), making it more suitable for applications in soil amendment and environmental remediation. However, acid/base washing can be resource-intensive, as it requires large volumes of water and produces wastewater that needs to be treated and disposed of properly.Thermal Post-Treatment

This involves the further heating of biochar under an inert atmosphere. This process can remove volatile organic compounds (VOCs) and increase the carbon content of biochar, enhancing its stability and carbon sequestration potential. The main disadvantage of thermal post-treatment is the additional energy consumption, which can increase the overall production costs of biochar. Additionally, over-treatment can lead to a reduction in biochar's surface area and porosity, potentially diminishing its performance in certain applications.Surface Functionalisation

In surface functionalization, the surface chemistry of biochar is modified through the attachment of specific functional groups, such as hydroxyl, carboxyl, or amine groups. This can be achieved through chemical or biological methods, such as oxidation, amination, or enzymatic treatment. Surface functionalization can improve biochar's adsorption capacity, selectivity, and reactivity, making it more suitable for applications in environmental remediation, catalysis, and agriculture. However, some surface functionalization techniques can be complex, time-consuming, and expensive, limiting their scalability and commercial viability.Blending and Composting

Here biochar is mixed with other materials, such as natural or synthetic polymers, minerals, or organic compounds, to create composite materials with enhanced properties. This approach can improve biochar's mechanical strength, nutrient content, and water holding capacity, making it more suitable for applications in construction materials, soil amendment, and erosion control. The main disadvantage of blending and compositing is the potential for increased production costs and complexity, as well as the need for careful selection and compatibility of the blended materials.Biochar Upgrading

Based on your starting feedstock or biochar and your targeted market we can formulate a bespoke approach for the upgrading of biochar for improved properties and enhanced value. We have the infrastructure and expertise to undertake all the upgrading approaches described above. Our experts will formulate an experimental plan for testing and optimising biochar upgrading strategies.Testing Upgraded Biochar for Desired Market Applications

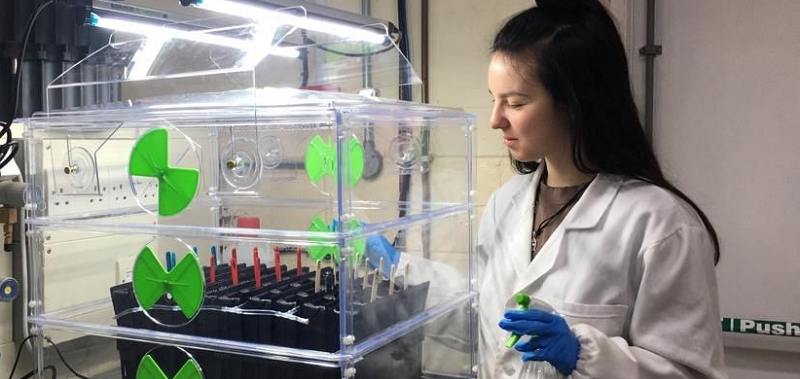

We have a wide array of equipment and analysis packages to fully evaluate the chemical and physical properties of your upgraded biochar. Examples of such analyses include: surface area and porosity, water holding capacity, cation exchange capacity, and carbon content and stability. In many biochar upgrading projects the tests results will feed-back to our upgrading experiments so that we can seee the effects of process conditions on biochar properties, allowing for the process to be optimised in an iterative and cost-effective manner.

Sajna KV

Bioanalysis Head

PhD

<p style="text-align: left;">Our Biomass Detective! Designs, tests, optimizes and validates robust analytical methods for properties of relevance to the various biochar market applications.</p>

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

<p style="text-align: left;">Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.</p>

Lalitha Gottumukkala

Chief Innovation Officer

PhD

<p style="text-align: left;">A serial innovator managing multiple projects. Has particular expertise related to the upgrading of biochar and on the assessment of its impact on plant productivity and soil health.</p>

