Scaling-up Bioprocesses Up to TRL6

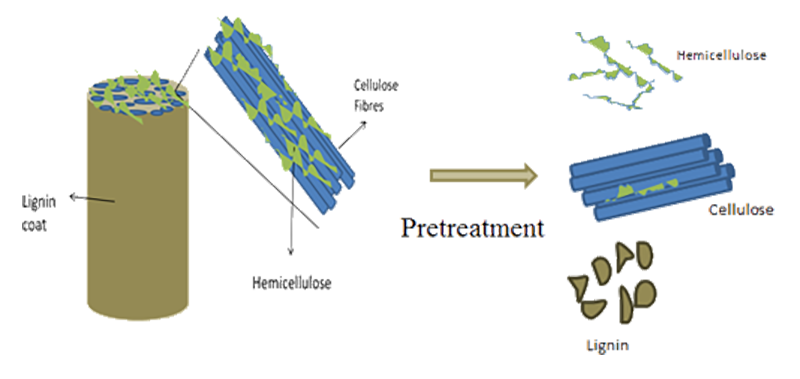

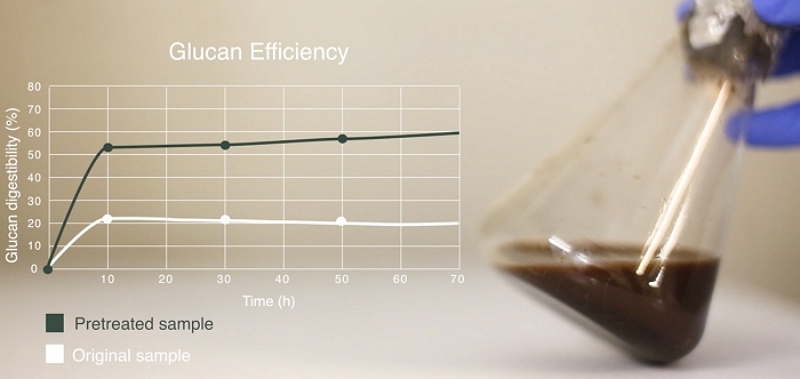

The bioprocess can be a fully vertically-integrated process, involving every stage of processing and conversion, starting from the original feedstock (e.g. corn stover) and ending at the final product (e.g. bioethanol). Alternatively, the bioprocess can be considered to a specific node within a larger sequence of processing steps, for example the pretreatment applied to the corn stover prior to the subsequent hydrolysis and fermentation stages.

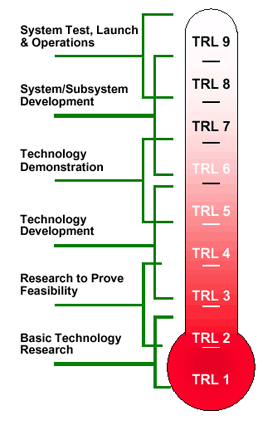

- TRL 1 (Basic principles observed and reported): Here the basic principles underlying the technology are understood. Research is starting to link the principles to potential applications.

- TRL 2 (Technology concept and/or application formulated): Researchers consider potential applications of the basic principles and theoretical studies start to investigate process feasibility.

- TRL 3 (Analytical and experimental critical function and/or characteristic proof-of-concept): Laboratory studies are conducted to validate the concept, and critical technical parameters are identified.

- TRL 4 (Component and/or breadboard validation in a laboratory environment): The technology is developed to the extent that key components can be tested in a laboratory environment. The basic technological components are integrated to establish that the pieces will work together.

- TRL 5 (Component and/or breadboard validation in a relevant environment): The basic technological components are tested in a relevant environment, e.g. a small-scale bioreactor.

- TRL 6 (System/subsystem model or prototype demonstration in a relevant environment): A model or prototype of the system or subsystem is tested in a relevant environment. For a bioprocess, this could mean a pilot-scale demonstration.

- TRL 7 (System prototype demonstration in an operational environment): A system prototype must be demonstrated in an operational environment. In a bioprocess context, this typically means using the technology under industry-relevant conditions.

- TRL 8 (Actual system completed and qualified through test and demonstration): The technology is incorporated into a complete system and tested, demonstrating that it works in its final form under the expected conditions.

