Analysis of Paper and Cardboard

Background on Paper and Cardboard

Paper made from hardwoods tends to be smoother (and therefore easier to write and print on) than paper from softwoods but softwood paper also tends to be weaker. The fibres from hardwoods and softwoods can be blended into a single paper type, with the proportional quantities varying according to preferences for strength, whiteness, and roughness, among other properties.

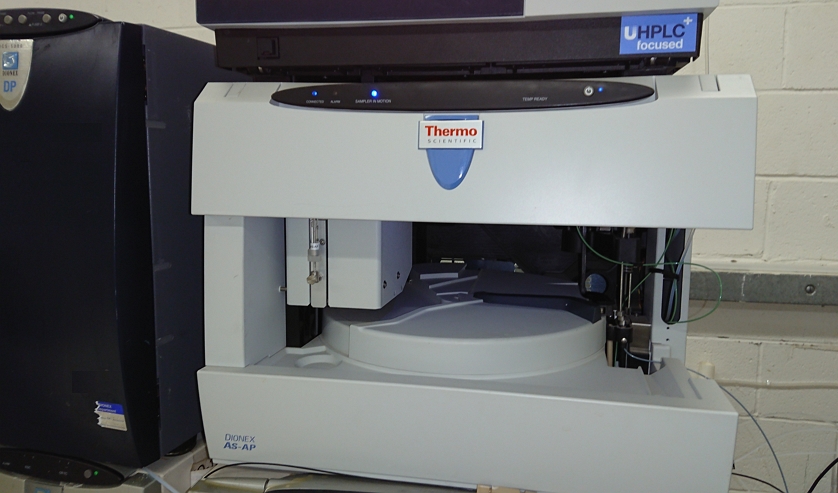

Celignis founder Daniel Hayes has considerable experience in the chemical and near-infrared analysis of papers and cardboards, having undertaken a study, funded by the Irish Environmental Protection Agency, that involved this. That study involved collecting and characterising a wide variety of samples identified, by a previous EPA study, as being major contributors to the paper/cardboard fraction of MSW. Such samples included: newspapers, printing paper, receipts, paper bags, and packaging papers/cardboards.

Analysis of Paper and Cardboard at Celignis

Celignis Analytical can determine the following properties of Paper and Cardboard samples:

Lignocellulosic Properties of Paper and Cardboard

Cellulose Content of Paper and Cardboard

Click here to see the Celignis Analysis Packages that determine Cellulose Content

Request a QuoteCellulose Content

Hemicellulose Content of Paper and Cardboard

Click here to see the Celignis Analysis Packages that determine Hemicellulose Content

Request a QuoteHemicellulose Content

Lignin Content of Paper and Cardboard

Click here to see the Celignis Analysis Packages that determine Lignin Content

Request a QuoteLignin Content

Starch Content of Paper and Cardboard

Click here to see the Celignis Analysis Packages that determine Starch Content

Request a QuoteStarch Content

Uronic Acid Content of Paper and Cardboard

Click here to see the Celignis Analysis Packages that determine Uronic Acid Content