Global Recognition as Biomass and Biochar Experts

Feedstock Evaluation

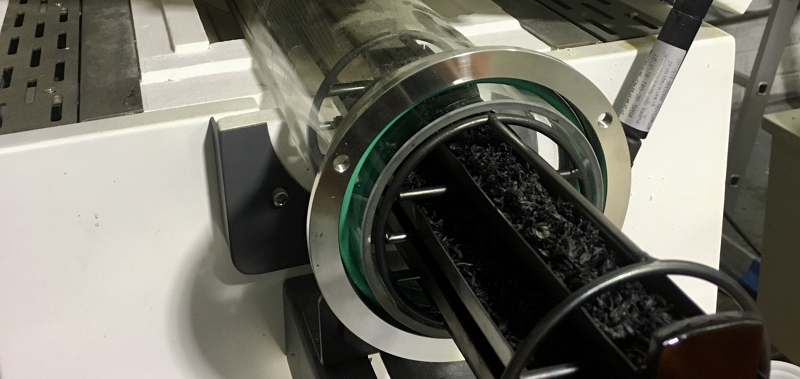

Biochar Production

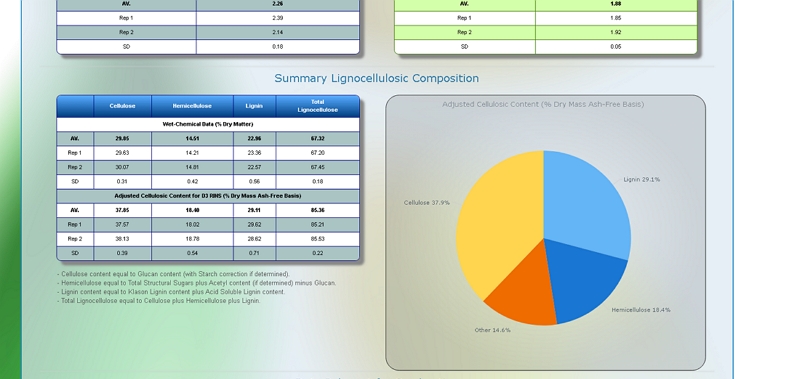

Biochar Analysis

Biochar Combustion Properties

Soil Amendment & Plant Growth Trials

Analysis of PAHs in Biochar

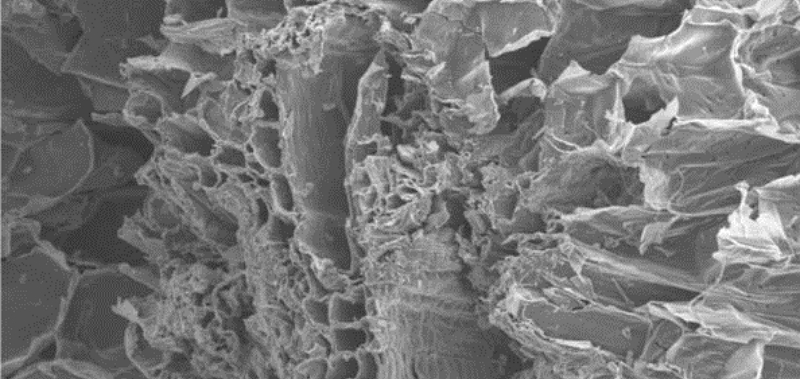

Surface Area and Porosity of Biochar

Thermogravimetric Analysis of Biochar

Biochar for Carbon Sequestration

Technoeconomic Analyses of Biochar Projects

Research Project Collaborations

Hydrothermal carbonization (HTC) research has mainly focused on primary char production, with limited attention to secondary char, which is formed through polymerization and condensation of dissolved organic compounds in the liquid phase. This research aims to address this gap via an experimental investigation of the impact of stirring on the mass and carbon balance of HTC reaction products, surface functional groups, and surface morphology of secondary char, using fructose as a model compound. A 3D hydrodynamic simulation model was developed for a two-liter HTC stirred reactor. The experimental results indicated that stirring did not significantly influence the pH, mass, carbon balance, and surface functional groups of secondary char produced under the range of experimental conditions (180 C, 10% biomass to water (B/W) ratio, and a residence time of 0-120 min) studied. Nonetheless, it was observed that a stirring rate of 200 rpm influenced the morphology and shape of the secondary char microspheres, leading to a significant increase in their size i.e., from 1-2 um in unstirred conditions compared with 70 um at a stirring rate of 200 rpm. This increase in size was attributed to the aggregation of microspheres into irregular aggregates at stirring rates > 65 rpm and residence times > 1 h. The hydrodynamic model revealed that high turbulence of Re > 104 and velocities > 0.17 m s-1 correlated with regions of secondary char formation, emphasizing their role in particle aggregation. Particle aggregation is significant above a stirring rate of 65 rpm, which corresponds to the onset of turbulent flow in the reactor. Finally, a mechanism is proposed, based on reactor hydrodynamics under stirred conditions, that explains secondary char deposition on the reactor walls and stirrer. | |