- TRL 9 (Actual system proven through successful mission operations): The technology is in its final form and has been proven to work in real-world operations. In the context of a bioprocess, this would mean the process has been successfully implemented at full industrial scale.

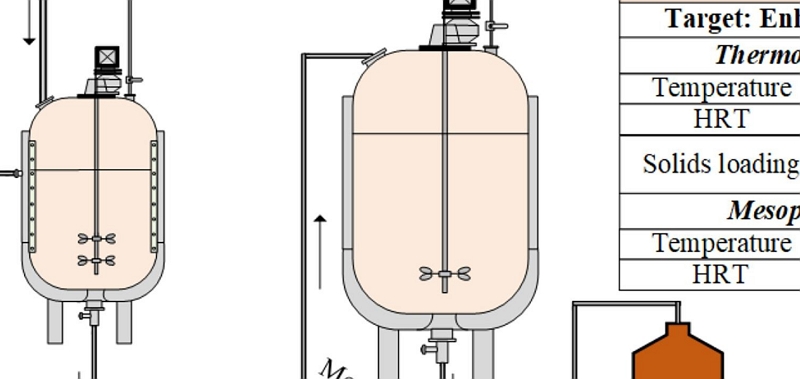

However, once we have optimised the bioprocess at lower TRLs we recommend that the processes are validated at higher TRLs. Doing so will help to ascertain whether the bioprocess can be easily scaled-up, with product yields and quality comparable to the lab-scale experiments, or whether modifications need to be made to the process to ensure it is viable at enhanced TRLs.

Moving up the TRL meter also highlights the importance of developing and testing commercially-viable downstream processing steps (e.g. solids/liquid separations, product recoveries, and waste treatment). These can often be overlooked in bioprocess development projects even though they can often represent a significant proportion of CAPEX and OPEX costs in real-world operations.

We have a wide-array of higher-TRL equipment and infrastructure that allow us to handle these TRL6 projects. Some of the relevant equipment we have are detailed below.

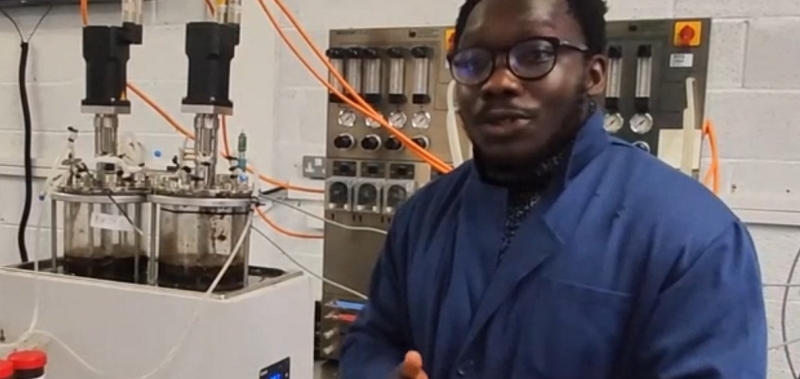

TRL6 Bioreactors

We have dozens of different bioreactors with capacities ranging from 1 litre to 100 litres. Our 100-litre system is manufactured by Sartorius and allows full and precise control of the bioprocess. When using such a system for fermentations we often also use one or more smaller-scale bioreactors (of around 20-litres capacity) to provide the culture seed-train.Please get in touch with us if you would like us to involve our TRL6 bioreactors in a bioprocess development project or for the scale-up of your existing bioprocess.

Tangential Flow Filtration (TFF)

Tangential Flow Filtration (TFF), also known as crossflow filtration, is a widely used technique in bioprocess development for the separation and concentration of biomolecules. Unlike traditional filtration, where the feed solution flows perpendicularly towards the filter, in TFF, the feed solution flows tangentially along the surface of the membrane. This tangential flow prevents the rapid buildup of a concentrated layer ("cake layer") of the retained species on the surface of the membrane, which can lead to membrane fouling and reduced filtration performance.At Celignis we have several items of TFF equipment, suitable for different TRL levels up to TRL6. Our higher-TRL equipment are made by Millipore and can process 10's of litres of liquid per hour.

Click below for more on TFF and its use in bioprocess development.

