Use of Tangential Flow Filtration (TFF) in the Downstream Processing Activities of Bioprocesses

Downstream Processing

Downstream-processing in bioprocesses concerns the ways in which output streams (e.g. solid, liquid, slurry etc.) are handled and the means for the recovery and purification of the targeted products. It is a crucial step in bioprocess development that is often overlooked, especially in early stages of research and development, where much of the focus tends to be on optimizing the bioconversion process itself. This is a critical oversight given that downstream processing can account for a large portion (sometimes up to 80%) of the total production costs, particularly in processes dealing with dilute concentrations of the target product or complex mixtures.Importance in Bioprocesses

Giving due focus to downstream processing in bioprocess development can not only lead to better product recovery and quality but also to significant cost savings and improved sustainability. This is especially important in processes concerning the valorisation of lignocellulosic feedstocks, where the complexity of the feedstock and the need for high-purity end products can make the downstream process a significant factor in the overall economic viability of the process.Click below to read more about bioprocess development for downstream processing activities.

Get more info...Downstream Processing

Background

Tangential Flow Filtration (TFF), also known as cross-flow filtration, has increasingly gained prominence in the field of bioprocess development due to its robustness, scalability, and versatility.Tangential Flow Filtration involves passing the feed stream tangentially across the surface of the membrane, which helps to continuously sweep away accumulated materials, thus minimising membrane fouling. This distinctive characteristic has led to the wide application of TFF in bioprocesses.

In the context of bioprocess development TFF has several few important applications in downstream processing, including:

- Clarification - TFF can be used to separate cells or cell debris from the rest of the culture broth after fermentation, yielding a clarified liquid that contains the target biomolecules.

- Concentration - TFF is often used to concentrate dilute solutions of target biomolecules. This is accomplished by allowing water and small solutes to pass through the membrane while retaining larger biomolecules, thereby increasing their concentration in the retentate.

- Dialysis/Buffers Exchange - TFF can also be used to change the buffer of a solution or to remove small contaminants. This is often an important step before or after other processing steps, like chromatography.

Important Aspects in TFF

- Membrane Selection - The type of membrane used in Tangential Flow Filtration is crucial. The selection of membrane material, pore size, and surface properties needs to be optimised based on the feed stream characteristics and the target product. The membrane should be chemically resistant to the feed and cleaning solutions, have an appropriate pore size for the separation task, and be able to maintain high flux rates.

- Operating Parameters - Operating conditions like transmembrane pressure, cross-flow velocity, and temperature should be adjusted for optimal performance. A balance must be struck between achieving high throughput and maintaining product quality and membrane lifespan.

- Shear Sensitivity - The shear sensitivity of the product should be assessed. Some bioproducts, such as cells or certain proteins, may be damaged under high-shear conditions, which could affect product yield and quality. The cross-flow velocity might need to be adjusted to accommodate these sensitivities.

- Process Integration - The TFF process should be compatible with upstream processes and should facilitate subsequent downstream steps. Moreover, the TFF system configuration, whether it is single-stage or multi-stage, should align with the process requirements.

- Scalability - Parameters established during development or pilot scale should translate effectively to larger-scale operations to ensure successful scale-up.

- Costs - Both CAPEX and OPEX costs of TFF should be evaluated. This includes the cost of the membrane and TFF equipment, energy costs, and costs for membrane replacement or cleaning.

- Cleaning and Maintenance - Effective cleaning protocols are critical to maintain membrane performance and lifespan. Cleaning-in-place (CIP) methods, which may involve backflushing, chemical cleaning, or other strategies, should be developed and optimised.

- Regulatory Considerations - For bioprocesses intended for food, pharmaceutical, or medical applications, TFF processes should comply with regulatory standards including those related to product purity, contamination control, and process validation.

Advantages of TFF

- Minimized Membrane Fouling - In TFF, the feed flow is directed parallel to the filtration membrane surface, which prevents the accumulation of particulate matter on the membrane, significantly reducing the extent of membrane fouling. This property allows for sustained performance during lengthy operation periods.

- High Product Recovery - Tangential Flow Filtration systems can provide high product recovery rates. Since the product and the retentate stream move in the same direction, there is a lower risk of product loss compared to normal (dead-end) filtration methods.

- Process Flexibility - TFF allows for the simultaneous concentration and purification of a biological product, enhancing the overall process efficiency. It is versatile and can be adapted to handle a wide range of feedstock characteristics, and is suitable for various applications, including protein concentration, cell harvesting, and virus filtration.