A dried dairy processing sludge (sludge from wastewater treatment of an effluent from a milk processing plant) was pyrolysed in a single-particle reactor at different temperatures from 400 C to 900 C. NH3 and HCN were measured online and offline by means of FTIR as well as by cumulative sampling in impinger bottles (in 0.05 M H2SO4 and 1 M NaOH, respectively) and analysed by photometric method. NO and NO2 were measured online using a nitric oxide analyser while N2O was measured by FTIR. Nitrogen (N) in the sludge and in the remaining char, char-N, was determined. Moreover, tar content in pyrolysis gas was measured and tar-N was determined. The results with respect to N mass balance closure are discussed. The different measurements techniques are compared. For pyrolysis at 520 and 700 nitrogen in the gas phase was mainly contained as N2 (36 % and 40 % respectively), followed by NH3 (15 % and 18 %), tar-N (10 % and 9 %), HCN (1 % and 3 %), NO (1 %) and NO2 (0.2 %). The dairy processing sludge has very specific properties with organic-N present predominantly as proteins and a high content of inherent Ca. These characteristics affected the distribution of N. The amount of char-N was higher while the amount of tar-N lower than for sewage sludge from literature, at comparable pyrolysis temperature. | |

Dairy processing sludge (DPS) is a byproduct generated in wastewater treatment plants located in dairy (milk) processing companies (waste activated sludge). DPS presents challenges in terms of its management (as biosolids) due to its high moisture content, prolonged storage required, uncontrolled nutrient loss and accumulation of certain substances in soil in the proximity of dairy companies. This study investigates the potential of hydrothermal carbonization (HTC) for recovery of nutrients in the form of solid hydrochar (biochar) produced from DPS originating from four different dairy processing companies. The HTC tests were carried out at 160 C, 180 C, 200 C and 220 C, and a residence time of 1h. The elemental properties of hydrochars (biochars), the content of primary and secondary nutrients, as well as contaminants were examined. The transformation of phosphorus in DPS during HTC was investigated. The fraction of plant available phosphorus was determined. The properties of hydrochar (biochar) were compared against the European Union Fertilizing Products Regulation. The findings of this study demonstrate that the content of nutrient in hydrochars (biochars) meet the requirements for organo-mineral fertilizer with nitrogen and phosphorus as the declared nutrients (13.9-26.7%). Further research on plant growth and field tests are needed to fully assess the agronomic potential of HTC hydrochar (biochar). | |

Disposal of waste-activated sludge [dairy processing sludge, (DPS)] from wastewater treatment plants located in milk processing companies is an increasing concern. DPS is usually applied to farmlands in the vicinity of the dairy companies. This practice is becoming unsustainable due to uncontrolled nutrient loss and potential soil contamination. We propose to recover nutrients in the form of biochar. This paper examines the properties of biochars obtained from slow pyrolysis of DPS. DPS samples were pyrolyzed at laboratory and pilot scale at 600 and 700 C. The elemental properties of biochars, the content of primary and secondary nutrients, as well as contaminants were examined and compared against the European Union Fertilizing Products Regulation. The biochars meet the specified limits for hydrogen-to-organic carbon ratio, chloride, and polycyclic aromatic hydrocarbons intended for gasification and pyrolysis component category materials. In six out of eight biochars, the content of phosphorus (P) as a single declared nutrient and the level of contaminants meet those required for an organo-mineral fertilizer. Only two biochars meet the required concentrations of nitrogen, phosphorus, and potassium. A minimum solid content of 30% in DPS is required to make the process of biochar production energetically sustainable. | |

Anaerobically digested sewage sludge mixed with forest residues was pyrolysed at 800 C, at laboratory and pilot scale. The study quantified differences in char and gas yields for tests carried out in a simple fixed bed laboratory reactor and rotating retort pyrolyser at pilot scale, when the residence time of feedstock was 10 min in both cases. The yield of char from pilot scale was 4 % lower than from laboratory scale while the yield of gas was 15.7 % higher. During the pilot scale pyrolysis of anaerobically digested sewage sludge blended with forest residues the gas quality for energy recovery applications was assessed and the fate of impurities (tar, NH3 and H2S) was investigated. The raw pyrolysis gas contained 14.6 g/Nm3 of tar, 36.9 g/Nm3 of NH3 and 793 ppm of H2S. Sixteen N-containing tar species were identified of which pyridine, propenenitrile, 2-methyl-, benzonitrile, and indole are found to be the most abundant. The yield of N-containing tar compounds accounted for approx. 12 % of total tar content. Conditioned pyrolysis gas contained 7.1 g/Nm3 of tar, 0.036 g/Nm3 of NH3 and 119 ppm of H2S. Benzene was by far the most abundant tar compound followed by toluene and styrene. The specifications of the used internal combustion engine were exceeded due to the sum of tar compounds such as fluorantrene and pyrene with 4+ aromatic rings (at 0.0015 g/Nm3) and NH3 content The effectiveness and sustainability of energy recovery in wastewater treatment can be improved using forest industry by-products. | |