Get more info...TFF

A filter press is a piece of equipment used in various industries, including bioprocessing, to separate solids and liquids. It consists of multiple filter plates arranged in a frame, which create a series of chambers. The feed slurry (a mixture of liquid and solids) is pumped into these chambers, and the liquid phase passes through the filter cloth, leaving the solid materials behind.

At Celignis we have several items of filter press equipment, suitable for different TRL levels up to TRL6. Our higher-TRL equipment can process 10's of litres of liquid per hour.

Click below for more info on filter presses and their use in bioprocess development.

Get more info...Filter Press

A filter dryer is a piece of equipment used in the pharmaceutical and chemical industries, including in some bioprocessing applications, for solid-liquid separation and subsequent drying of the solid. This device combines filtration and drying in a single unit, which can be beneficial in terms of process integration and reduction of product handling.

At Celignis we have a Sweco PharmASep PH30 Filter Dryer, suitable for pilot-scale operations.

Click below for more info on filter dryers and their use in bioprocess development.

Get more info...Filter Dryers

Supercritical CO2 Extraction System

Supercritical CO2 is CO2 (carbon dioxide) maintained at a temperature and pressure above its critical point, resulting in a state of matter that has properties of both a gas and a liquid. Its density is comparable to that of a liquid, while it diffuses into materials like a gas and has a low viscosity. These properties make supercritical CO2 an excellent solvent for many substances, making it a versatile tool in bioprocess development.At Celignis we have a 5-litre supercritical CO2 extraction system which can be used in higher-TRL projects.

Click below for more info on supercritical CO2 and its use in bioprocess development.

Get more info...Supercritical CO2

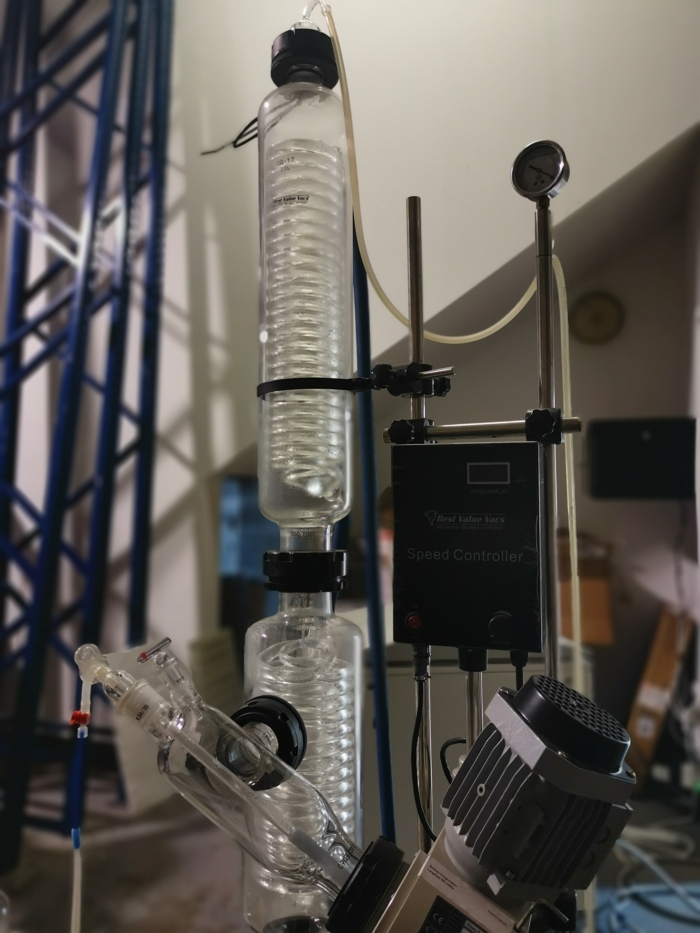

Distillation is a widely-used separation technique in many bioprocesses. It involves heating a liquid mixture to create vapour and then cooling and condensing the vapour to create a separate liquid phase. Different components in the mixture have different boiling points, which allows them to be separated through distillation.

At Celignis we have a 20-litre vacuum distillation system which can be used in higher-TRL projects.

Click below for more info on distillation and its use in bioprocess development.