- Scalability - Tangential Flow Filtration systems are easily scalable from laboratory to industrial scale, making it a suitable choice for bioprocess development. Parameters established during the development or pilot scale can be translated to larger systems, reducing the time and costs associated with process scale-up.

- Controlled Shear Rate - In TFF, the shear rate can be precisely controlled by adjusting the feed flow rate, which can be critical for handling shear-sensitive biomolecules or cells.

- Continuous Operation - TFF is designed for continuous operation, making it suitable for large-scale, industrial processes. This can lead to increased productivity and more efficient use of equipment.

Disadvantages of TFF

- Operational Complexity - TFF systems are generally more complex to operate compared to normal (dead-end) filtration systems. They require precise control of multiple parameters, such as transmembrane pressure, cross-flow velocity, and temperature, to ensure optimal performance.

- Higher Initial Investment - The cost of setting up a TFF system can be higher due to the need for specialized equipment and membranes. This includes the cost of pumps capable of providing the high feed flow rates required in TFF, and the cost of robust control systems to maintain optimal operating conditions.

- Membrane Fouling and Concentration Polarization - Despite the reduced fouling compared to dead-end filtration, membrane fouling can still occur in TFF, especially with complex biological feedstocks. Concentration polarization, where solutes accumulate at the membrane surface, can also occur and may lead to reduced filtration performance over time.

- Energy Consumption - TFF systems often require higher energy consumption compared to normal filtration due to the need for high cross-flow velocities to maintain the tangential flow across the membrane.

- Shear Stress - While the shear rate in TFF can be controlled, high shear rates may be detrimental to shear-sensitive cells or molecules, potentially leading to product degradation or loss of viability.

- Maintenance Requirements - Regular cleaning and maintenance of the TFF system are required to ensure consistent performance over time. Depending on the complexity of the feedstock and the nature of the fouling, this might involve backflushing, chemical cleaning, or even membrane replacement.

We have several items of Tangential Flow Filtration that allow us to handle downstream processing activities up to TRL6. Some of the relevant TFF equipment that we have are detailed below.

Millipore ProFlux M30 TFF System

The ProFlux M30 Tangential Flow Filtration System can utilise spiral-wound cartridges, hollow fiber cartridges, or cassette membrane modules. The system's control panel displays crucial process data and incorporates safety features that allow manual handling of tangential ultrafiltration and microfiltration applications. The unit allows control over pump speed and backpressures according to the requirrments of the process and membranes.This model of equipment has been widely used in the pharmaceutical and biotechnology industry for research & development, pilot, and production processes.

Millipore Pellicon 2

The Millipore Pellicon 2 system is a lab-scale TFF system that uses ultrafiltration and microfiltration cassette membranes, which are characterized by their low hold-up volume, high surface area, and robust performance. These cassette membranes, which are available in a variety of pore sizes and materials, provide effective and scalable solutions for the processing of biological products, including proteins, antibodies, and viruses.The Pellicon 2 system is used in a wide variety of fields, including pharmaceutical and biotechnology industries, for both research & development and production applications. Its high performance, scalability, and the ability to maintain product quality make it a popular choice for bioprocessing tasks.

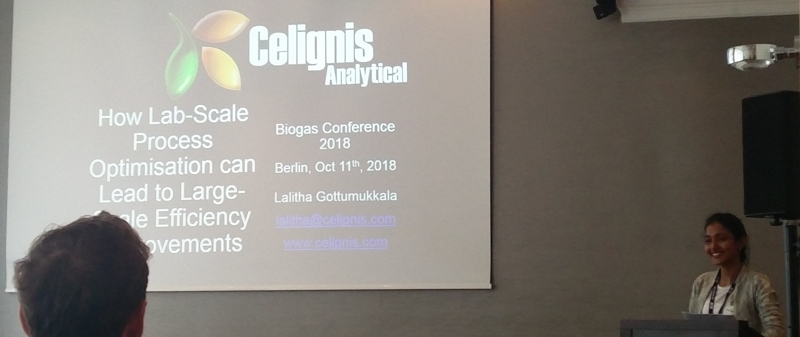

Lalitha Gottumukkala

Founder of Celignis Bioprocess, CIO of Celignis

PhD

<p style="text-align: left;">Has a deep understanding of all biological and chemical aspects of bioproceses. Has developed Celignis into a renowned provider of bioprocess development services to a global network of clients.</p>

Oscar Bedzo

Bioprocess Project Manager & Technoeconomic Analysis Lead

PhD

<p style="text-align: left;">A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.</p>

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

<p style="text-align: left;">Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.</p>