Request a QuoteUronic Acid Content

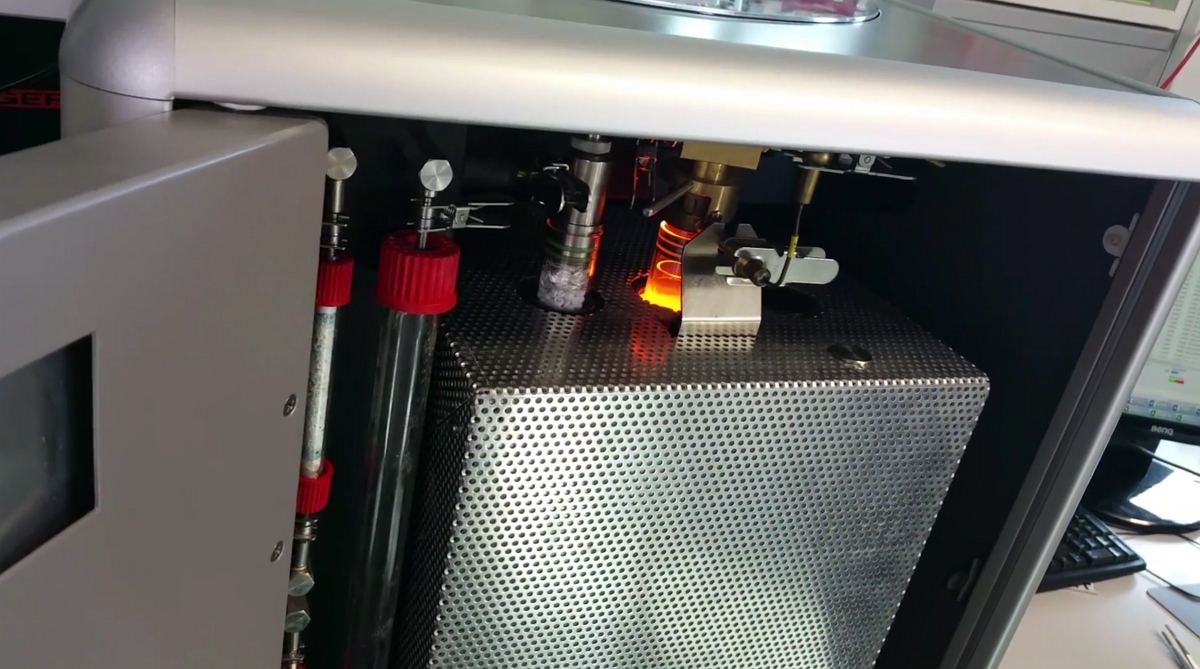

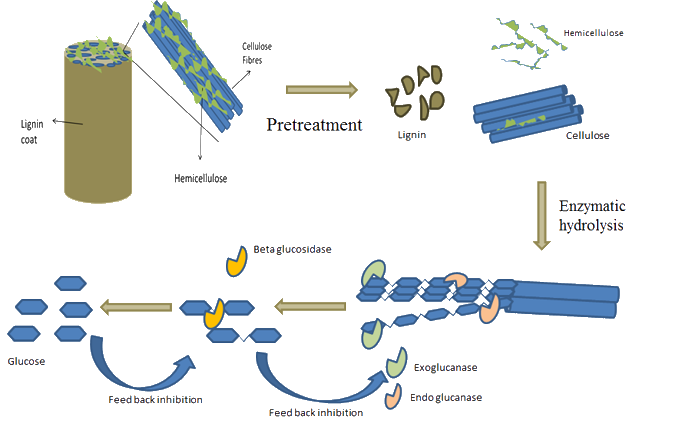

Enzymatic Hydrolysis of Paper and Cardboard

Click here to see the Celignis Analysis Packages that determine Enzymatic Hydrolysis

Request a QuoteEnzymatic Hydrolysis

Bioenergy Properties of Paper and Cardboard

Ash Content of Paper and Cardboard

Click here to see the Celignis Analysis Packages that determine Ash Content

Request a QuoteAsh Content

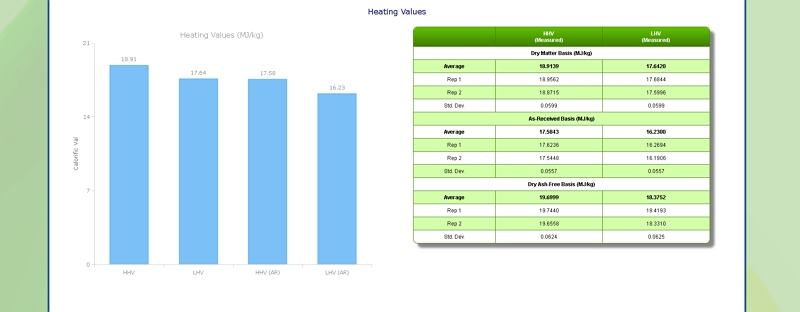

Heating (Calorific) Value of Paper and Cardboard

Click here to see the Celignis Analysis Packages that determine Heating (Calorific) Value

