Analysis of Total Sugars

When the Total Sugars content is predicted using near infrared models a dedicated model is used. This means that the predicted Total Sugars content may not necessarily by equal to the sum of the predicted values for each of the sugars.

Click here to place an order for determining Total Sugars.

Request a QuoteTotal Sugars Content

Analysis Packages for Total Sugars

Total Sugars, Glucose, Xylose, Mannose, Arabinose, Galactose, Rhamnose, Lignin (Klason), Lignin (Acid Soluble), Acid Insoluble Residue, Extractives (Ethanol-Soluble), Extractives (Water-Soluble), Extractives (Exhaustive - Water then Ethanol), Extractives (Water-Insoluble, Ethanol Soluble) , Ash, Ash (Acid Insoluble)

Total Sugars, Glucose, Xylose, Mannose, Arabinose, Galactose, Rhamnose, Lignin (Klason), Lignin (Klason - Protein Corrected), Lignin (Acid Soluble), Acid Insoluble Residue, Extractives (Ethanol-Soluble), Extractives (Water-Soluble), Extractives (Exhaustive - Water then Ethanol), Extractives (Water-Insoluble, Ethanol Soluble) , Ash, Ash (Acid Insoluble), Glucuronic Acid, Galacturonic Acid, 4-O-Methyl-D-Glucuronic Acid, Protein Content of Acid Insoluble Residue, Carbon Content of Acid Insoluble Residue, Hydrogen Content of Acid Insoluble Residue, Nitrogen Content of Acid Insoluble Residue, Sulphur Content of Acid Insoluble Residue, Xylitol, Sucrose, Fructose, Sorbitol, Trehalose

Total Sugars, Glucose, Xylose, Mannose, Arabinose, Galactose, Rhamnose, Lignin (Klason), Lignin (Acid Soluble), Carbon, Extractives (Ethanol-Soluble), Extractives (Water-Soluble), Extractives (Exhaustive - Water then Ethanol), Extractives (Water-Insoluble, Ethanol Soluble) , Ash, Ash (Acid Insoluble), Starch, Pectin, Glucuronic Acid, Galacturonic Acid, 4-O-Methyl-D-Glucuronic Acid

Analytical Procedure for Total Sugars

☑ Step 1: Acid Hydrolysis of the Sample

In the case where three different types of extracted material exist (water-extracted, ethanol-extracted, and water- then ethanol-extracted) then the sample that has undergone both water and ethanol extraction is typically used for acid hydrolysis, unless otherwise requested by the customer.

The following steps are involved in the acid hydrolysis of a sample.

1. The moisture content of the sample is determined, in duplicate.

2. Approximately 300 mg (with the exact weight noted) of the sample is added to a pressure tube.

3. 3.00 mL of 72% H2SO4 is added by means of an automatic titrator, the weight of the acid added is noted.

4. The sample is mixed thoroughly with the acid using a glass rod, care is taken that no sample stays adherent to the sides of the tube, but instead stays in contact with the acid.

5. The tube is transferred to a water bath that is maintained at 30 degrees celcius.

6. Steps 2-5 are repeated for the duplicate sample.

7. Every 10 minutes the glass rod for each pressure tube is stirred so that the acid reaches all parts of the sample and complete hydrolysis occurs. This is a crucial step.

8. Exactly one hour after it is placed in the water bath the pressure tube is removed and placed on a scales and 84 mL of water added (with the weight of the added water recorded). Any acid/sample on the rod is removed from the rod at this point using this water.

9. A lid is screwed on the tube and the tube is inverted several times to ensure thorough mixing of the acid.

10. Two sugar recovery solution (SRS) pressure tubes are prepared in order to monitor the sugar-loss associated with the second-stage-hydrolysis. This involves the following steps:

(a) 348 microlitres of 72% H2SO4 is added to a test tube containing a solution containing a known weight (approximately 10 g) of a sugar standard. This standard should be of a similar sugar composition to that expected of the samples being analysed. The acid and sugar solution are thoroughly mixed.

(b) The sugar-acid mixture is transferred to a pressure tube which is then sealed.

11. All SRS and sample pressure tubes are placed in an autoclave which is run at 121 degrees celcius for 60 minutes.

12. After the temperature in the autoclave drops to under 80C the tubes are removed and are left (closed) in the lab until they reach room temperature.

13. The hydrolysates are then filtered (using vacuum suction) through filter crucibles of known weight and the resulting filtrate is stored.

14. Any residual solids are washed out from the tube using deionised water until all the Acid Insoluble Residue resides on the filter crucible.

☑ Step 2: Hydrolysate Dilution and Storage

☑ Step 3: Chromatographic Analysis of the Hydrolysate

Equipment Used for Total Sugars Analysis

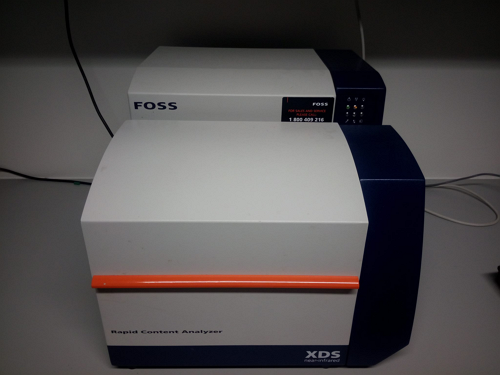

NIR Spectrophotometers

We have several FOSS XDS NIR devices. These have solid content modules, that can allow for samples of a heterogenous particle to be analysed, and liquid modules that allow liquids to be analysed via transmittance spectroscopy.