Get more info...Distillation

Lalitha Gottumukkala

Founder of Celignis Bioprocess, CIO of Celignis

PhD

<p style="text-align: left;">Has a deep understanding of all biological and chemical aspects of bioproceses. Has developed Celignis into a renowned provider of bioprocess development services to a global network of clients.</p>

Oscar Bedzo

Bioprocess Project Manager & Technoeconomic Analysis Lead

PhD

<p style="text-align: left;">A dynamic, purpose-driven chemical engineer with expertise in bioprocess development, process design, simulation and techno-economic analysis over several years in the bioeconomy sector.</p>

Dan Hayes

Celignis CEO And Founder

PhD (Analytical Chemistry)

<p style="text-align: left;">Dreamer and achiever. Took Celignis from a concept in a research project to being the bioeconomy's premier provider of analytical and bioprocessing expertise.</p>

Global Recognition as Bioprocess Experts

Extraction

Pretreatment

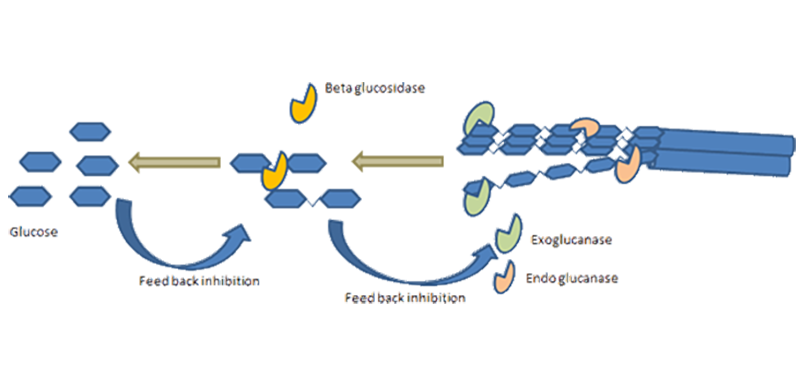

Hydrolysis

Enzymes

Fermentation

Downstream Processing

Lab-Scale Optimisations

Technoeconomic Analyses

Biobased Chemicals

From Process Refinements to an Entire New Process

Research Collaborations

Hydrothermal carbonization (HTC) research has mainly focused on primary char production, with limited attention to secondary char, which is formed through polymerization and condensation of dissolved organic compounds in the liquid phase. This research aims to address this gap via an experimental investigation of the impact of stirring on the mass and carbon balance of HTC reaction products, surface functional groups, and surface morphology of secondary char, using fructose as a model compound. A 3D hydrodynamic simulation model was developed for a two-liter HTC stirred reactor. The experimental results indicated that stirring did not significantly influence the pH, mass, carbon balance, and surface functional groups of secondary char produced under the range of experimental conditions (180 C, 10% biomass to water (B/W) ratio, and a residence time of 0-120 min) studied. Nonetheless, it was observed that a stirring rate of 200 rpm influenced the morphology and shape of the secondary char microspheres, leading to a significant increase in their size i.e., from 1-2 um in unstirred conditions compared with 70 um at a stirring rate of 200 rpm. This increase in size was attributed to the aggregation of microspheres into irregular aggregates at stirring rates > 65 rpm and residence times > 1 h. The hydrodynamic model revealed that high turbulence of Re > 104 and velocities > 0.17 m s-1 correlated with regions of secondary char formation, emphasizing their role in particle aggregation. Particle aggregation is significant above a stirring rate of 65 rpm, which corresponds to the onset of turbulent flow in the reactor. Finally, a mechanism is proposed, based on reactor hydrodynamics under stirred conditions, that explains secondary char deposition on the reactor walls and stirrer. | |

A dried dairy processing sludge (sludge from wastewater treatment of an effluent from a milk processing plant) was pyrolysed in a single-particle reactor at different temperatures from 400 C to 900 C. NH3 and HCN were measured online and offline by means of FTIR as well as by cumulative sampling in impinger bottles (in 0.05 M H2SO4 and 1 M NaOH, respectively) and analysed by photometric method. NO and NO2 were measured online using a nitric oxide analyser while N2O was measured by FTIR. Nitrogen (N) in the sludge and in the remaining char, char-N, was determined. Moreover, tar content in pyrolysis gas was measured and tar-N was determined. The results with respect to N mass balance closure are discussed. The different measurements techniques are compared. For pyrolysis at 520 and 700 nitrogen in the gas phase was mainly contained as N2 (36 % and 40 % respectively), followed by NH3 (15 % and 18 %), tar-N (10 % and 9 %), HCN (1 % and 3 %), NO (1 %) and NO2 (0.2 %). The dairy processing sludge has very specific properties with organic-N present predominantly as proteins and a high content of inherent Ca. These characteristics affected the distribution of N. The amount of char-N was higher while the amount of tar-N lower than for sewage sludge from literature, at comparable pyrolysis temperature. | |