Adsorption of six contaminants of emerging concern (CECs) - caffeine, chloramphenicol, carbamazepine, bisphenol A, diclofenac, and triclosan - from a multicomponent solution was studied using activated biochars obtained from three lignocellulosic feedstocks: wheat straw, softwood, and peach stones. Structural parameters related to the porosity and ash content of activated biochar and the hydrophobic properties of the CECs were found to influence the adsorption efficiency. For straw and softwood biochar, activation resulted in a more developed mesoporosity, whereas activation of peach stone biochar increased only the microporosity. The most hydrophilic CECs studied, caffeine and chloramphenicol, displayed the highest adsorption (22.8 and 11.3 mg g-1) onto activated wheat straw biochar which had the highest ash content of the studied adsorbents (20 wt%). Adsorption of bisphenol A and triclosan, both relatively hydrophobic substances, was highest (31.6 and 30.2 mg g-1) onto activated biochar from softwood, which displayed a well-developed mesoporosity and low ash content. | |

Magnetic carbons can significantly lower the costs of wastewater treatment due to easy separation of the adsorbent. However, current production techniques often involve the use of chlorinated or sulfonated Fe precursors with an inherent potential for secondary pollution. In this study, ochre, an iron-rich waste stream was investigated as a sustainable Fe source to produce magnetic activated biochar from two agricultural feedstocks, softwood and wheat straw. Fe doping resulted in significant shifts in pyrolysis yield distribution with increased gas yields (+50%) and gas energy content (+40%) lowering the energy costs for production. Physical activation transformed ochre to magnetite/maghemite resulting in activated magnetic biochars and led to a 4-fold increase in the adsorption capacities for two common micropollutants - caffeine and fluconazole. The results show that Fe doping not only benefits the adsorbent properties but also the production process, leading the way to sustainable carbon adsorbents. | |

The majority of the sludge from the treatment of wastewater in milk processing plants is land spread. The drawbacks of land spreading include local oversupply due to high transport costs, which results in sludge being spread on lands in the vicinity of the dairy factories. Local oversupply can lead to accumulation of certain substances in soil through annual application over many years. Therefore, in the long term, there is a need for alternative methods to recover energy and nutrients from increasing volumes of sludge generated from dairy processing. Pyrolysis offers a potential alternative to land spreading, which can reduce health and environmental risks, while providing an avenue for the recovery of energy and nutrients. Pyrolysis allows energy recovery in the form of a high calorific value pyrolysis gas and a char which may be used as a soil amendment. In this study pyrolysis of dried dairy sludge was carried out at pilot scale. The results indicate that a dried biological sludge can be successfully pyrolysed and when mixed with wood the resulting char meets European Biochar Certificate criteria regarding carbon content. Most of the initial energy content of the feedstock was retained in the pyrolysis gas prior to cleaning, 53%, compared to 34.5% in the char and 1.5% in the tar. For the pyrolysis gas after cleaning (mainly cracking in presence of air) the initial energy content of the feedstock retained in the gas was only slightly higher than that retained in the char, 39.2% versus 34.5%, while the tar accounted for 0.8% of the initial energy content. | |

Eucalypts can be very productive when intensively grown as short rotation woody crops (SRWC) for bioproducts. In Florida, USA, a fertilized, herbicided, and irrigated cultivar planted at 2471 trees/ha could produce over 58 green mt/ha/year in 3.7 years, and at 2071 trees/ha, its net present value (NPV) exceeded $750/ha at a 6% discount rate and stumpage price of $11.02/green mt. The same cultivar grown less intensively at three planting densities had the highest stand basal area at the highest density through 41 months, although individual tree diameter at breast height (DBH) was the smallest. In combination with an organic fertilizer, biochar improved soil properties, tree leaf nutrients, and tree growth within 11 months of application. Biochar produced from Eucalyptus and other species is a useful soil amendment that, especially in combination with an organic fertilizer, could improve soil physical and chemical properties and increase nutrient availability to enhance Eucalyptus tree nutrition and growth on soils. Eucalypts produce numerous naturally occurring bioproducts and are suitable feedstocks for many other biochemically or thermochemically derived bioproducts that could enhance the value of SRWCs. | |