Ion Chromatography

A Dionex ICS-3000 system that is equipmed with electrochemical, conductivity, and ultraviolet-visible detectors.

Autoclave

An autoclave is used in the protocols for the determination of the lignin and structural sugars (cellulosic and hemicellulosic) contents of samples.

NIR Model

| Total Sugars Global 1 | |

| Min. Value (%) | 7.51 |

|---|---|

| Max. Value (%) | 100.00 |

| Calibration Samples | 452 |

| Validation Samples | 154 |

| R2 (Validation) | 0.9789 |

| RMSEP (%) | 2.4136 |

| Bias (%) | -0.0858 |

| SEP (%) | 2.4199 |

| RPD | 6.8443 |

| RER | 35.4265 |

Analytical data and quantitative near infrared (NIR) spectroscopy models for various lignocellulosic components (including Klason lignin and the constituent sugars glucose, xylose, mannose, arabinose, galactose, and rhamnose), ash, and ethanol-soluble extractives, were obtained for 53 samples of paper and cardboard. These samples were mostly the type of materials typically found in domestic wastes (e.g. newspapers, printing paper, glossy papers, food packaging). A number of the samples (48) were obtained by separating a sample, after milling, into two particle size fractions. It was found that the fractions containing the smaller particles typically had higher ash and Klason lignin contents and lower glucose and xylose contents that the larger particle size fractions. Nevertheless, all of the sample types had attractive total sugars contents (>50%) indicating that these could be suitable feedstocks for the production of biofuels and chemicals in hydrolysis-based biorefining technologies. NIR models of a high predictive accuracy (R2 of > 0.9 for the independent validation set) were obtained for total sugars, glucose, xylose, Klason lignin, and ash and with values for the Root Mean Square Error of Prediction (RMSEP) of 2.36%, 2.64%, 0.56%, 1.98%, and 4.87%, respectively. Good NIR models (R2 of > 0.8) were also obtained for mannose, arabinose, and galactose. These results suggest that NIR is a suitable method for the rapid, low-cost, analysis of the major lignocellulosic components of waste paper/cardboard samples. | |

Analytical data and quantitative near infrared (NIR) spectroscopy models for various lignocellulosic components (including Klason lignin and the constituent sugars glucose, xylose, mannose, arabinose, galactose, and rhamnose), moisture, and ash were obtained for 53 peat samples. These included samples with high, medium, and low degrees of humification. Klason lignin was the main constituent and was greatest in the samples classified as being highly humified, with structural sugars the lowest in this class. The total sugars contents of all samples were considered to be insufficient to allow for their use in biorefining hydrolysis processes for the production of chemicals and biofuels. NIR models were developed for spectral datasets obtained from the samples in their unprocessed (wet), dry and unground, and dry and ground states. Typically the most accurate models were based on the spectra of dry and ground samples. However the NIR models for the wet samples still offered reasonable predictive capabilities. All models were suitable at least for sample screening, with the models for total sugars, glucose, xylose, galactose, and moisture suitable for quantitative analyses. | |

Miscanthus plants were sampled from several plantations in Ireland over the harvest window (October-April). These were separated into their anatomical components and the loss of leaves monitored. Three distinct phases were apparent: there was minimal loss in the "Early" (October to early December) and "Late" (March and April) phases, and rapid leaf loss in the interim period. Samples were analysed for constituents relevant to biorefining. Changes in whole-plant composition included increases in glucose and Klason lignin contents and decreases in ash and arabinose contents. These changes arose mostly from the loss of leaves, but there were some changes over time within the harvestable plant components. Although leaves yield less biofuel than stems, the added biomass provided by an early harvest (31.9-38.4%) meant that per hectare biofuel yields were significantly greater (up to 29.3%) than in a late harvest. These yields greatly exceed those from first generation feedstocks. | |

Miscanthus samples were scanned over the visible and near infrared wavelengths at several stages of processing (wet-chopped, air-dried, dried and ground, and dried and sieved). Models were developed to predict lignocellulosic and elemental constituents based on these spectra. The dry and sieved scans gave the most accurate models; however the wet-chopped models for glucose, xylose, and Klason lignin provided excellent accuracies with root mean square error of predictions of 1.27%, 0.54%, and 0.93%, respectively. These models can be suitable for most applications. The wet models for arabinose, Klason lignin, acid soluble lignin, ash, extractives, rhamnose, acid insoluble residue, and nitrogen tended to have lower R(2) values (0.80+) for the validation sets and the wet models for galactose, mannose, and acid insoluble ash were less accurate, only having value for rough sample screening. This research shows the potential for online analysis at biorefineries for the major lignocellulosic constituents of interest. | |

The processing of lignocellulosic materials in modern biorefineries will allow for the

production of transport fuels and platform chemicals that could replace petroleum-derived

products. However, there is a critical lack of relevant detailed compositional information

regarding feedstocks relevant to Ireland and Irish conditions. This research has involved the

collection, preparation, and the analysis, with a high level of precision and accuracy, of a

large number of biomass samples from the waste and agricultural sectors. Not all of the

waste materials analysed are considered suitable for biorefining; for example the total sugar

contents of spent mushroom composts are too low. However, the waste paper/cardboard

that is currently exported from Ireland has a chemical composition that could result in high

biorefinery yields and so could make a significant contribution to Irelandís biofuel demands. | ||