Request a QuoteHeating (Calorific) Value

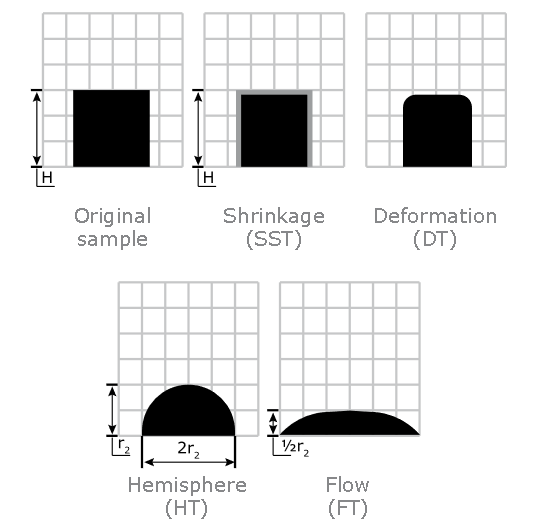

Ash Melting Behaviour of Paper and Cardboard

Ash Shrinkage Starting Temperature (SST) - This occurs when the area of the test piece of Paper and Cardboard ash falls below 95% of the original test piece area.

Ash Deformation Temperature (DT) - The temperature at which the first signs of rounding of the edges of the test piece occurs due to melting.

Ash Hemisphere Temperature (HT) - When the test piece of Paper and Cardboard ash forms a hemisphere (i.e. the height becomes equal to half the base diameter).

Ash Flow Temperature (FT) - The temperature at which the Paper and Cardboard ash is spread out over the supporting tile in a layer, the height of which is half of the test piece at the hemisphere temperature.

Click here to see the Celignis Analysis Packages that determine Ash Melting Behaviour

Request a QuoteAsh Melting Behaviour

Major and Minor Elements in Paper and Cardboard

We can also determine the levels of 13 different minor elements (such as arsenic, copper, and zinc) that may be present in Paper and Cardboard.

Click here to see the Celignis Analysis Packages that determine Major and Minor Elements

Request a QuoteMajor and Minor Elements

Analysis of Paper and Cardboard for Anaerobic Digestion

Biomethane potential (BMP) of Paper and Cardboard

At Celignis we can provide you with crucial data on feedstock suitability for AD as well as on the composition of process residues. For example, we can determine the biomethane potential (BMP) of Paper and Cardboard. The BMP can be considered to be the experimental theoretical maximum amount of methane produced from a feedstock. We moniotor the volume of biogas produced allowing for a cumulative plot over time, accessed via the Celignis Database. Our BMP packages also involve routine analysis of biogas composition (biomethane, carbon dioxide, hydrogen sulphide, ammonia, oxygen). We also provide detailed analysis of the digestate, the residue that remains after a sample has been digested. Our expertise in lignocellulosic analysis can allow for detailed insight regarding the fate of the different biogenic polymers during digestion.

Click here to see the Celignis Analysis Packages that determine BMP

Request a QuoteBMP

Physical Properties of Paper and Cardboard

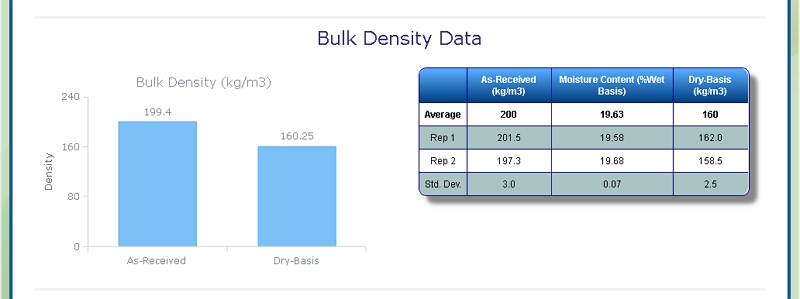

Bulk Density of Paper and Cardboard

At Celignis we can determine the bulk density of biomass samples, including Paper and Cardboard, according to ISO standard 17828 (2015). This method requires the biomass to be in an appropriate form (chips or powder) for density determination.