Dairy processing sludge (DPS) is a byproduct generated in wastewater treatment plants located in dairy (milk) processing companies (waste activated sludge). DPS presents challenges in terms of its management (as biosolids) due to its high moisture content, prolonged storage required, uncontrolled nutrient loss and accumulation of certain substances in soil in the proximity of dairy companies. This study investigates the potential of hydrothermal carbonization (HTC) for recovery of nutrients in the form of solid hydrochar (biochar) produced from DPS originating from four different dairy processing companies. The HTC tests were carried out at 160 C, 180 C, 200 C and 220 C, and a residence time of 1h. The elemental properties of hydrochars (biochars), the content of primary and secondary nutrients, as well as contaminants were examined. The transformation of phosphorus in DPS during HTC was investigated. The fraction of plant available phosphorus was determined. The properties of hydrochar (biochar) were compared against the European Union Fertilizing Products Regulation. The findings of this study demonstrate that the content of nutrient in hydrochars (biochars) meet the requirements for organo-mineral fertilizer with nitrogen and phosphorus as the declared nutrients (13.9-26.7%). Further research on plant growth and field tests are needed to fully assess the agronomic potential of HTC hydrochar (biochar). | |

Disposal of waste-activated sludge [dairy processing sludge, (DPS)] from wastewater treatment plants located in milk processing companies is an increasing concern. DPS is usually applied to farmlands in the vicinity of the dairy companies. This practice is becoming unsustainable due to uncontrolled nutrient loss and potential soil contamination. We propose to recover nutrients in the form of biochar. This paper examines the properties of biochars obtained from slow pyrolysis of DPS. DPS samples were pyrolyzed at laboratory and pilot scale at 600 and 700 C. The elemental properties of biochars, the content of primary and secondary nutrients, as well as contaminants were examined and compared against the European Union Fertilizing Products Regulation. The biochars meet the specified limits for hydrogen-to-organic carbon ratio, chloride, and polycyclic aromatic hydrocarbons intended for gasification and pyrolysis component category materials. In six out of eight biochars, the content of phosphorus (P) as a single declared nutrient and the level of contaminants meet those required for an organo-mineral fertilizer. Only two biochars meet the required concentrations of nitrogen, phosphorus, and potassium. A minimum solid content of 30% in DPS is required to make the process of biochar production energetically sustainable. | |

Anaerobically digested sewage sludge mixed with forest residues was pyrolysed at 800 C, at laboratory and pilot scale. The study quantified differences in char and gas yields for tests carried out in a simple fixed bed laboratory reactor and rotating retort pyrolyser at pilot scale, when the residence time of feedstock was 10 min in both cases. The yield of char from pilot scale was 4 % lower than from laboratory scale while the yield of gas was 15.7 % higher. During the pilot scale pyrolysis of anaerobically digested sewage sludge blended with forest residues the gas quality for energy recovery applications was assessed and the fate of impurities (tar, NH3 and H2S) was investigated. The raw pyrolysis gas contained 14.6 g/Nm3 of tar, 36.9 g/Nm3 of NH3 and 793 ppm of H2S. Sixteen N-containing tar species were identified of which pyridine, propenenitrile, 2-methyl-, benzonitrile, and indole are found to be the most abundant. The yield of N-containing tar compounds accounted for approx. 12 % of total tar content. Conditioned pyrolysis gas contained 7.1 g/Nm3 of tar, 0.036 g/Nm3 of NH3 and 119 ppm of H2S. Benzene was by far the most abundant tar compound followed by toluene and styrene. The specifications of the used internal combustion engine were exceeded due to the sum of tar compounds such as fluorantrene and pyrene with 4+ aromatic rings (at 0.0015 g/Nm3) and NH3 content The effectiveness and sustainability of energy recovery in wastewater treatment can be improved using forest industry by-products. | |