Click here to see the Celignis Analysis Packages that determine Bulk Density

Request a QuoteBulk Density

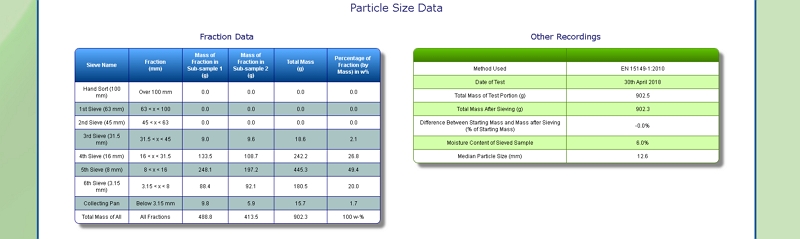

Particle Size of Paper and Cardboard

Our lab is equipped with a Retsch AS 400 sieve shaker. It can accommodate sieves of up to 40 cm diameter, corresponding to a surface area of 1256 square centimetres. This allows us to determine the particle size distribution of a range of samples, including Paper and Cardboard, by following European Standard methods EN 15149- 1:2010 and EN 15149-2:2010.

Click here to see the Celignis Analysis Packages that determine Particle Size

Request a QuoteParticle Size

Disposal of waste sludges produced in large amounts in the pulp and paper industry imposes significant environmental and economical problems. One strategy to address these issues involves revalorization of paper mill sludges by their application as substrates for microbial production of biotechnologically relevant enzymes. The application of lignocellulolytic enzymes in paper, textile and bioenergy industries is encouraged in order to decrease chemicals and energy consumptions. In the following work, deinking sludge was assessed as a substrate for production of lignocellulases. Based on the results of growth and activity screenings, Pleurotus ostreatus PLAB was chosen as the most promising candidate among 30 tested strains and its secretome was further studied by quantitative enzyme assays and mass spectrometry. While endoglucanase and xylanase activities detected in P. ostreatus secretome produced on deinking sludge were similar to activities of cultures grown on other lignocellulosic substrates, average laccase activity was significantly higher (46?000 U/kg DIS). Mass spectrometry identification of the most prominent proteins in the secretome of the target strain confirmed that significant amounts of different lignin-modifying oxidases were produced on this substrate despite its low lignin content, indicating the presence of other inducible compounds. The findings of this study suggest deinking sludge may represent a good substrate for fungal production of the aforementioned enzymes with broad biotechnological applications, including bioremediation, paper and bioenergy industries. | |

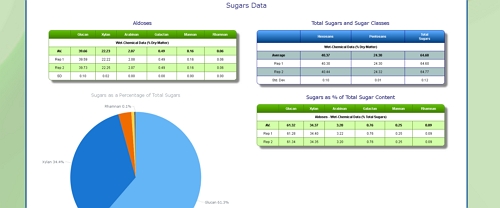

Analytical data and quantitative near infrared (NIR) spectroscopy models for various lignocellulosic components (including Klason lignin and the constituent sugars glucose, xylose, mannose, arabinose, galactose, and rhamnose), ash, and ethanol-soluble extractives, were obtained for 53 samples of paper and cardboard. These samples were mostly the type of materials typically found in domestic wastes (e.g. newspapers, printing paper, glossy papers, food packaging). A number of the samples (48) were obtained by separating a sample, after milling, into two particle size fractions. It was found that the fractions containing the smaller particles typically had higher ash and Klason lignin contents and lower glucose and xylose contents that the larger particle size fractions. Nevertheless, all of the sample types had attractive total sugars contents (>50%) indicating that these could be suitable feedstocks for the production of biofuels and chemicals in hydrolysis-based biorefining technologies. NIR models of a high predictive accuracy (R2 of > 0.9 for the independent validation set) were obtained for total sugars, glucose, xylose, Klason lignin, and ash and with values for the Root Mean Square Error of Prediction (RMSEP) of 2.36%, 2.64%, 0.56%, 1.98%, and 4.87%, respectively. Good NIR models (R2 of > 0.8) were also obtained for mannose, arabinose, and galactose. These results suggest that NIR is a suitable method for the rapid, low-cost, analysis of the major lignocellulosic components of waste paper/cardboard samples. | |