Adsorption of six contaminants of emerging concern (CECs) - caffeine, chloramphenicol, carbamazepine, bisphenol A, diclofenac, and triclosan - from a multicomponent solution was studied using activated biochars obtained from three lignocellulosic feedstocks: wheat straw, softwood, and peach stones. Structural parameters related to the porosity and ash content of activated biochar and the hydrophobic properties of the CECs were found to influence the adsorption efficiency. For straw and softwood biochar, activation resulted in a more developed mesoporosity, whereas activation of peach stone biochar increased only the microporosity. The most hydrophilic CECs studied, caffeine and chloramphenicol, displayed the highest adsorption (22.8 and 11.3 mg g-1) onto activated wheat straw biochar which had the highest ash content of the studied adsorbents (20 wt%). Adsorption of bisphenol A and triclosan, both relatively hydrophobic substances, was highest (31.6 and 30.2 mg g-1) onto activated biochar from softwood, which displayed a well-developed mesoporosity and low ash content. | |

Magnetic carbons can significantly lower the costs of wastewater treatment due to easy separation of the adsorbent. However, current production techniques often involve the use of chlorinated or sulfonated Fe precursors with an inherent potential for secondary pollution. In this study, ochre, an iron-rich waste stream was investigated as a sustainable Fe source to produce magnetic activated biochar from two agricultural feedstocks, softwood and wheat straw. Fe doping resulted in significant shifts in pyrolysis yield distribution with increased gas yields (+50%) and gas energy content (+40%) lowering the energy costs for production. Physical activation transformed ochre to magnetite/maghemite resulting in activated magnetic biochars and led to a 4-fold increase in the adsorption capacities for two common micropollutants - caffeine and fluconazole. The results show that Fe doping not only benefits the adsorbent properties but also the production process, leading the way to sustainable carbon adsorbents. | |

The majority of the sludge from the treatment of wastewater in milk processing plants is land spread. The drawbacks of land spreading include local oversupply due to high transport costs, which results in sludge being spread on lands in the vicinity of the dairy factories. Local oversupply can lead to accumulation of certain substances in soil through annual application over many years. Therefore, in the long term, there is a need for alternative methods to recover energy and nutrients from increasing volumes of sludge generated from dairy processing. Pyrolysis offers a potential alternative to land spreading, which can reduce health and environmental risks, while providing an avenue for the recovery of energy and nutrients. Pyrolysis allows energy recovery in the form of a high calorific value pyrolysis gas and a char which may be used as a soil amendment. In this study pyrolysis of dried dairy sludge was carried out at pilot scale. The results indicate that a dried biological sludge can be successfully pyrolysed and when mixed with wood the resulting char meets European Biochar Certificate criteria regarding carbon content. Most of the initial energy content of the feedstock was retained in the pyrolysis gas prior to cleaning, 53%, compared to 34.5% in the char and 1.5% in the tar. For the pyrolysis gas after cleaning (mainly cracking in presence of air) the initial energy content of the feedstock retained in the gas was only slightly higher than that retained in the char, 39.2% versus 34.5%, while the tar accounted for 0.8% of the initial energy content. | |

Eucalypts can be very productive when intensively grown as short rotation woody crops (SRWC) for bioproducts. In Florida, USA, a fertilized, herbicided, and irrigated cultivar planted at 2471 trees/ha could produce over 58 green mt/ha/year in 3.7 years, and at 2071 trees/ha, its net present value (NPV) exceeded $750/ha at a 6% discount rate and stumpage price of $11.02/green mt. The same cultivar grown less intensively at three planting densities had the highest stand basal area at the highest density through 41 months, although individual tree diameter at breast height (DBH) was the smallest. In combination with an organic fertilizer, biochar improved soil properties, tree leaf nutrients, and tree growth within 11 months of application. Biochar produced from Eucalyptus and other species is a useful soil amendment that, especially in combination with an organic fertilizer, could improve soil physical and chemical properties and increase nutrient availability to enhance Eucalyptus tree nutrition and growth on soils. Eucalypts produce numerous naturally occurring bioproducts and are suitable feedstocks for many other biochemically or thermochemically derived bioproducts that could enhance the value of SRWCs. | |