The paper and pulp industry is one of the major industries that generate large amount of solid waste with high moisture content. Numerous opportunities exist for valorisation of waste paper sludge, although this review focuses on primary sludge with high cellulose content. The most mature options for paper sludge valorisation are fermentation, anaerobic digestion and pyrolysis. In this review, biochemical and thermal processes are considered individually and also as integrated biorefinery. The objective of integrated biorefinery is to reduce or avoid paper sludge disposal by landfilling, water reclamation and value addition. Assessment of selected processes for biorefinery varies from a detailed analysis of a single process to high level optimisation and integration of the processes, which allow the initial assessment and comparison of technologies. This data can be used to provide key stakeholders with a roadmap of technologies that can generate economic benefits, and reduce carbon wastage and pollution load. | ||

Paper sludge (PS) from the paper and pulp industry consists primarily of cellulose and ash and has significant potential for ethanol production. Thirty-seven PS samples from 11 South African paper and pulp mills exhibited large variation in chemical composition and resulting ethanol production. Simultaneous saccharification and fermentation (SSF) of PS in fed-batch culture was investigated at high solid loadings and low enzyme dosages. Water holding capacity and viscosity of the PS influenced ethanol production at elevated solid loadings of PS. High viscosity of PS from virgin pulp mills restricted the solid loading to 18% (w/w) at an enzyme dosage of 20 FPU/gram dry PS (gdPS), whereas an optimal solid loading of 27% (w/w) was achieved with corrugated recycle mill PS at 11 FPU/gdPS. Ethanol concentration and yield of virgin pulp and corrugated recycle PS were 34.2 g/L at 66.9% and 45.5 g/L at 78.2%, respectively. | |

Paper sludge samples collected from recycling mills exhibited high ash content in the range of 54.59%–65.50% and glucose concentrations between 21.97% and 31.11%. Washing the sludge reduced the total ash content to between 10.7% and 19.31% and increased the concentration of glucose, xylose and lignin. Samples were screened for ethanol production and fed-batch simultaneous saccharification and fermentation (SSF) was optimised for the washed samples that resulted in highest and lowest ethanol concentrations. Maximum ethanol concentrations of 57.31 g/L and 47.72 g/L (94.07% and 85.34% of the maximum theoretical yield, respectively) was predicted for high and low fermentative potential samples, respectively, and was experimentally achieved with 1% deviation. A generic set of process conditions were established for the conversion of high ash-containing paper sludge to ethanol. Techno-economic analysis based on three different revenue scenarios, together with Monte Carlo analysis revealed 95% probability of achieving IRR values in excess of 25% at a paper sludge feed rate of 15 t/d. Feed rates of 30 t/d and 50 t/d exhibited a cumulative probability of 100%. This study presents the technical feasibility and economic viability of paper mills expansion towards bioethanol production from paper sludge. | |

This document is the result of the evaluation of biomass feedstocks, from Europe and Latin America, that took place as part of the DIBANET project. That project is co-financed from the 7 th Framework Programme for Research and Technological Demonstration of the European Union. (Title: Enhancing international cooperation between the EU and Latin America in the field of biofuels; Grant Agreement No: 227248-2).

| |||

The processing of lignocellulosic materials in modern biorefineries will allow for the

production of transport fuels and platform chemicals that could replace petroleum-derived

products. However, there is a critical lack of relevant detailed compositional information

regarding feedstocks relevant to Ireland and Irish conditions. This research has involved the

collection, preparation, and the analysis, with a high level of precision and accuracy, of a

large number of biomass samples from the waste and agricultural sectors. Not all of the

waste materials analysed are considered suitable for biorefining; for example the total sugar

contents of spent mushroom composts are too low. However, the waste paper/cardboard

that is currently exported from Ireland has a chemical composition that could result in high

biorefinery yields and so could make a significant contribution to Ireland’s biofuel demands. | ||